NORRES CP PTFE/GLASS-INOX 471 EC

Electrically conductive, chemical-resistant double-layer hose – CP PTFE/GLASS-INOX 471 EC

NORRES CP PTFE/GLASS-INOX 471 EC is a highly flexible, electrically conductive clamp-profile hose with double-layer wall, designed for demanding environments requiring extreme chemical resistance, heat stability, and safe equipotential bonding. The hose withstands up to +270°C and is ideal for conveying hot/cold gases, dust, fibers, and aggressive chemical vapors in explosive zones and tough industrial settings.

Applications

The hose is typically used for:

- Flexible hose/ducting for hot and cold gases, dust, powders, and fibers

- Chemical industry: chemical vapors, vapor return hose at loading arms, paint steam, spray mist extraction

- Explosion hazard zones – suitable for ATEX Zone 22 (inside hose) and Zone 0, 1, 2 for gases

Technical note: The hose fulfills norms for combustible dust aspiration (ATEX 2014/34/EU, 1999/92/EC, TRGS 727), RoHS, and REACH. Other lengths and diameters available upon request.

Properties and Approvals

- Abrasion protection via external clamp profile

- Secure clamping of the wall within the clamp profile

- Extremely flexible and compressible (4:1)

- Very good heat resistance – operating up to 250°C, briefly up to 270°C, usable down to -150°C

- Anti-adhesive, highly resistant to chemicals, alkalis, and acids

- Interior PTFE film with surface resistance < 10⁶ Ω

- Complies with ATEX 2014/34/EU, TRGS 727, RoHS, and REACH

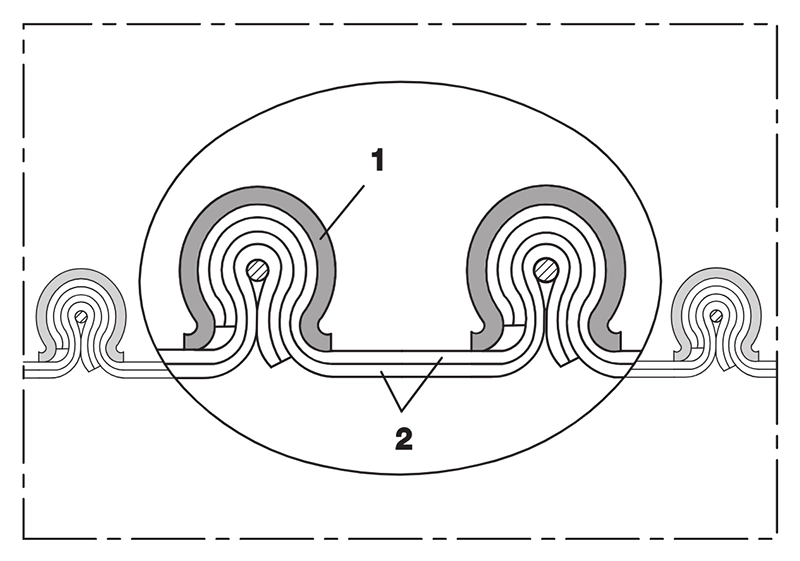

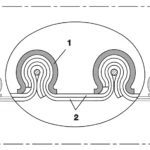

Construction

1 = Clamp profile base of stainless steel (INOX)

2 = Wall: interior semi-conductive PTFE film, exterior special-coated glass fabric

Recommended Accessories

- CLAMP 212, CLAMP 217, CLAMP 213 – hose clamps for assembly and equipotential bonding

- CONNECT 228, CONNECT 270–271 – adapters and molded couplings for process integration

Need technical assistance?

Contact us for guidance on correct hose selection, assembly, equipotential bonding, and ATEX integration in your systems.

FAQ: NORRES CP PTFE/GLASS-INOX 471 EC

Where is this hose used?

For transfer of hot and cold gases, chemical vapors, and dust in process plants, chemical systems, and ATEX zones.

Is the hose electrically conductive?

Yes, with interior semi-conductive PTFE film, low surface resistance, compliant with ATEX and TRGS 727.

How resistant is the hose to heat and chemicals?

Handles up to 250°C in continuous operation, briefly up to +270°C; extremely resistant to alkalis, acids, and chemicals.

Which certifications does it meet?

Meets ATEX 2014/34/EU, TRGS 727, RoHS, REACH.

Which accessories are recommended?

CLAMP 212/213/217 and CONNECT 228/270–271 for safe installation and equipotential bonding.

Related links

Technical specifications

| Inner diameter (mm) | Outer diameter (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Order code |

|---|---|---|---|---|---|---|

| 50-51 | 62.0 | 0.41 | 0.30 | 18 | 0.61 | 471-0050-1003 |

| 70 | 82.0 | 0.34 | 0.21 | 22 | 0.83 | 471-0070-1003 |

| 75-76 | 87.0 | 0.325 | 0.18 | 24 | 0.88 | 471-0075-1003 |

| 100-102 | 112.0 | 0.195 | 0.10 | 28 | 0.86 | 471-0100-1003 |

| 110 | 122.0 | 0.185 | 0.085 | 30 | 0.95 | 471-0110-1003 |

| 114-115 | 127.0 | 0.18 | 0.08 | 32 | 0.99 | 471-0115-1003 |

| 120 | 132.0 | 0.175 | 0.075 | 32 | 1.03 | 471-0120-1003 |

| 150-152 | 162.0 | 0.11 | 0.04 | 38 | 0.86 | 471-0150-1003 |

| 160 | 172.0 | 0.105 | 0.035 | 40 | 0.91 | 471-0160-1003 |

| 200-203 | 212.0 | 0.09 | 0.025 | 48 | 1.13 | 471-0200-1003 |

| 215 | 227.0 | 0.085 | 0.02 | 52 | 1.21 | 471-0215-1003 |

| 300 | 312.0 | 0.055 | 0.01 | 68 | 1.68 | 471-0300-1003 |

Pressure and vacuum limits are recommended for operation. Bending radius measured internally. Technical changes reserved. All values determined at approx. 20 °C.