NORRES AIRDUC® PUR 355 EC (HD)

Electrically conductive PUR hose for ATEX Zones 20–22

An electrically conductive PUR hose for ATEX Zones 20–22 is essential for safe conveying, extraction and handling of dust, powders and granulates in potentially explosive atmospheres. NORRES AIRDUC® PUR 355 EC (HD) is developed specifically for ATEX-classified areas and ensures correct operation in Zones 20, 21 and 22. Read more about ATEX, zone classification and safety.

Heavy-duty ATEX hose for high flow

NORRES AIRDUC® PUR 355 EC (HD) is an electrically conductive PUR hose designed for ATEX Zones 20–22 and similar risk environments. This robust polyurethane hose enables safe conveying and extraction of dust and granulates — combining abrasion resistance, flexibility and pressure/vacuum strength. It is ideal for process plants, industrial vacuums and systems that require a conductive, ATEX-certified hose.

Static electricity and grounding are critical in ATEX areas. See our guide: Know your Ohm, know your ATEX risk.

Proven safety in Ex areas

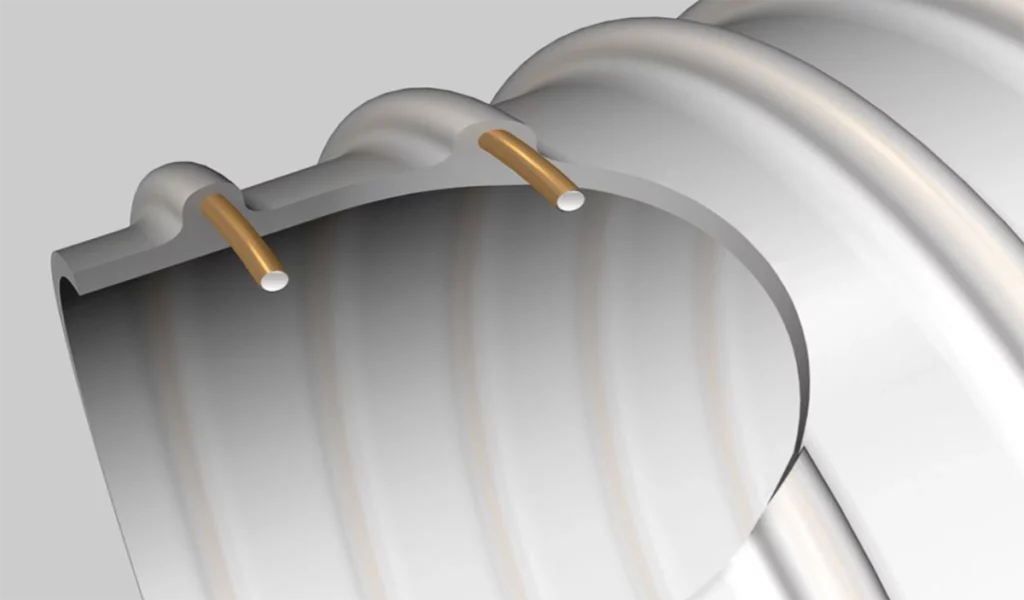

AIRDUC® 355 EC (HD) features a conductive Pre-PUR® wall with integrated spring steel wire and a low surface resistance (< 103 Ω). The hose is DEKRA tested, EC-marked according to TRGS 727 and ATEX 2014/34/EU and can be grounded as part of an Ex system. The construction prevents charge build-up and ensures permanent conductivity throughout the hose wall. Learn more about how weak links can create explosion hazards.

Flexible performance and temperature resistance

The design provides low weight, high vacuum/pressure resistance and a temperature range from –40 °C to +90 °C. The hose remains flexible at low temperatures and resists oil, petrol and most chemicals. This electrically conductive PUR hose for ATEX Zones 20–22 is therefore optimal for process plants, dust extraction and transport of dry bulk materials in hazardous areas.

Need technical advice?

Contact us for guidance on selecting electrically conductive PUR hoses for ATEX Zones 20–22, plus couplings and grounding. We help with sizing and system compatibility.

Technical note

TRGS 727 requires electrically conductive material (< 106 Ω) for pneumatic transport of combustible dust. AIRDUC® 355 EC (HD) fulfils this requirement — suitable for Zone 20 inside the hose and Zones 21/22 outside. The hose is made of conductive Pre-PUR® with spring steel wire, ensuring effective grounding and dissipation of static charges.

FAQ: Conductive PUR hose for ATEX Zones 20–22

Which environments is it suitable for?

Process plants, industrial vacuum systems and areas with dust, granulates and gases.

Is it tested according to ATEX?

Yes — tested and approved to ATEX 2014/34/EU and TRGS 727 for dust Zones 21 and 22 and internally for Zone 20.

Can it be grounded?

Yes — the spiral wire can be connected to earth and the hose wall is conductive for full ESD safety.

Is it food approved?

No — AIRDUC® 355 EC (HD) is not for food contact; only for industrial products and process waste.

Related links

Technical specifications

| Inner diameter (inch / mm) | Outer diameter (mm) | Pressure DIN 26057 (50% elongation) (bar) | Vacuum DIN 26057 (axially fixed) (bar) | Bending radius (mm) | Weight (kg/m) | Stock lengths (m) | Production lengths (m) | Order no. |

|---|---|---|---|---|---|---|---|---|

| 1 / 25 | 32.00 | 2.930 (4.47) | 1.000 (1.00) | 20.00 | 0.28 | 10 | 15 | 355-0025-1003 |

| - / 30 | 40.00 | 2.470 (3.99) | 1.000 (1.00) | 25.00 | 0.47 | 10 | 15 | 355-0030-1003 |

| 1.25 / 32 | 42.00 | 2.325 (3.75) | 0.950 (1.00) | 26.00 | 0.47 | - | 10 | 355-0032-1003 |

| 1.5 / 38 | 48.00 | 1.975 (3.19) | 0.915 (1.00) | 29.00 | 0.55 | 10 | - | 355-0038-1003 |

| - / 40 | 50.00 | 1.880 (3.03) | 0.905 (1.00) | 30.00 | 0.57 | 10 | 15 | 355-0040-1003 |

| 2 / 50–51 | 60.00 | 1.515 (2.45) | 0.783 (1.00) | 35.00 | 0.71 | 10 15 20 | - | 355-0050-1003 |

| - / 55 | 65.00 | 1.385 (2.23) | 0.712 (1.00) | 38.00 | 0.77 | - | 10 | 355-0055-1003 |

| 2.36 / 60 | 70.00 | 1.270 (2.05) | 0.650 (1.00) | 40.00 | 0.83 | 10 | 15 20 | 355-0060-1003 |

| 2.5 / 63–65 | 75.00 | 1.175 (1.90) | 0.603 (1.00) | 43.00 | 0.89 | 10 | 15 | 355-0065-1003 |

| - / 70 | 81.00 | 1.515 (2.45) | 0.513 (1.00) | 46.00 | 1.01 | 10 15 | - | 355-0070-1003 |

| 3 / 75–76 | 86.00 | 1.420 (2.29) | 0.479 (1.00) | 66.00 | 1.07 | - | 10 | 355-0075-1003 |

| - / 80 | 91.00 | 1.335 (2.15) | 0.451 (1.00) | 69.00 | 1.14 | 10 | - | 355-0080-1003 |

| 4 / 100 | 111.00 | 1.075 (1.73) | 0.370 (0.94) | 73.00 | 1.41 | 10 15 | - | 355-0100-1003 |

| - / 110 | 121.00 | 0.980 (1.58) | 0.320 (0.77) | 90.00 | 1.54 | 10 | - | 355-0110-1003 |

| 4.5 / 114–115 | 126.00 | 0.935 (1.51) | 0.323 (0.70) | 94.00 | 1.61 | 15 | 10 | 355-0115-1003 |

| 5 / 125–127 | 136.00 | 0.865 (1.39) | 0.290 (0.57) | 100.00 | 1.74 | 10 | - | 355-0125-1003 |

| 8 / 200 | 212.00 | 0.505 (0.81) | 0.142 (0.34) | 226.00 | 2.85 | 10 | - | 355-0200-1003 |

| - / 300 | 313.00 | 0.340 (0.54) | 0.085 (0.19) | 226.00 | 4.32 | 10 | - | 355-0300-1003 |