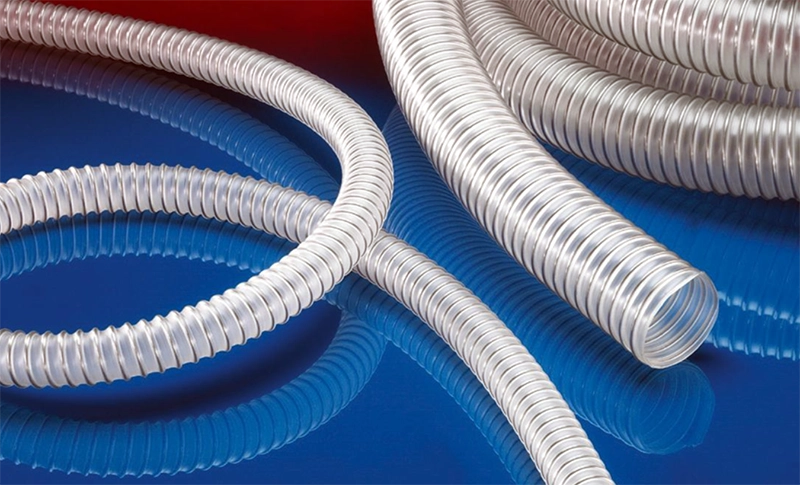

NORRES AIRDUC® PUR-INOX 355 FOOD-AS (HD)

Antistatic food-grade PUR hose with stainless steel spiral – heavy duty

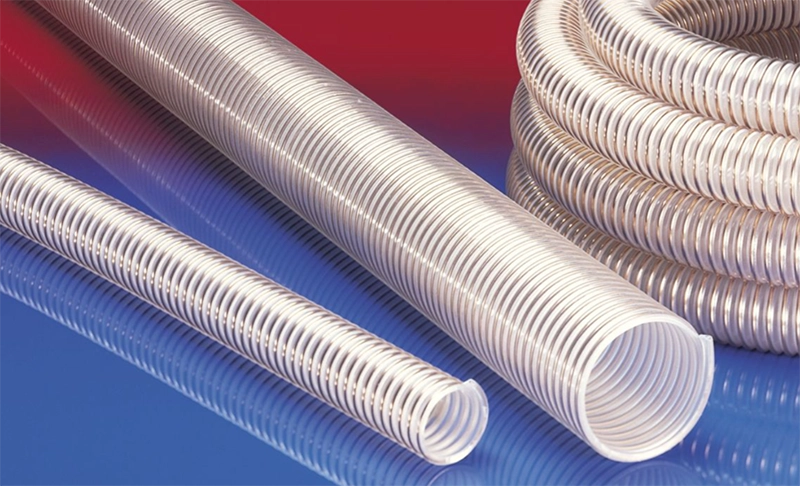

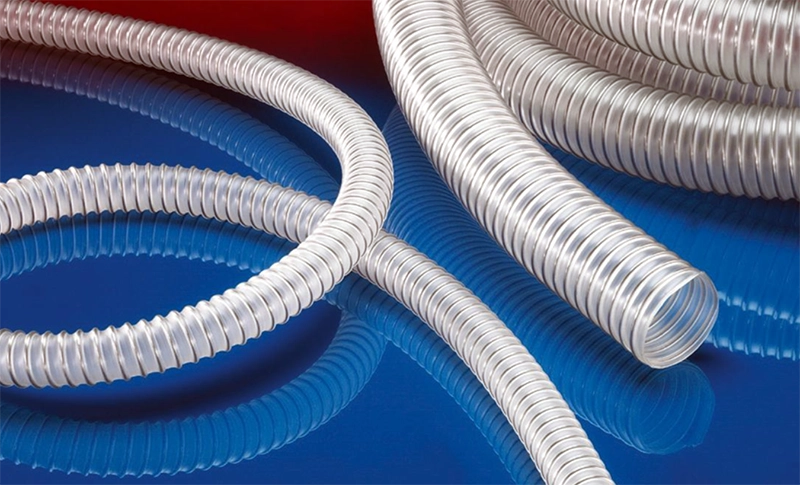

The NORRES AIRDUC® PUR-INOX 355 FOOD-AS (HD) is a heavy-duty, permanently antistatic hose made of premium ether-polyurethane (Pre-PUR®) with an embedded stainless steel spring spiral (INOX). It is designed for conveying dry food products, powders, granulates and gases in demanding environments including food-industry and pharmaceutical applications, as well as explosion-hazard zones. :contentReference[oaicite:2]{index=2}

Applications

Ideal for use in the food and pharmaceutical industries: vacuum conveying, dosing systems, big-bag discharge, mixers, dryers, packaging machines, and transport of rice, cereals, sugar, milk powder, coffee, tea and flour. Also suitable for high-throughput abrasion applications in explosion hazard zones (Zone 20/21/22 inside). :contentReference[oaicite:3]{index=3}

Features and approvals

- Heavy-duty construction with high abrasion resistance. :contentReference[oaicite:4]{index=4}

- Permanently antistatic wall: <10⁹ Ω in accordance with ISO 8031, (according to TRGS 727 <2.5 × 10⁸ Ω·m). :contentReference[oaicite:5]{index=5}

- Food-grade polyurethane hose — complies with EU 10/2011, EC 1935/2004, EU 2015/174 and FDA 21 CFR 177.2600. :contentReference[oaicite:6]{index=6}

- Good resistance to oil, gasoline and chemicals; excellent low-temperature flexibility. :contentReference[oaicite:7]{index=7}

- Temperature range: −40 °C to +90 °C (short term up to +125 °C). :contentReference[oaicite:8]{index=8}

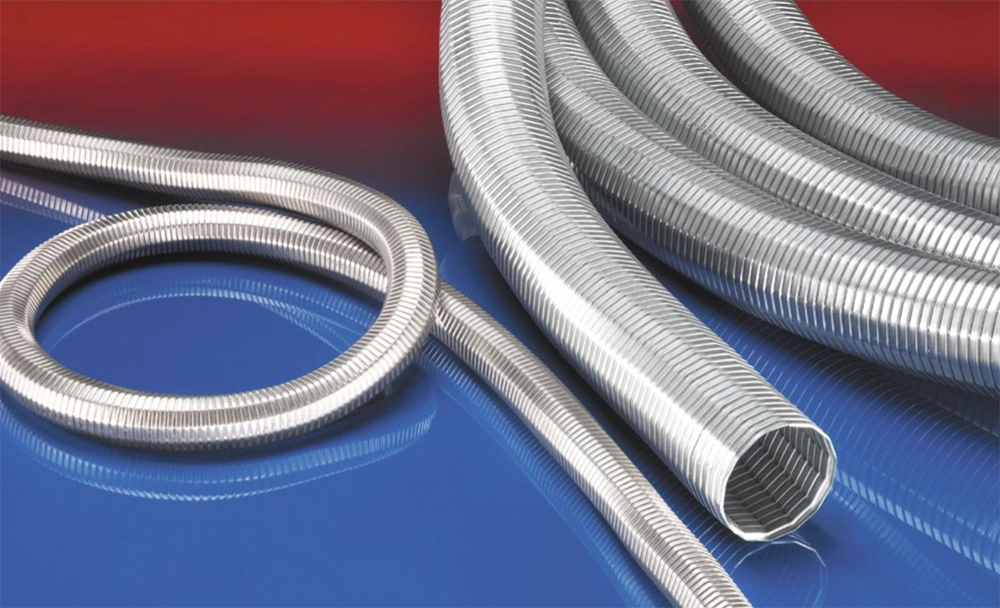

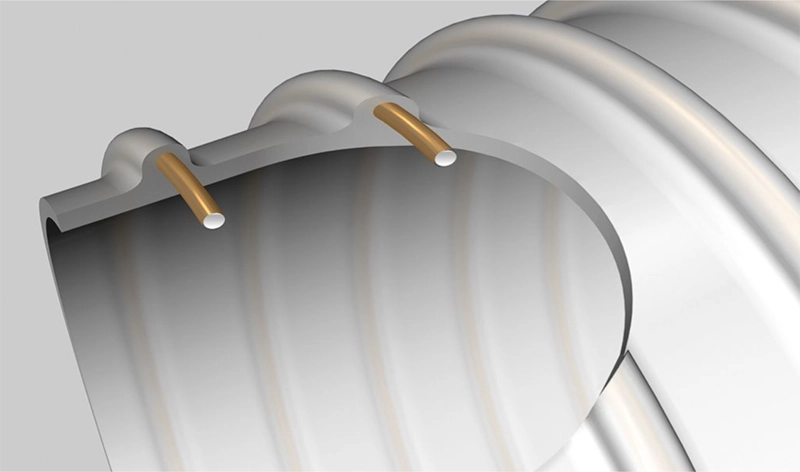

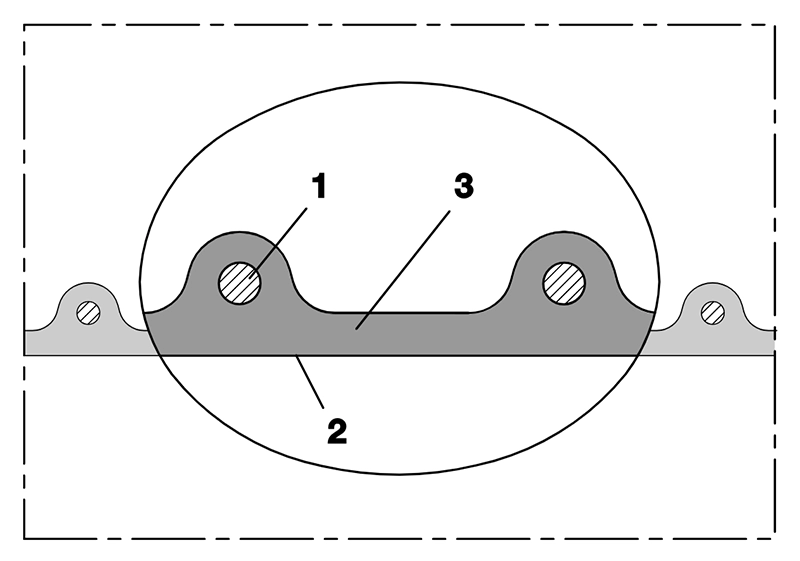

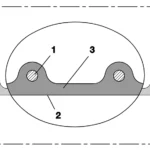

Construction

1 = Stainless steel spring wire (INOX) embedded in the wall

2 = Permanently antistatic ether-PUR (Pre-PUR®) wall

3 = AIRDUC® profile with smooth inner and outer surfaces for optimal flow and easy cleaning. :contentReference[oaicite:9]{index=9}

Recommended accessories

- CLAMP 210 / 212 – stainless steel hose clamps with grounding option

- CONNECT 228 – transition/adapter couplings

- CONNECT 270-271 – hygienic stainless steel couplings

- CONNECT 245 FOOD – Tri-Clamp stainless steel connection

Contact us for professional advice on correct installation, grounding and ATEX-compliant connection.

Need technical assistance?

Contact us for professional guidance on the selection, installation and integration of flexible antistatic food-grade hoses in process and conveying systems.

FAQ: NORRES AIRDUC® PUR-INOX 355 FOOD-AS (HD)

What is this hose used for?

For the vacuum or pneumatic conveying of dry food, powders and granulates in food and pharmaceutical processes, including big-bag discharge and mixers.

Is the hose antistatic?

Yes — it features a permanently antistatic wall (<10⁹ Ω) in accordance with ISO 8031 and complies with TRGS 727 for zones 20, 21, 22 (dust). :contentReference[oaicite:10]{index=10}

Is it food-grade certified?

Yes — the hose is certified to EU 10/2011, EC 1935/2004, EU 2015/174 and FDA 21 CFR 177.2600. :contentReference[oaicite:11]{index=11}

What are the operating temperature and pressure ranges?

Operating temperature from −40 °C to +90 °C (short term up to ~+125 °C). Pressure and vacuum specifications depend on diameter — please refer to the official data sheet. :contentReference[oaicite:12]{index=12}

Which accessories are recommended for correct installation?

Use certified clamps and couplings such as CLAMP 210/212 with grounding, CONNECT 228 and CONNECT 270-271 for hygienic and antistatic installations. Always ensure proper grounding and ATEX-compliant connections.

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Order No. |

|---|---|---|---|---|---|---|

| 25 | 32.00 | 3.565 | 1.000 | 20.00 | 0.28 | 355-0025-1018 |

| 32 | 42.00 | 3.490 | 1.000 | 26.00 | 0.44 | 355-0032-1018 |

| 38 | 48.00 | 2.975 | 0.985 | 29.00 | 0.52 | 355-0038-1018 |

| 40 | 50.00 | 2.835 | 0.935 | 30.00 | 0.54 | 355-0040-1018 |

| 50-51 | 60.00 | 2.300 | 0.750 | 35.00 | 0.66 | 355-0050-1018 |

| 55 | 65.00 | 2.100 | 0.680 | 38.00 | 0.72 | 355-0055-1018 |

| 60 | 70.00 | 1.930 | 0.625 | 40.00 | 0.78 | 355-0060-1018 |

| 63-65 | 75.00 | 1.790 | 0.575 | 43.00 | 0.84 | 355-0065-1018 |

| 70 | 81.00 | 1.665 | 0.505 | 62.00 | 0.98 | 355-0070-1018 |

| 75-76 | 86.00 | 1.560 | 0.475 | 66.00 | 1.05 | 355-0075-1018 |

| 80 | 91.00 | 1.465 | 0.450 | 69.00 | 1.11 | 355-0080-1018 |

| 89-90 | 101.00 | 1.305 | 0.395 | 76.00 | 1.30 | 355-0090-1018 |

| 100-102 | 111.00 | 1.180 | 0.385 | 83.00 | 1.49 | 355-0100-1018 |

| 125-127 | 136.00 | 0.950 | 0.305 | 101.00 | 1.84 | 355-0125-1018 |

| 150-152 | 161.00 | 0.795 | 0.285 | 118.00 | 2.41 | 355-0150-1018 |

| 160 | 172.00 | 0.745 | 0.265 | 125.00 | 2.56 | 355-0160-1018 |

| 178-180 | 191.00 | 0.665 | 0.235 | 139.00 | 2.90 | 355-0180-1018 |

| 200-203 | 213.00 | 0.600 | 0.145 | 156.00 | 3.12 | 355-0200-1018 |

Positive and negative pressures are recommended operating limits. Bending radius measured inside the curve. Subject to technical changes. All values at approx. 20 °C. :contentReference[oaicite:13]{index=13}