NORRES TIMBERDUC® PUR 531 AS (XLD)

Antistatic and flame-retardant lightweight PUR hose for the woodworking and furniture industry – extra light duty

NORRES TIMBERDUC® PUR 531 AS (XLD) is an ultra-light, highly flexible, antistatic, and flame-retardant suction and transport hose ideal for wood dust and chip extraction in fast-moving CNC systems and furniture production. The hose can be compressed 3:1, offers good abrasion resistance, chemical resistance, and features a very smooth inner wall for efficient airflow at high machine speeds.

Applications

The hose is typically used for:

- Extraction of wood dust and chips in CNC machines and fast-processing lines

- Dedusting and filter systems in woodworking and furniture manufacturing

- Extraction in systems requiring low hose weight and maximum flexibility

- Oil mist extraction and pneumatic transport systems

- Explosion hazardous areas with combustible dust (Zone 22)

Technical note: The hose is suitable when material (dust, chips) transported inside may be classified as ATEX zone 20, 21, or 22 inside the hose (the material flow). External ATEX zone classification is determined separately in the facility’s risk assessment.

Properties and Approvals

- Ultra-light, highly flexible – easy to install on moving machine parts

- Compressible (3:1) for convenient storage and transport

- Permanently antistatic wall – surface resistance < 10⁹ Ω according to ISO 8031 (TRGS 727, NFPA 652)

- Flame-retardant according to DIN 4102-B1

- Excellent resistance to oil, gasoline and chemicals; microbe-resistant

- Temperature range: −40 °C to +90 °C (short-term up to +125 °C)

- Complies with ATEX 2014/34/EU and TRGS 727 for pneumatic systems with combustible dust

- Complies with DIN 26057 Type 1

- RoHS and REACH compliant

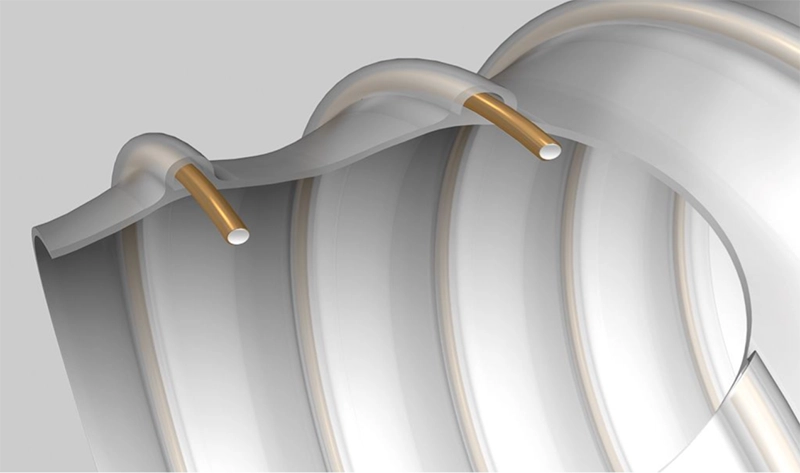

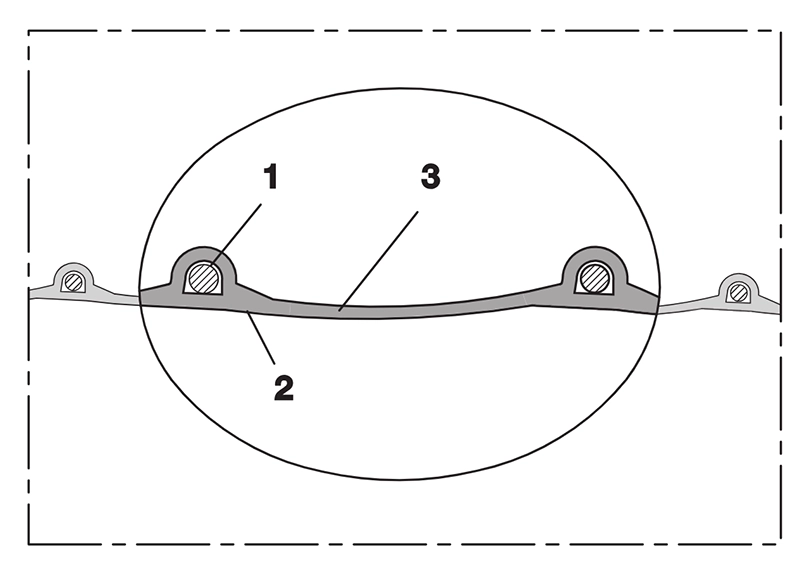

Construction

1 = Spring steel wire permanently embedded in the wall

2 = Wall of permanently antistatic premium polyurethane (Pre-PUR®), resistant to aggressive wood types and preservatives

3 = PROTAPE® profile with a smooth interior for low friction and easy cleaning

Wall thickness approx. 0.4 mm. Further lengths and diameters available on request.

Technical Note

In the woodworking industry, ATEX requirements are combined with industry practice: zone classification typically follows EN 60079-10-2 and TRGS 727 (electrostatics). For lightweight hoses, DIN 26057 Type 1 and BG guidelines for extraction systems are standard. TIMBERDUC® 531 AS (XLD) meets these requirements with permanent antistatic walls, flame retardancy, and mechanical lightness.

Recommended Accessories

- CLAMP 210 / 212 / 213 / 217 – hose clamps with equipotential bonding

- CONNECT 223 / 228 / 270–271 – adapters and molded couplings

Need technical assistance?

Contact us for advice on correct hose selection, assembly, equipotential bonding, and ATEX compliant integration in your extraction and filtration systems.

FAQ: NORRES TIMBERDUC® PUR 531 AS (XLD)

What is this hose used for?

For extracting wood dust and chips in lightweight, fast-moving systems (especially CNC), where low hose weight and high flexibility are required.

How does it relate to ATEX?

The hose is suitable when the material flow inside may pose an explosion hazard (classified as ATEX zone 20/21/22 inside the hose).

Is the hose antistatic and flame-retardant?

Yes. Permanently antistatic wall (< 10⁹ Ω, ISO 8031 / TRGS 727 / NFPA 652) and flame-retardant according to DIN 4102-B1.

What are the temperature and pressure/vacuum limits?

Temperature −40 °C to +90 °C (short-term +125 °C). Pressure and vacuum values depend on diameter (see technical table).

Which accessories are recommended?

CLAMP 210/212/213/217 and CONNECT 223/228/270–271, depending on equipment and equipotential bonding needs.

Related Links

Technical specifications

| Inner diameter (mm) | Outer diameter (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Order code |

|---|---|---|---|---|---|---|

| 50-51 | 58.0 | 0.48 | 0.17 | 33 | 0.24 | 531-0050-0000 |

| 60 | 68.0 | 0.405 | 0.145 | 38 | 0.34 | 531-0060-0000 |

| 63-65 | 73.0 | 0.37 | 0.13 | 40 | 0.36 | 531-0065-0000 |

| 70 | 78.0 | 0.345 | 0.125 | 43 | 0.39 | 531-0070-0000 |

| 75-76 | 83.0 | 0.325 | 0.115 | 45 | 0.41 | 531-0075-0000 |

| 80 | 88.0 | 0.305 | 0.11 | 48 | 0.44 | 531-0080-0000 |

| 89-90 | 98.0 | 0.27 | 0.095 | 53 | 0.49 | 531-0090-0000 |

| 100-102 | 108.0 | 0.245 | 0.055 | 58 | 0.52 | 531-0100-0000 |

| 110 | 118.0 | 0.22 | 0.05 | 63 | 0.57 | 531-0110-0000 |

| 114-115 | 123.0 | 0.21 | 0.05 | 66 | 0.59 | 531-0115-0000 |

| 120 | 128.0 | 0.205 | 0.045 | 68 | 0.62 | 531-0120-0000 |

| 125-127 | 133.0 | 0.195 | 0.045 | 71 | 0.64 | 531-0125-0000 |

| 130 | 138.0 | 0.185 | 0.04 | 73 | 0.68 | 531-0130-0000 |

| 140 | 148.0 | 0.175 | 0.04 | 78 | 0.72 | 531-0140-0000 |

| 150-152 | 158.0 | 0.16 | 0.035 | 83 | 0.77 | 531-0150-0000 |

| 160 | 168.0 | 0.15 | 0.035 | 88 | 0.82 | 531-0160-0000 |

| 178-180 | 188.0 | 0.135 | 0.03 | 98 | 0.92 | 531-0180-0000 |

| 200-203 | 208.0 | 0.12 | 0.025 | 108 | 1.04 | 531-0200-0000 |

| 250 | 258.0 | 0.10 | 0.02 | 136 | 1.30 | 531-0250-0000 |

| 280 | 288.0 | 0.085 | 0.02 | 149 | 1.45 | 531-0280-0000 |

| 300 | 309.0 | 0.08 | 0.015 | 159 | 1.73 | 531-0300-0000 |

| 315 | 324.0 | 0.075 | 0.015 | 167.5 | 1.82 | 531-0315-0000 |

| 350 | 359.0 | 0.07 | 0.015 | 185 | 2.01 | 531-0350-0000 |

| 400 | 409.0 | 0.06 | 0.015 | 210 | 2.30 | 531-0400-0000 |

Pressure and vacuum limits are recommended for operation. Bending radius measured internally. Technical changes reserved. All values determined at approx. 20 °C.