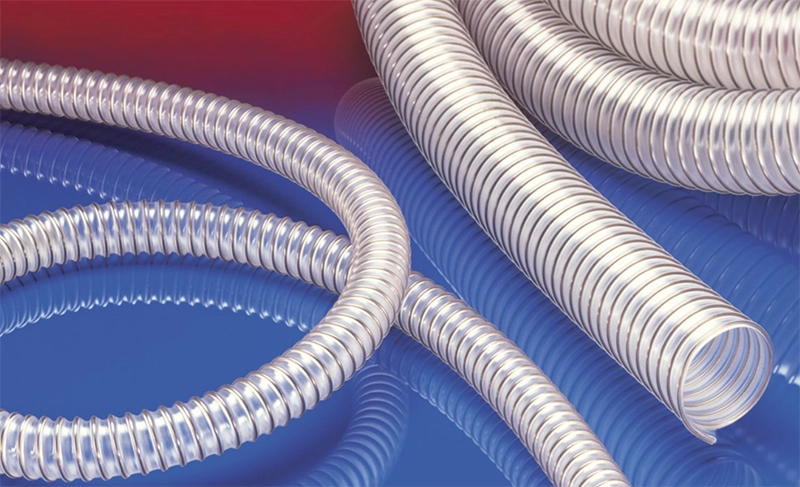

NORRES CP PVC 465 AS

Antistatic PVC hose for ATEX and ventilation – CP PVC 465 AS

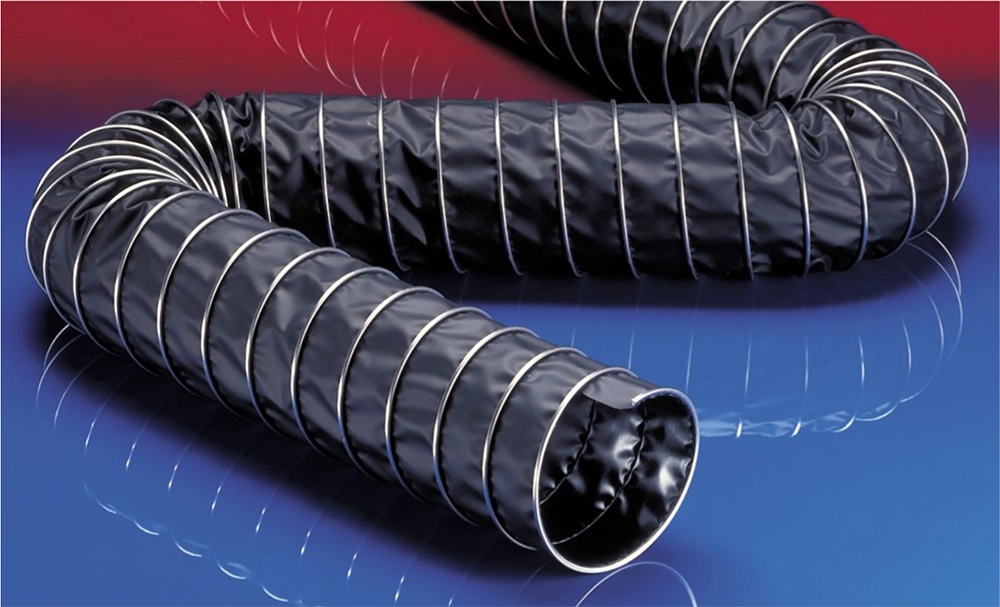

CP PVC 465 AS is a highly flexible, antistatic and chemical-resistant PVC ventilation hose for ATEX areas and industrial use. Built as a textile-reinforced clamp-profile hose with galvanised steel spiral, ideal for extraction, ventilation and handling of dust, vapours, fibres and light chemicals in potentially explosive atmospheres.

Flexible and durable for industrial duty

This hose combines high flexibility and compressibility with abrasion resistance thanks to the external steel reinforcement. It tolerates both cold and hot airstreams (−10 to +80 °C, short term up to +110 °C) and resists most chemicals, acids and alkalis. Perfect for welding fumes, chemical extraction, vapours or process air.

Safety in the ATEX zone

Thanks to its low surface resistance (typically ≤109 Ω), CP PVC 465 AS meets ATEX requirements and provides reliable dissipation of static charge during operation. Suitable for Zone 22 according to ATEX 2014/34/EU for ventilation/aspiration of combustible dust and vapours.

Need a flexible ATEX hose?

Contact us for technical advice and correct sizing of PVC hoses for ATEX and industrial ventilation.

Technical note

Construction: Textile-reinforced PVC with galvanised steel spiral. Antistatic wall and profile. RoHS and REACH compliant. Temperature: −10 °C to +80 °C (short term up to +110 °C).

FAQ: Antistatic PVC hose for ATEX and ventilation

Which environments is it used in?

Industrial ventilation, chemical process extraction, ATEX Zone 22 – where both flexibility and antistatic protection are required.

Is it chemical-resistant?

Yes, it resists many acids, alkalis and chemical vapours.

What temperature range does it handle?

Operating temperature −10 °C to +80 °C (short term up to +110 °C with air).

What does “AS” mean?

“AS” indicates antistatic properties designed for safe dissipation of static charges.

Related links

Technical specifications

| Inner diameter (mm) | Outer diameter (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Stock lengths (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 50–51 | 62.00 | 0.470 | 0.340 | 20.00 | 0.65 | 6 | 465-0050-1002 |

| 60 | 72.00 | 0.430 | 0.250 | 22.00 | 0.75 | 6 | 465-0060-1002 |

| 63–65 | 77.00 | 0.410 | 0.230 | 24.00 | 0.81 | 6 | 465-0065-1002 |

| 75–76 | 87.00 | 0.380 | 0.180 | 26.00 | 0.91 | 6 | 465-0075-1002 |

| 80 | 92.00 | 0.370 | 0.160 | 26.00 | 0.97 | 6 | 465-0080-1002 |

| 89–90 | 102.00 | 0.345 | 0.110 | 28.00 | 1.07 | 6 | 465-0090-1002 |

| 100–102 | 112.00 | 0.210 | 0.100 | 31.00 | 0.87 | 6 | 465-0100-1002 |

| 110 | 122.00 | 0.200 | 0.085 | 33.00 | 0.95 | 6 | 465-0110-1002 |

| 114–115 | 127.00 | 0.195 | 0.080 | 35.00 | 0.99 | 6 | 465-0115-1002 |

| 120 | 132.00 | 0.190 | 0.075 | 35.00 | 1.03 | 6 | 465-0120-1002 |

| 125–127 | 137.00 | 0.180 | 0.070 | 37.00 | 1.05 | 6 | 465-0125-1002 |

| 150–152 | 162.00 | 0.140 | 0.040 | 41.00 | 0.84 | 6 | 465-0150-1002 |

| 160 | 172.00 | 0.135 | 0.035 | 43.00 | 0.89 | 6 | 465-0160-1002 |

| 170 | 182.00 | 0.130 | 0.035 | 45.00 | 0.94 | 6 | 465-0170-1002 |

| 178–180 | 192.00 | 0.125 | 0.030 | 47.00 | 0.99 | 6 | 465-0180-1002 |

| 200–203 | 212.00 | 0.105 | 0.025 | 51.00 | 0.85 | 6 | 465-0200-1002 |

| 215 | 227.00 | 0.100 | 0.020 | 55.00 | 0.91 | 6 | 465-0215-1002 |

| 225 | 237.00 | 0.095 | 0.020 | 57.00 | 0.94 | 6 | 465-0225-1002 |

| 250 | 262.00 | 0.075 | 0.020 | 61.00 | 1.04 | 6 | 465-0250-1002 |

| 305 | 317.00 | 0.065 | 0.010 | 72.00 | 1.26 | 6 | 465-0305-1002 |

If the required dimensions are listed only as “production length”, the minimum order quantity is 150 metres per order.

Positive and negative pressure values are recommended operating limits. Bending radius is measured on the inside of the hose bend. Subject to technical changes. All values determined at 20 °C and are approximate.