Delfin MTL 202 ACD LP 1/-D

ACD vacuum with Longopac ESD – dust-free and safe handling of combustible and hazardous dust

The Delfin MTL 202 ACD LP is a compact single-phase industrial vacuum cleaner equipped with the Longopac ESD (antistatic) endless bagging system, designed for dust-free and hygienic disposal of combustible, conductive, or toxic dust in non-classified areas. The unit complies with IEC 60335-2-69 Annex AA for ACD (Applied for Combustible Dust), combining full containment, efficient filtration, and safe dust collection without operator exposure.

- ACD marking: II 1/-D Ex h IIIC T80°C (Internal) Da/-.

- Motor: single-phase 230 V – 2.2 kW – noise level 76 dB(A).

- Filtration: antistatic polyester M-class with Dustop cleaning + HEPA H14 final filter.

- Longopac ESD: antistatic endless bag – dust-free, quick, and flexible waste handling.

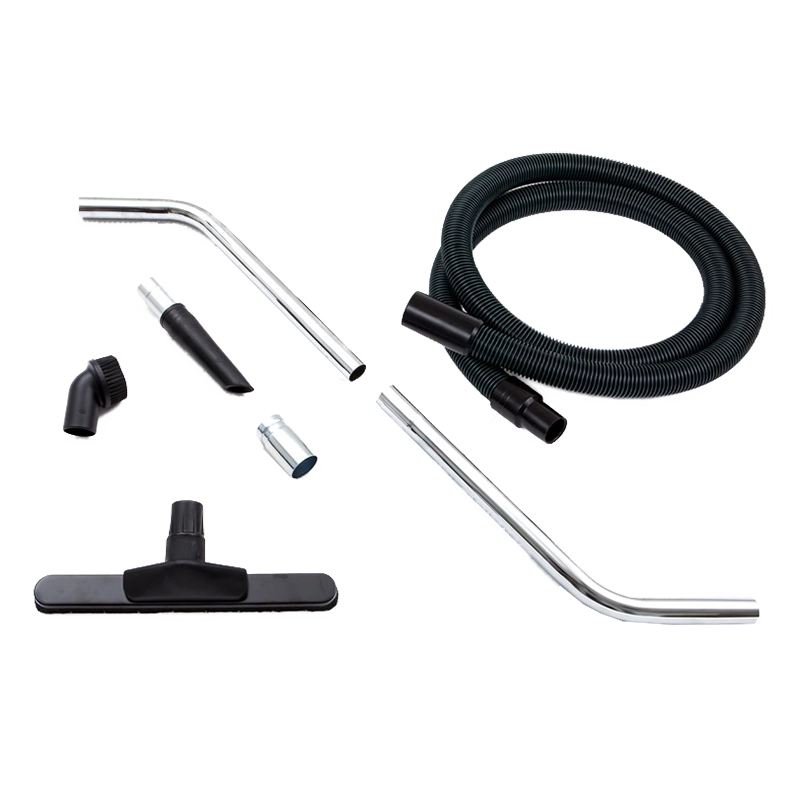

- Supplied with antistatic accessory kit TA.0527.0000 (D40).

Technical design

The tangential inlet with integrated cyclone reduces filter load and stabilises airflow (360 m³/h). The primary filter of 30,000 cm² (antistatic polyester, M-class) is cleaned mechanically by the Dustop system. The final HEPA H14 filter of 20,500 cm² is tested according to EN 1822 (MPPS method) with 99.995 % efficiency. All conductive surfaces and components are ESD-safe.

Longopac ESD – endless bag system

The Longopac system allows dust-free disposal and bag replacement from the outside. Simply pull down the bag, tie it off, and cut – a quick, hygienic, and contamination-free method ideal for controlled environments.

Technical note

ACD vacuums are intended for non-classified areas where hazardous or conductive dust is handled but full ATEX certification is not required. The MTL 202 ACD LP combines ACD-grade containment and filtration with Longopac ESD for dust-free emptying and safe waste management. Always use antistatic or conductive hoses with proper grounding (< 10⁶ Ω) to maintain safe operation.

Need advice on ACD and Longopac solutions?

We can help you choose the right ACD or ATEX-compliant equipment, documentation, and conductive accessories.

FAQ

What does ACD mean?

ACD stands for Applied for Combustible Dust according to IEC 60335-2-69 Annex AA. It defines vacuums designed and tested for safe handling of hazardous or conductive dust in non-classified areas.

What are the advantages of Longopac ESD?

An endless, antistatic bagging system providing dust-free waste handling – no contact with collected material, adjustable bag length, fast sealing, and reduced exposure.

What is included in the TA.0527.0000 (D40) accessory kit?

Approx. 3 m antistatic hose, stainless steel wands (straight + curved), couplings/adapters (50/40), straight connector, conical rubber nozzle, antistatic brush, and dry floor nozzle.

Can it be used in ATEX zones?

No. ACD units are for non-classified areas. For Zone 21 or 22, an ATEX-certified vacuum is required.

Technical specifications

| Parameter | Value |

|---|---|

| ACD marking | II 1/-D Ex h IIIC T80°C (Internal) Da/- |

| Classification | ACD (non-classified area) |

| Voltage / Frequency | 230 V – 50/60 Hz (1~) |

| Power / Current | 2.2 kW / 10 A |

| Max vacuum | 2,500 mm H₂O |

| Max airflow | 360 m³/h |

| Inlet / Diameter | 50 mm (tangential inlet with cyclone) |

| Longopac cassette | ESD version – dust-free endless bag (~ 20 m) |

| Noise level | 76 dB(A) |

| Dimensions (L×W×H) | 54 × 69 × 134 cm |

| Weight | 55 kg |

| Primary filter | Antistatic polyester M-class – 30,000 cm² / Ø 360 mm |

| Filter cleaning system | Dustop – mechanical cleaning |

| HEPA final filter | H14 – 20,500 cm² – 99.995 % (MPPS) |

| Material / Surfaces | ESD-safe conductive surfaces; AISI 304 contact parts |

| Accessories | Antistatic accessory kit TA.0527.0000 (D40) |