Imagine this: you have invested in an industrial vacuum cleaner for your production. It has a nice ATEX label, and everything looks correct. But what if it does not comply with the standard that actually applies today? Because everything changes – especially when we learn more.

Maybe it is not dangerous. Yet. Maybe you just collect dust – day in, day out – until one day it goes BANG, and someone asks: “Was the equipment approved for Zone 20? Did it have double filtration? Can you document it?” That is precisely the situation EN 17348:2022 was introduced to avoid. In that sense, the standard is just as important as your latest virus update.

Why did ATEX come into being?

To understand why we ended up with yet another standard, the historical context is important. Because, as mentioned: everything changes, especially when we learn more.

Before the ATEX directives there were no common European rules for handling explosive atmospheres. Each member state had its own standards, creating a patchwork of different safety requirements. Companies did not know if their equipment was safe enough when used in other countries. And when accidents happened – which they did – it was often because the different standards did not align.

The French grain silo that became a turning point in dust safety

In southwest France, near the town of Blaye by the Gironde river, stood a large grain silo that played a central role in the region’s agricultural economy. On 20 August 1997, the silo was struck by a violent explosion that instantly turned it into an inferno of flames and collapsing concrete structures.

The explosion started in the silo’s northern hall – an area where fine grain dust had accumulated over time. When an unknown ignition source ignited the particles, the flame front spread with shockwave-like speed through the gallery connecting the many silos.

The destruction was enormous. The flame front moved horizontally through the narrow passages, where a thin layer of dust on the walls was lifted into the air, creating the basis for a secondary – and much more powerful – dust explosion. More than two-thirds of the silo’s 44 chambers collapsed partially or completely, and the upper gallery was leveled to the ground.

The consequences were tragic: 11 people lost their lives, including seven SEMABLA employees, three technicians in the administration building, and a fisherman who was found days later buried in the rubble. Another person was severely injured.

The force of the explosion was felt far away. Projectiles of concrete, metal, and glass were thrown more than 100 meters, and smaller fragments were found up to 500 meters from the site. Several nearby buildings had shattered windows, and local companies reported damage to installations.

The Blaye accident became a crucial wake-up call in European safety thinking. It showed clearly that even a thin layer of dust can trigger a chain reaction of explosions, and that the consequences reach far beyond the production site itself.

The textbook example from Aars: Two explosions – and no lessons learned

The company Dangrønt in Aars began producing wood pellets in 2001. The wood flour was stored in a large hall holding up to 500 tons of material – a massive intermediate depot of combustible dust.

In 2002 the facility exploded for the first time. The explosion destroyed the roof and pushed out walls and doors. A truck driver survived miraculously. Police concluded that a spark from the mill had ignited the dust. The case was closed without further investigation.

But eight years later – in 2010 – the facility exploded again. A front loader ignited the wood flour during a routine task. This time, an employee died from burns. Again, the focus was directed at the equipment, not the processes behind it. The intermediate storage – the core of the problem – was never identified as the cause.

The story of Dangrønt is not just the story of two explosions. It is the story of what happens when we do not learn from the first accident; when no one asks about work practices, design choices, and basic safety.

What exploded was not just wood flour – it was the absence of critical questions.

What do the ATEX directives actually cover?

ATEX 137 (1999/92/EC): Applies to companies and employers. It concerns mapping zones, training staff, and minimizing risks.

ATEX 114 (2014/34/EU): Applies to equipment manufacturers. It defines how products – such as vacuum cleaners – must be designed, tested, and marked.

The name ATEX comes from the French “Atmosphères Explosibles”.

When one dust explosion becomes many – and why it is not a myth

Many imagine that a dust explosion is a single violent event. But in reality, it is often what happens afterwards that causes the most damage.

Even a thin layer of dust under 1 mm can create an explosive atmosphere if dispersed into the air – and it will be, if something explodes elsewhere first. An explosion always creates a pressure wave, like a giant bellows, blowing dust into the air.

When sparks or flames from the first explosion spread, the dispersed dust ignites and creates a secondary dust explosion. This is often the one that destroys buildings and costs lives – a domino effect with catastrophic consequences.

“We’ve never had any problems…”

You may have heard it before – or said it yourself: “We have used the same vacuum cleaner for years. Nothing has ever happened.”

But that is the danger of explosion risks: everything is fine. Until it is not. Explosions are rare – but when they happen, the damage is severe and irreversible. In principle, a bit like insurance. It is never fun to pay for, but the best money ever spent when an accident occurs.

From component certification to overall assessment

So, is it enough that the vacuum cleaner has an ATEX or EX marking – then it must be approved? Yes and no. ATEX marking has long been used as a kind of “seal of trust”. But few know that previously, a manufacturer could certify a single component, e.g., the motor – and still sell the whole machine as ATEX-approved.

With EN 17348:2022 this changed. Now the entire vacuum cleaner must be assessed – from hoses and filters to wheels and seals. It is not enough that one part is safe. The whole system counts. So a shiny label is not enough to protect you and your colleagues.

EN 17348:2022 was officially harmonized with the ATEX directive 2014/34/EU in March 2023. From August 2024, it was also harmonized with the Machinery Directive 2006/42/EC. Thus, the standard is now a key reference for both directives – meaning manufacturers can use it as a “presumption of conformity” when CE marking their equipment.

Dust explosions arise where no one is looking

A technical label is not a guarantee in itself. But neither is the absence of visible dust. Dust explosions often start in places nobody looks.

“There’s no dust in the air – so why zone classify?” Because it is not the visible dust that is dangerous. And even if you feel safe with the equipment, remember that dust often hides where nobody looks.

Dust explosions often begin with fine particles that are almost invisible. They settle in corners, behind machines, under shelves. When something explodes elsewhere, that dust is lifted and ignited by flames and sparks from the first explosion – and suddenly you are in the middle of a secondary explosion.

More than 50% of dust explosions start somewhere other than where the accident takes place. And it is often the secondary explosions that are most dangerous for people, buildings, and machines – because we do not know in which direction an explosion may trigger new ones.

Ventilation and spark-free motors are good – but they do not prevent an explosion from spreading through pipes and containers. That is why your risk assessment must always consider the whole picture.

What EN 17348:2022 requires – and why it matters

Previously, it was enough for an industrial vacuum cleaner to have an ATEX label on the cabinet. Maybe the motor was spark-free, or the hose antistatic. But there was no common standard that gathered requirements for the entire machine – from filtration and tightness to material selection and electrostatic discharge. This made it difficult to know what you were actually buying – and even harder to document safety in practice.

EN 17348:2022 changed that fundamentally. For the first time, a standard sets clear and verifiable requirements for how an industrial vacuum cleaner must be constructed and documented if it is to be used in explosive atmospheres – especially Zone 20. It is no longer just about labels, but about real, measurable properties.

The scope of the standard is also broad. It covers not only traditional vacuums for solid and dry materials, but also wet vacuums, portable units, and both electrically and pneumatically driven models. Its requirements also apply to accessories such as hoses, wheels, and nozzles if they come into contact with the dust stream. In this way, the whole system – not just the machine – is required to meet the same safety standards.

Requirements in EN 17348:2022 – and what they mean for you

Double filtration:

Dust must first be retained in a primary filter (minimum ISO 15E – equivalent to former EN 1822 E11, now defined in ISO 29463. The filter must retain at least 95% of particles sized 0.3–1 µm), and then in a HEPA H14 filter as extra safety. Think of the HEPA filter as the final barrier – it must capture what the first did not.

Zone 20 internally:

The inside of the vacuum cleaner, where dust is collected, must be treated as an explosive atmosphere. This means all internal components must withstand explosive dust-air mixtures without becoming ignition sources.

Dissipation of static electricity:

- Dust can accumulate charge and create sparks. For that reason, two resistance limits apply:

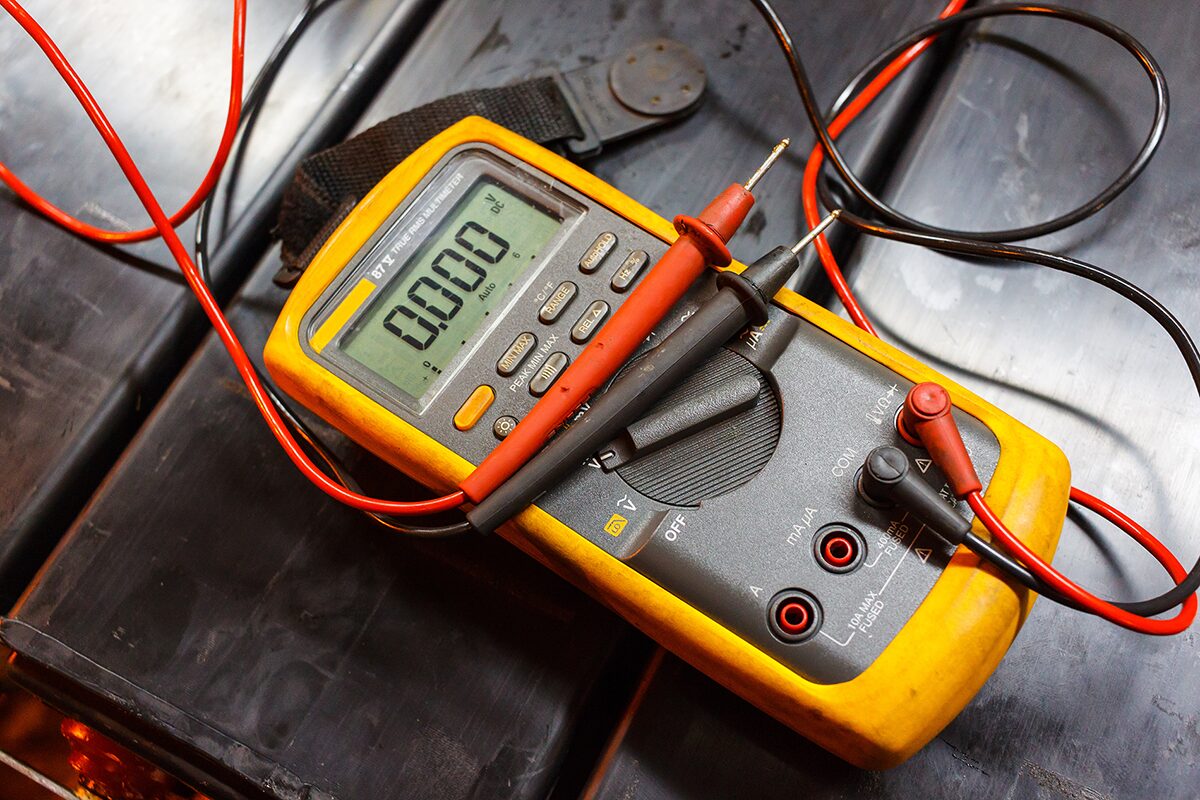

- EN 60079-32-2 requires that the complete equipment – from container and motor housing to frame and wheels – has a total resistance to earth of ≤ 10⁶ Ω.

- EN 17348:2022 adds a specific requirement for components directly in contact with the dust stream, such as hoses, filters and gaskets. Here, the resistance must be < 10⁸ Ω.

Both values must be met and documented by measurement with suitable calibrated instruments.

Tightness and durability:

The vacuum cleaner must be tested to ensure dust does not leak into the motor compartment. It must withstand impacts, wear, and aging – and still be safe years after purchase.

The standard describes detailed test procedures for dust ingress, thermal effects, impact resistance, and aging tests. Existing equipment not tested to EN 17348:2022 can still be used, but new models must comply. Many manufacturers, however, voluntarily update documentation and test results for older models to be more credible during audits and inspections.

A confusion you can feel

As we often see, some manufacturers try to make things as easy as possible for themselves. With ATEX, that can be catastrophic. If marketing twists the wording, the customer may end up with a product that only lives up to the standard on glossy paper. We see this happening right now, which is why you should be cautious when manufacturers refer to Zone 20 and EN 17348:2022.

There are three levels:

- Claiming compliance with EN 17348:2022. Here, the manufacturer has read the standard and judged that their design matches the requirements. This may range from thorough internal testing to a superficial paper review.

- Documenting compliance with EN 17348:2022. Here, test reports, risk assessments, and descriptions of methods (e.g., for earthing, tightness, filtration) are presented.

- Certification by a Notified Body. Here, an independent third party has tested and approved the equipment and issued an official ATEX certificate. This usually applies to Category 1 equipment, where internal Zone 20 is included.

- Our experience is that some manufacturers stop at level 1 – for instance, by just writing in the manual that the machine “complies with EN 17348” – yet market the product as Zone 20 according to the standard. On paper, that may sound correct, but without documentation (level 2) or Notified Body certification (level 3), it is difficult for a buyer to know how thoroughly the requirements have been followed.

As a buyer, you are not entitled to the full technical dossier. But you can ask for documentation showing how the standard has been applied, supported by relevant test results. It is also fair to request certificates for individual components, such as filters.

For you as a buyer, this means you should always demand clear documentation. And if you want to be absolutely safe, choosing equipment certified by a Notified Body is the best option.

Zone 20 – the hidden hazard inside the vacuum cleaner

When people talk about ATEX zones, most think of the room itself – a hall, a production area, or perhaps an enclosed process chamber. But Zone 20 is not only about surroundings. It also concerns what happens inside the vacuum cleaner.

EN 17348:2022 makes it clear that the interior space of a vacuum cleaner – the collection chamber where dust accumulates – must be treated as an explosive atmosphere. This is where fine combustible dust gathers. This is where turbulence can occur. And this is where sparks, hot surfaces, or static electricity can ignite the dust – causing an explosion.

Zone 20 means that an explosive atmosphere is present constantly or frequently. It is not an “emergency state”. It is an expected condition.

This applies, for example, when vacuuming fine plastic, flour, sugar, wood, or metal dust, or when collecting dust in a closed container where it does not disperse to the outside but accumulates over time – quickly surpassing the critical threshold where even less than 1 mm of dust can create an explosive atmosphere.

It also applies when a HEPA filter is used as the final filtration stage. Because the filter is so effective, dust remains trapped in the system instead of leaving. Over time, this creates a high concentration of fine, dry dust – which is the essence of an explosive atmosphere.

Many are surprised to learn that the interior of a vacuum must be treated as a hazardous zone. But that is precisely what distinguishes the old mindset from the new reality: it is not only the surroundings that are dangerous. The equipment itself can also become the point of explosion – if not properly designed.

The legal framework today: ATEX + EN 17348:2022

When discussing ATEX, one often hears: “It is CE-marked, so it is approved.” And yes – CE marking means that the manufacturer declares compliance with applicable legislation. But it says nothing about how. That is why you must know which directive and which standard the product is based on.

The ATEX directive requires that all equipment used in explosive atmospheres (such as vacuums, filters, hoses, etc.) must:

- Be correctly designed, constructed, and tested

- Be marked with zone classification, temperature, and Ex symbol

- Be documented with a technical dossier and a Declaration of Conformity

But the directive does not go into detail about how a vacuum manufacturer must meet these requirements. That is where standards come in. EN 17348:2022 is a harmonized standard under ATEX 2014/34/EU. This means that if a manufacturer complies with the requirements of the standard, they have presumption of conformity with the directive.

In other words: if the vacuum manufacturer follows the standard, they have the strongest possible documentation for legal compliance. It makes it much easier to demonstrate conformity if authorities ask questions.

And this is crucial: if something goes wrong, authorities will not ask: “Did it have a label?” They will ask: “Can you document that it met the requirements?”

In this context, EN 17348:2022 is a lifeline: it gathers requirements in one place and makes it possible to say: “Yes – this vacuum has been tested and documented according to the recognized standard for internal Zone 20.”

Does your vacuum comply with EN 17348:2022?

The quick answer: it is not enough to simply check the Declaration of Conformity. Even if the manufacturer has listed EN 17348:2022 under applied standards, there can be a big difference in how thoroughly the requirements have been followed. As we have seen, there is a difference between claiming compliance and actually documenting it.

But what is a Declaration of Conformity – and where do you find it?

The Declaration of Conformity is the document where the manufacturer formally declares that the product complies with the relevant EU directives and standards. In other words, it is a legally binding guarantee that the equipment meets the law.

It must always include:

- Name and address of the manufacturer

- Which directives the product falls under (e.g., ATEX, Machinery Directive)

- Which standards were applied to demonstrate conformity (e.g., EN 17348:2022)

- Serial number or product type

- Signature of a responsible person at the manufacturer

It is often included in the user manual – so it does not disappear. But it may also be supplied separately in a folder or datasheet.

Either way, it is the most important legal document you have, and you are entitled to receive it upon purchase.

Quick checklist

If you are unsure whether your vacuum cleaner complies with the latest requirements, here is a quick checklist:

- Does it have double filtration (ISO 15E + HEPA H14)?

- Is there documentation for tightness, dust ingress, and aging?

- Is it marked with zone (e.g., Zone 20) and temperature class (e.g., T80 °C)?Can you measure ground resistance below 10⁸ ohm on hoses, wheels, and seals?Is the zone classification mentioned in the user manual or CE declaration?

- Is EN 17348:2022 listed in the Declaration of Conformity under applied standards?

Note: Some of these checks require technical equipment or expertise. Contact your supplier if in doubt about the documentation.

From internal Zone 20 to the bigger ATEX picture

So far, we have focused on the inside of the vacuum cleaner – and the requirements EN 17348:2022 sets for materials, filtration, zone classification, and static electricity dissipation.

That is important. But it is only half the picture. Where the dust comes from – and how it moves in the surrounding space – matters just as much.

A vacuum may be approved for internal Zone 20. But what if it is located in an area where an explosive atmosphere may also arise?

Here, the classic standards still apply, such as EN 60079-10-2 (classification of dust atmospheres) and EN 1127-1 (explosion protection principles). We will not cover them here – but you can read more in our article ATEX ABC, where we explain the zones step by step.

What should you do now?

If you have read this far, you may still be left with more questions than answers – and that is perfectly okay. We know it can feel complex to navigate directives, zone classifications, and new standards like EN 17348:2022. And that is fair – it is not your job to know every detail.

But it is important to know whether the equipment you use is safe – and can be documented as safe.

If in doubt, ask us. We are happy to help you assess whether your solution meets the latest requirements – with no obligation.

The most important thing is not what you choose – but that you can stand behind your choice.

January 2025

Thomas Lyngskjold

Related articles

Process dust requires proximity

The Dust CollectorA dust collector is neither a traditional industrial vacuum cleaner nor a conventional ventilation system. It is a…

94% of Europe’s Shooting Ranges Face Closure

Tightened EU regulations on lead exposure and explosion safety are hitting 20,000 European shooting ranges simultaneously….

Know your Ohm, know your risk

You’ve probably experienced it: on a dry winter’s day, you touch a door handle – and get a shock of…