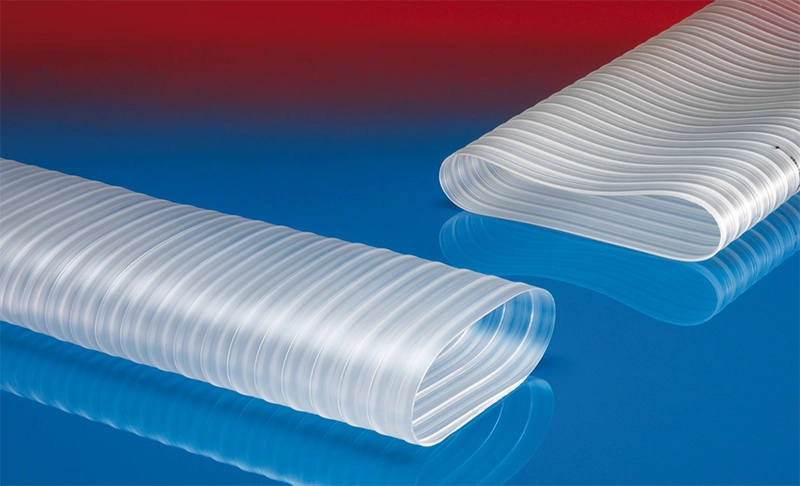

NORRES PROTAPE® PE 322 EC (XLD)

Lightweight electrically conductive PE hose for ATEX – PROTAPE PE 322 EC (XLD)

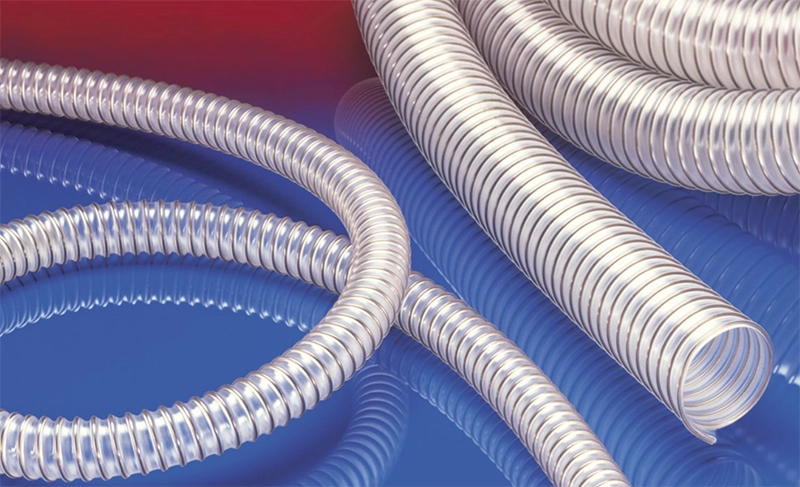

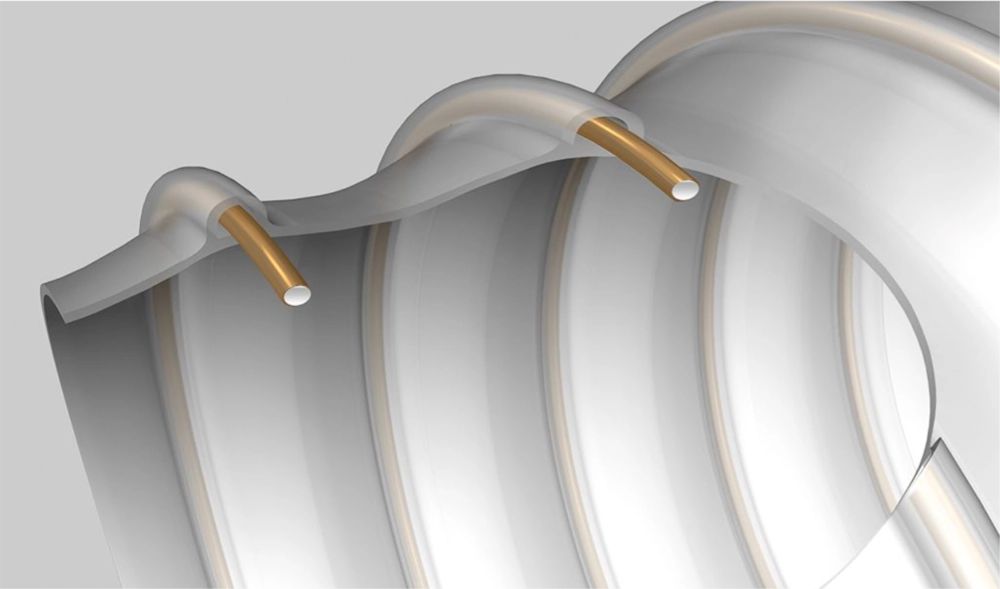

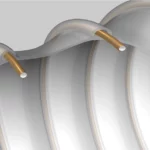

PROTAPE® PE 322 EC (XLD) is a lightweight, electrically conductive polyethylene hose designed for ATEX Zones 20/21/22 and industrial ventilation. The construction with integrated spring steel wire and conductive PE wall (<103 Ω) ensures effective dissipation of static electricity and reduces explosion risk in dust, gas and chemical environments.

High flexibility and low weight

The hose is extremely light, highly flexible and compressible. It offers excellent resistance to acids, alkalis and aggressive chemicals. Suitable for ventilation, extraction of dust, fibres and gases, as well as process and chemical plants with explosion risk. Operating temperature: −35 to +80 °C.

Approved for ATEX and industrial use

PROTAPE PE 322 EC (XLD) complies with ATEX 2014/34/EU, TRGS 727 and RoHS/REACH. Suitable for conveying or extraction in Zones 20, 21, 22 (both inside and outside for dust, powders and vapours) and for flammable media (Zones 0/1/2).

Industrial ATEX ventilation hose?

Contact us for technical advice and correct sizing of conductive, compressible lightweight hoses for ATEX and ESD environments.

Technical note

Construction: PROTAPE® tape hose with integrated spring steel wire and conductive PE wall, thickness 0.3 mm. ATEX and RoHS approved, ESD-safe, lightweight and highly compressible.

FAQ: Lightweight conductive PE hose for ATEX

Which environments is it suitable for?

Used for process extraction, ventilation and transfer of dust, gases and chemical vapours in Zones 20/21/22 and potentially explosive atmospheres.

Is it tested for ESD and ATEX?

Yes, electrical/surface resistance <103 Ω, approved for ATEX, ESD and industrial process ventilation.

How does it differ from heavier ATEX hoses?

PROTAPE PE 322 EC (XLD) is significantly lighter and more flexible – ideal for installations where easy handling and high compressibility are key priorities.

Related links

Technical specifications

| Inner diameter (mm) | Outer diameter (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 40 | 47.00 | 0.470 | 0.280 | 27.00 | 0.15 | 10 | 322-0040-1003 |

| 50–51 | 58.00 | 0.380 | 0.240 | 33.00 | 0.18 | 10 | 322-0050-1003 |

| 60 | 68.00 | 0.315 | 0.190 | 38.00 | 0.21 | 10 | 322-0060-1003 |

| 75–76 | 83.00 | 0.255 | 0.130 | 46.00 | 0.26 | 10 | 322-0075-1003 |

| 80 | 88.00 | 0.240 | 0.120 | 48.00 | 0.29 | 10 | 322-0080-1003 |

| 89–90 | 98.00 | 0.210 | 0.100 | 53.00 | 0.31 | 10 | 322-0090-1003 |

| 100–102 | 108.00 | 0.190 | 0.080 | 58.00 | 0.37 | 10 | 322-0100-1003 |

| 110 | 118.00 | 0.175 | 0.075 | 63.00 | 0.40 | 10 | 322-0110-1003 |

| 120 | 128.00 | 0.160 | 0.070 | 68.00 | 0.44 | 10 | 322-0120-1003 |

| 125–127 | 133.00 | 0.155 | 0.055 | 71.00 | 0.47 | 10 | 322-0125-1003 |

| 140 | 148.00 | 0.135 | 0.050 | 78.00 | 0.52 | 10 | 322-0140-1003 |

| 150–152 | 158.00 | 0.125 | 0.050 | 83.00 | 0.55 | 10 | 322-0150-1003 |

| 160 | 168.00 | 0.120 | 0.045 | 88.00 | 0.58 | 10 | 322-0160-1003 |

| 178–180 | 188.00 | 0.105 | 0.035 | 98.00 | 0.67 | 10 | 322-0180-1003 |

| 200–203 | 208.00 | 0.095 | 0.035 | 108.00 | 0.73 | 10 | 322-0200-1003 |

| 250 | 258.00 | 0.075 | 0.015 | 133.00 | 0.99 | 10 | 322-0250-1003 |

If the required dimensions are listed only as “production length”, the minimum order quantity is 150 m per order.

Positive and negative pressure values are recommended operational limits. Bending radius is measured on the inside of the hose bend. Subject to technical changes. All values determined at 20 °C and are approximate.