NORRES PROTAPE® TPE 320 AS (XLD)

Antistatic TPE hose for hot and cold gases

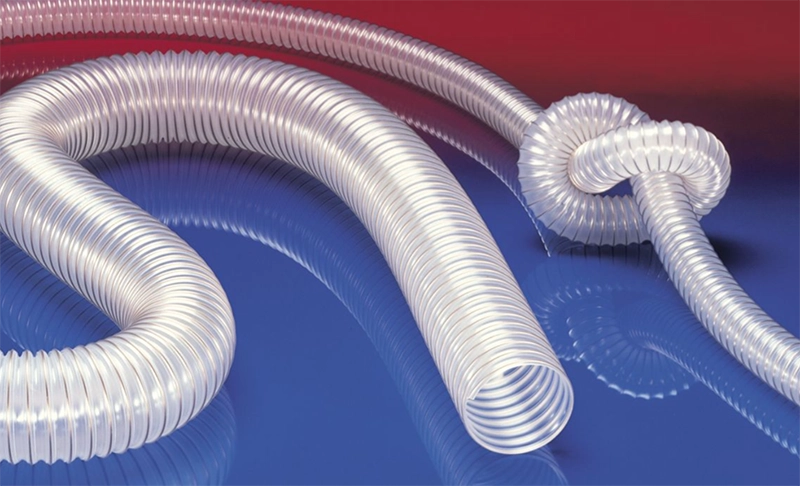

NORRES PROTAPE® TPE 320 AS (XLD) is a lightweight and highly flexible thermoplastic rubber (TPE) hose designed for the transport and extraction of hot or cold gases, dust and fibres. It is ideal for demanding ventilation, drying and heating applications where low weight and temperature resistance are essential – for example in plastic dryers, extrusion systems, textile and printing machinery, bus and marine ventilation, or hot-air supply systems.

Performance and applications

The hose withstands temperatures from −40 °C to +125 °C (short-term up to +150 °C) and is resistant to oil, fuel, chemicals, acids and alkalis. Suitable for hot and cold air systems, extraction of dust and light particles, and process ventilation in ATEX zone 22. The wall is permanently antistatic according to ISO 8031 with surface resistance of approx. 10⁹ Ω.

Certifications and construction

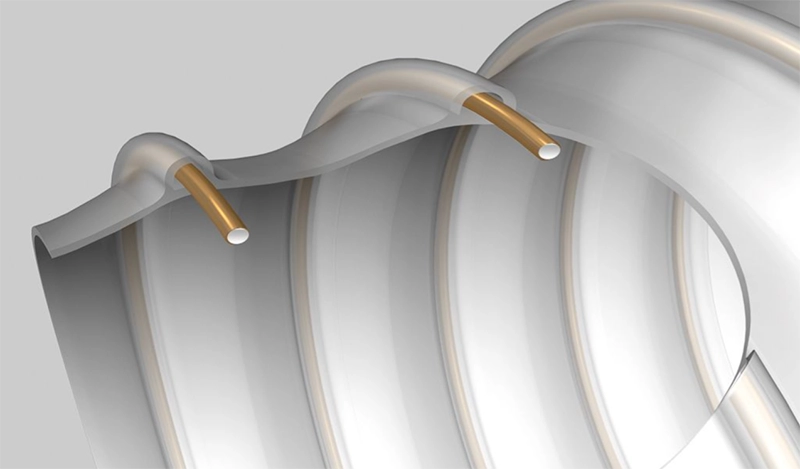

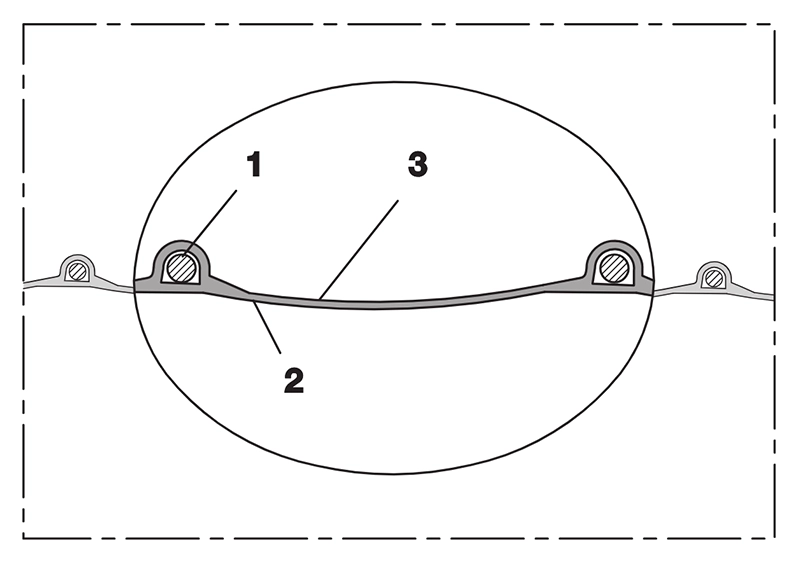

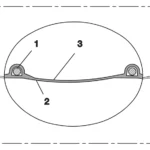

PROTAPE® TPE 320 AS (XLD) is a tape hose with built-in spring steel wire (1), antistatic TPE wall (2) and outer layer (3) made of flexible thermoplastic rubber.

Complies with RoHS, REACH and ISO 8031. Its excellent flexibility, low weight and high compressibility make it easy to handle even in confined or mobile installations.

Need technical guidance on ATEX hoses?

Contact us for assistance with hose selection, dimensioning and safe integration of antistatic hoses for ventilation, hot-air or ATEX zone 22 applications.

FAQ: PROTAPE® TPE 320 AS (XLD)

What is the hose used for?

For conveying and extraction of hot or cold gases, dust, fibres and light particles in ventilation or process systems.

How does TPE differ from PUR?

TPE offers higher temperature resistance (up to 150 °C) and better flexibility at low temperatures, while PUR is generally more abrasion-resistant.

Is it antistatic?

Yes – the wall is permanently antistatic according to ISO 8031 with a surface resistance of approx. 10⁹ Ω, suitable for zone 22.

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 50–51 | 58.0 | 0.24 | 0.11 | 33 | 0.23 | 10 | 320-0050-0000 |

| 60 | 68.0 | 0.20 | 0.09 | 38 | 0.26 | 10 | 320-0060-0000 |

| 75–76 | 83.0 | 0.16 | 0.07 | 46 | 0.33 | 10 | 320-0075-0000 |

| 100–102 | 109.0 | 0.12 | 0.06 | 58 | 0.52 | 10 | 320-0100-0000 |

| 125–127 | 134.0 | 0.10 | 0.05 | 71 | 0.64 | 10 | 320-0125-0000 |

| 150–152 | 159.0 | 0.08 | 0.03 | 83 | 0.76 | 10 | 320-0150-0000 |

| 200–203 | 210.0 | 0.06 | 0.02 | 108 | 1.01 | 10 | 320-0200-0000 |

| 250 | 258.0 | 0.05 | 0.02 | 133 | 1.21 | 10 | 320-0250-0000 |

Overpressure and underpressure are recommended threshold operating values. The bending radius is measured through the inside of the hose arch. Subject to technical modifications. All values determined at 20 °C and approximate.