Introduction

You’ve probably experienced it: on a dry winter’s day, you touch a door handle – and get a shock of static electricity on your fingers. That spark is as harmless as it is unpleasant in everyday life, but in a production hall with fine dust it can be enough to trigger an explosion.

That is why ATEX safety is not only about filters, motors and zones – but about something more fundamental: can the electrical charge escape?

This is where Ohm comes in.

What is an Ohm – and why did Georg Ohm invent it?

In the early 1800s, scientists faced a problem: they could make sparks and light lamps, but they could not predict how electricity moved. Where did it flow easily – and where was it stopped?

Georg Ohm found the answer. He showed through his research that electricity can be understood as a circuit with three simple concepts:

- Voltage is like the pressure in a water tap – how hard the water (or charge) is pushed forward.

- Current is the water itself flowing in the pipe – the amount of electricity moving.

- Resistance is the pipe itself – if it is wide and smooth, the water flows easily; if it is narrow or filled with obstacles, the flow is slowed down.

To make it measurable, he introduced a unit: Ohm (Ω). It tells us how much resistance a connection gives electricity.

And what does that have to do with ATEX?

It is the exact same principle we use today:

- If resistance is low, static electricity can flow away to ground – the building’s common electrical zero point where excess disappears harmlessly.

- If resistance is high, the charge cannot escape. It stays in the metal, plastic or dust – until it suddenly jumps across as a spark.

Grounding in Practice

A green-yellow wire in the chassis means nothing if you cannot measure that there is low resistance all the way through the system.

The ATEX standards are clear:

- EN 60079-32-2 requires that grounding resistance is ≤ 10⁶ Ω.

- EN 17348:2022 requires that parts in direct contact with the dust stream – e.g. hoses and filters – have a resistance of < 10⁸ Ω.

It is not about wires on paper, but about real electrical continuity – unbroken connection all the way from motor housing, wheels and hoses to ground.

Equipotential Bonding – and Why It’s Not Enough

Equipotential bonding means that all metal parts have the same electrical potential – like standing on the same step of a staircase. Then electricity cannot jump “down” and create sparks. But it does not remove the charge: without a low-resistance path to ground, the charge remains and can leap into the air as a spark.

Typical Mistakes and Myths

- “There is a ground wire – so we are safe”

No, only if resistance can be measured low enough. Paint, rust or plastic can break the connection. - “Hoses are just plastic – it’s fine”

No, insulating hoses (ordinary plastic without conductive material) can build up charge. Use hoses with embedded metal wire or conductive plastic, so resistance is low enough. - “Zone 22 is not dangerous”

Even a thin dust layer – not thicker than you can write your name in it – can ignite from a static spark.

When Static Electricity Starts Explosions

Static electricity has been documented as the only ignition source in many incidents:

- An operator tipped powder from a plastic sleeve into a metal container. The static charge on the sleeve produced a spark on contact and ignited a dust cloud. (Source: chemicalukexpo.com)

- A historic incident from 1785 in Giacomelli’s Bakery shows an early documented dust explosion – static charge ignited flour dust. (Source: newson-gale.com)

- According to HSE (UK), even small sparks from static electricity can ignite explosive dust mixtures. (Source: hse.gov.uk)

- NFPA’s review of incidents 2010–2020 shows static electricity is often a suspected ignition source. (Source: kclpure.kcl.ac.uk)

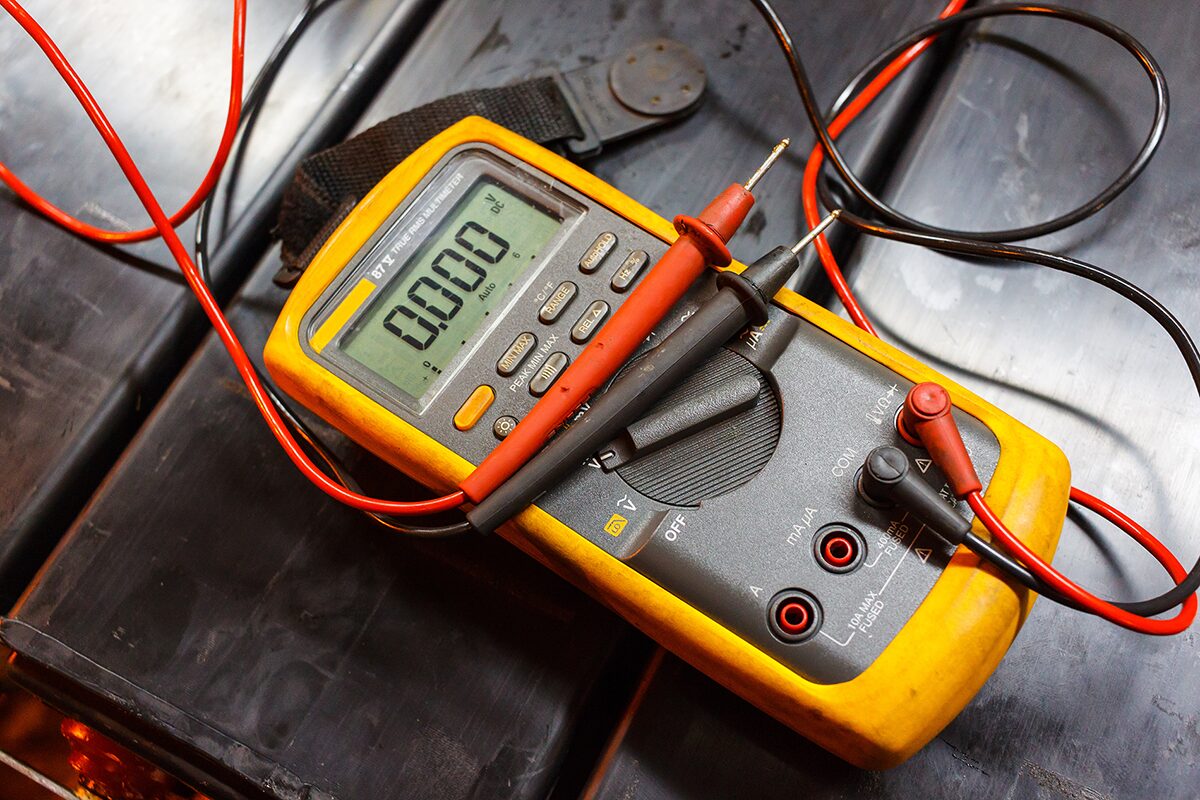

How to Measure

It does not require laboratory equipment – a simple digital multimeter or ground resistance meter is enough. What matters is that the instrument can measure at least up to 10 MΩ.

- Connect one lead to the ground terminal on the chassis.

- Connect the other to the point you want to test – e.g. a wheel, motor housing or hose.

- Measure resistance. The value must be below 10⁶ Ω.

Example:

- Motor housing → ground: 0.3 kΩ → approved

- Hose → ground: 5.4 MΩ → not approved

The measurements should be documented in a log – with date, location and result.

FAQ – Most Common Questions

- How often should I measure?

After risk assessment – typically annually or after service/replacement. - How do I document?

Write down the measured values and keep them with the ATEX documentation. - What if the value is too high?

Then the equipment is not safe in ATEX zones. It must not be used until corrected. - Which instrument should I use?

A calibrated multimeter or a ground resistance tester. - Who may perform the measurement?

Anyone familiar with the equipment, but documentation should be handled by the person responsible for ATEX. - Do I need to measure both hoses and nozzles?

Yes – all parts that may come into contact with dust flow must be tested.

Conclusion

Almost 200 years ago, Georg Ohm gave us a simple insight: High resistance = poor connection. Low resistance = safe discharge.

Today, that is the difference between harmless vacuuming – and a potential explosion.

When you know your Ohm, you know your risk.

And when you can document it, you can run a safe process.

At Particulair we help with measurement, guidance and documentation – not for paperwork’s sake, but because static electricity must never be allowed to be the spark that starts it all.

If you have any questions, feel free to contact us.

Thomas Lyngskjold

August, 2025