NORRES PROTAPE® PUR 333 AS (MD)

Antistatic PUR hose for dust, granulate and process extraction

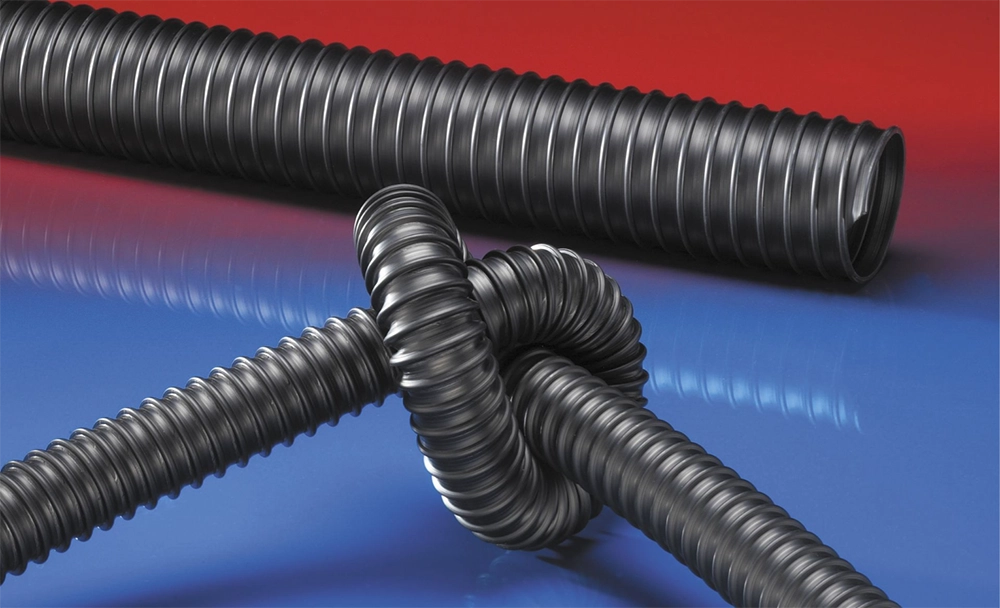

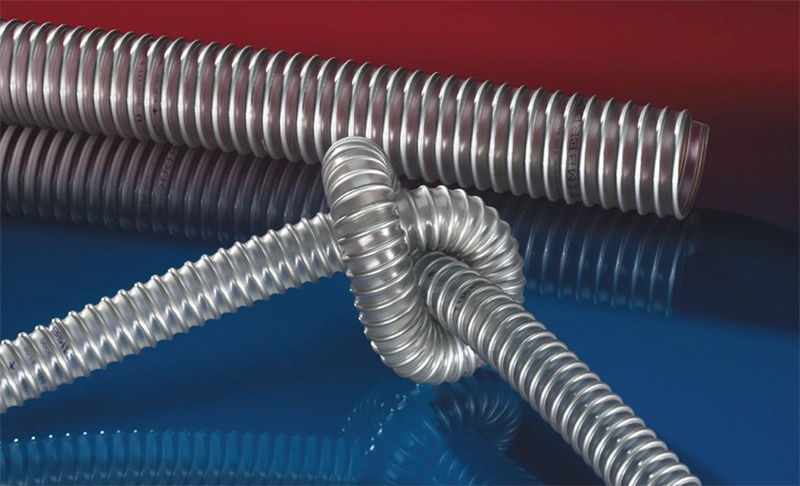

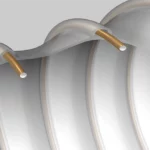

NORRES PROTAPE® PUR 333 AS (MD) is a medium-duty, electrically conductive polyurethane hose designed for the transport and extraction of dust, powder, granulates and gases in industrial environments with risk of static discharge. It combines high abrasion resistance, chemical durability and flexibility – ideal for ATEX zones and pneumatic conveying systems.

Performance and applications

The hose is used in process systems, filter units, silos, vacuum conveying and granulate handling. It is resistant to oil, fuel and many solvents and remains flexible at temperatures down to −40 °C.

Antistatic according to ISO 8031 and TRGS 727 with electrical resistance < 10⁹ Ω. Suitable for ATEX zone 22 (dust/powder inside) and zones 1/2 (gases and liquids).

Temperature range: −40 °C to +90 °C (short-term up to +125 °C).

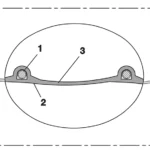

Certifications and construction

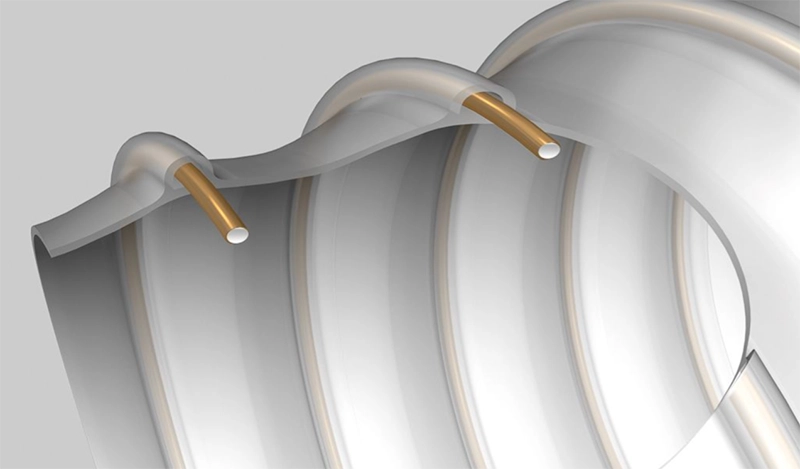

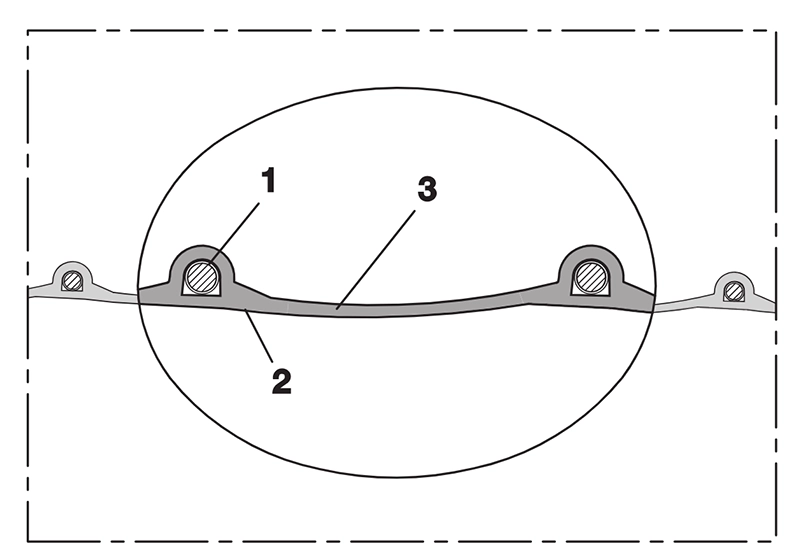

PROTAPE® PUR 333 AS (MD) is a tape hose with built-in spring steel wire (1), antistatic PUR wall (2) and outer layer (3) made of premium ester-based polyurethane (Pre-PUR®).

Complies with ATEX 2014/34/EU, TRGS 727, RoHS, REACH and ISO 8031.

Characterised by a medium wall thickness (approx. 0.7 mm) and high operational reliability under vacuum or pressure.

Need technical guidance on ATEX hoses?

Contact us for professional support in selecting conductive hoses for dust, granulate and process extraction in ATEX environments.

FAQ: NORRES PROTAPE® PUR 333 AS (MD)

What is the hose used for?

For extraction and transport of dust, granulate and light abrasive materials in ATEX areas and industrial process installations.

How does the 333 AS (MD) differ from the 330 AS (LD)?

The 333 AS (MD) version has a thicker wall (0.7 mm) for greater durability and longer service life while maintaining low weight and high flexibility.

Is it suitable for ATEX installations?

Yes – it is permanently antistatic (resistance < 10⁹ Ω) and approved for zone 22 (dust/powder) as well as zones 1/2 (gases and liquids).

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 38 | 46.0 | 1.12 | 0.42 | 26 | 0.28 | 10 | 333-0038-1005 |

| 50–51 | 59.0 | 0.91 | 0.25 | 33 | 0.41 | 10 | 333-0050-1005 |

| 65 | 74.0 | 0.70 | 0.17 | 42 | 0.54 | 10 | 333-0065-1005 |

| 75–76 | 84.0 | 0.60 | 0.14 | 48 | 0.62 | 10 | 333-0075-1005 |

| 80 | 89.0 | 0.55 | 0.13 | 50 | 0.67 | 10 | 333-0080-1005 |

| 100–102 | 111.0 | 0.43 | 0.08 | 63 | 0.83 | 10 | 333-0100-1005 |

| 125–127 | 136.0 | 0.35 | 0.06 | 78 | 1.00 | 10 | 333-0125-1005 |

| 150–152 | 161.0 | 0.30 | 0.05 | 91 | 1.15 | 10 | 333-0150-1005 |

| 160 | 171.0 | 0.28 | 0.04 | 96 | 1.23 | 10 | 333-0160-1005 |

| 200–203 | 212.0 | 0.22 | 0.03 | 116 | 1.56 | 10 | 333-0200-1005 |

Overpressure and underpressure are recommended threshold operating values. The bending radius is measured through the inside of the hose arch. Subject to technical modifications. All values determined at 20 °C and approximate.