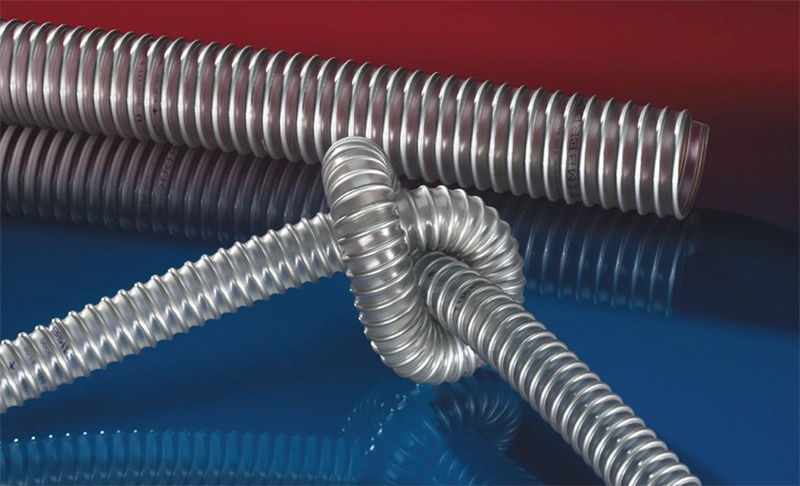

NORRES PROTAPE® PUR-INOX 330 FOOD-AS (LD)

Antistatic food-grade and pharmaceutical PUR hose with stainless steel spiral

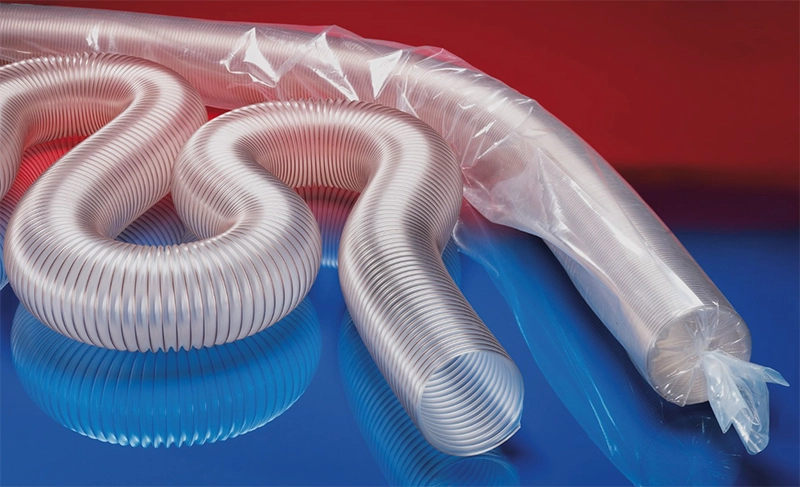

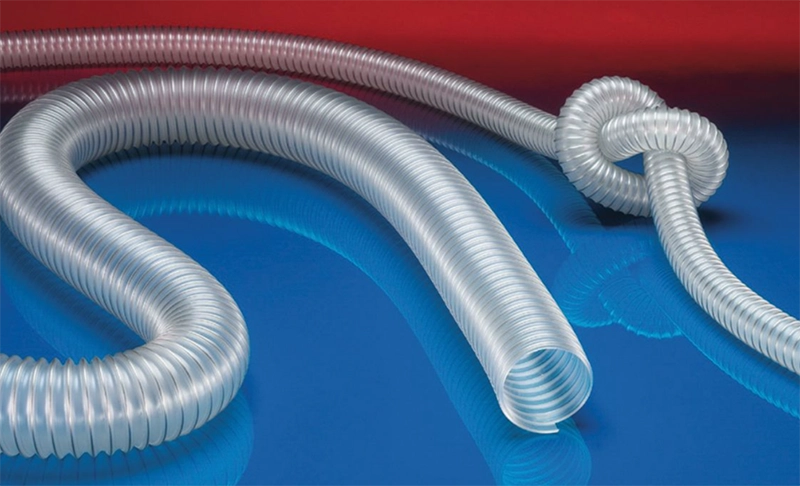

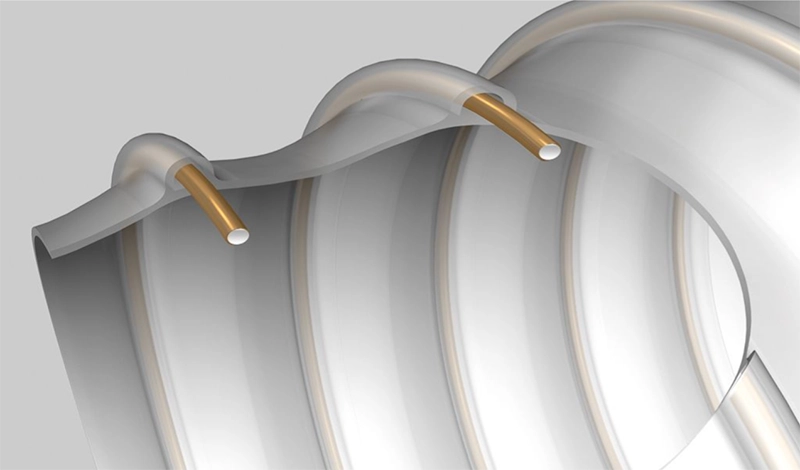

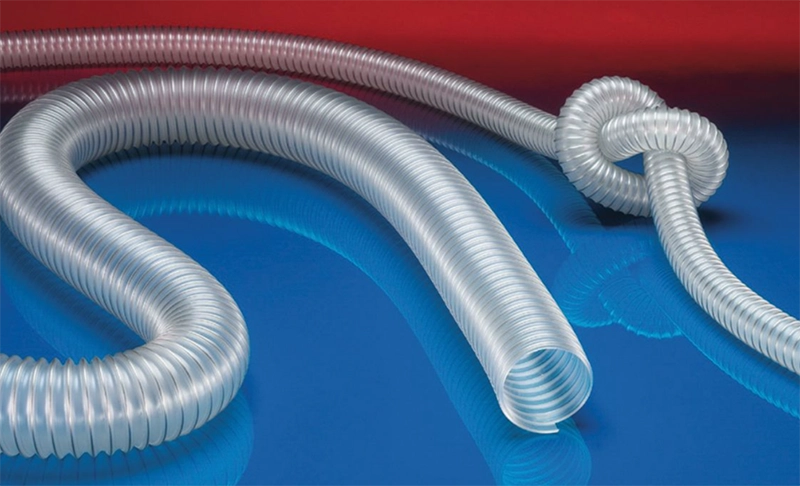

NORRES PROTAPE® PUR-INOX 330 FOOD-AS (LD) is a lightweight, flexible and antistatic polyurethane hose with a built-in stainless steel spiral (INOX). It is designed for the safe transport of dry foodstuffs, granulates, powders, grains and pharmaceutical products in environments requiring hygiene, conductivity and ATEX compliance.

Performance and applications

The hose is suitable for pneumatic conveying systems, silos, filling equipment, mills, dryers and packaging machines, as well as for the transport of rice, sugar, coffee, tea, flour, cereals and milk or plant-based powders.

It is highly flexible, compressible (3:1), abrasion-resistant and lightweight with excellent chemical resistance and low-temperature flexibility (−40 °C).

Approved for ATEX zones 20–22 (inside) and 0–2 (for gases and liquids).

Certifications and construction

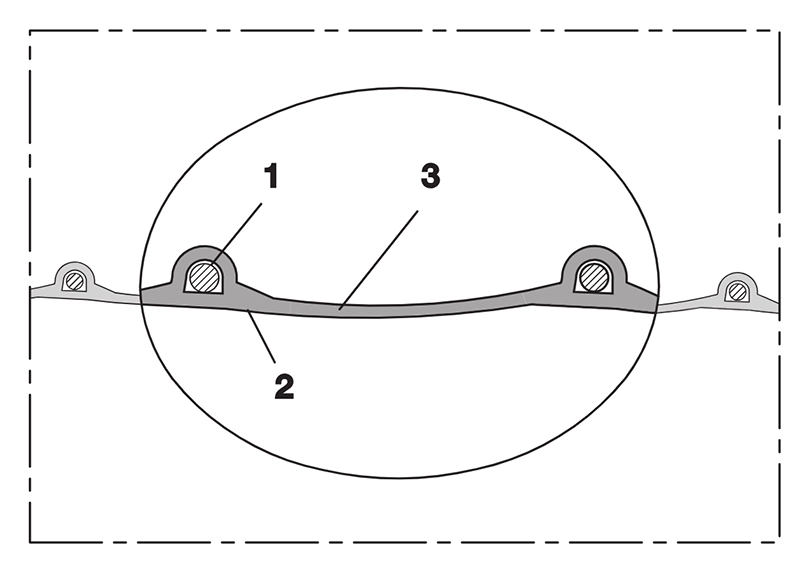

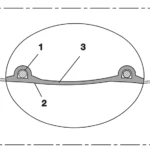

PROTAPE® PUR-INOX 330 FOOD-AS (LD) is a tape hose with stainless steel spring wire (1), antistatic PUR wall (2) and outer layer (3) made of ether-based Pre-PUR®.

The complete hose is tested and certified according to EU 10/2011, EC 1935/2004, EU 2015/174 and FDA 21 CFR 177.2600.

Manufactured in compliance with GMP EC 2023/2006.

Electrical resistance < 10⁹ Ω (TRGS 727 < 2.5 × 10⁸ Ω·m). Complies with ATEX 2014/34/EU, TRGS 727, RoHS and REACH.

Need technical guidance on food-grade and ATEX hoses?

Contact us for professional advice on selecting conductive hoses for the safe transport of powders, granulates and food products in ATEX zones.

FAQ: NORRES PROTAPE® PUR-INOX 330 FOOD-AS (LD)

Is the hose food-grade approved?

Yes – the complete hose is certified according to EU 10/2011, EC 1935/2004 and FDA 21 CFR 177.2600.

Which ATEX zones is it suitable for?

Zones 20, 21 and 22 (for dust/powder inside) and zones 0–2 (for gases and liquids).

What does INOX mean?

INOX refers to the use of stainless steel spring wire in the hose wall, providing increased hygiene and corrosion resistance.

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 38 | 45.0 | 1.08 | 0.36 | 26 | 0.22 | 10 | 330-0038-1018 |

| 50–51 | 58.0 | 0.82 | 0.22 | 33 | 0.38 | 10 | 330-0050-1018 |

| 75–76 | 83.0 | 0.55 | 0.15 | 46 | 0.55 | 10 | 330-0075-1018 |

| 100–102 | 108.0 | 0.42 | 0.08 | 58 | 0.69 | 10 | 330-0100-1018 |

| 125–127 | 133.0 | 0.34 | 0.07 | 71 | 0.85 | 10 | 330-0125-1018 |

| 150–152 | 158.0 | 0.28 | 0.06 | 83 | 1.01 | 10 | 330-0150-1018 |

| 160 | 168.0 | 0.26 | 0.05 | 88 | 1.07 | 10 | 330-0160-1018 |

| 200–203 | 208.0 | 0.21 | 0.03 | 108 | 1.35 | 10 | 330-0200-1018 |

| 250 | 258.0 | 0.17 | 0.03 | 133 | 1.67 | 10 | 330-0250-1018 |

Overpressure and underpressure are recommended threshold operating values. The bending radius is measured through the inside of the hose arch. Subject to technical modifications. All values determined at 20 °C and approximate.