Tiger-Vac CD-2600 EX (MFS) 2GD

ATEX Zone 1/21 industrial vacuum cleaner for pharma, cleanrooms and process equipment

The Tiger-Vac CD-2600 EX (MFS) CAT. 2GD Z1-21 is a vertical stainless-steel industrial vacuum cleaner designed for operation in areas with both gas and dust explosion risks. Fully ATEX and IECEx certified (II 1/2GD), it is approved for Zone 1 (gas) and Zone 21 (dust) externally, as well as Zone 0/20 internally. This makes it suitable for the safe recovery of combustible and conductive dust in high-risk environments including pharma, biotech, food production, additive manufacturing and other advanced production setups.

- ATEX third-party certified: II 1/2GD – external: Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65; internal: Ex h IIC T6 Ga / Ex h IIIC T50°C Da.

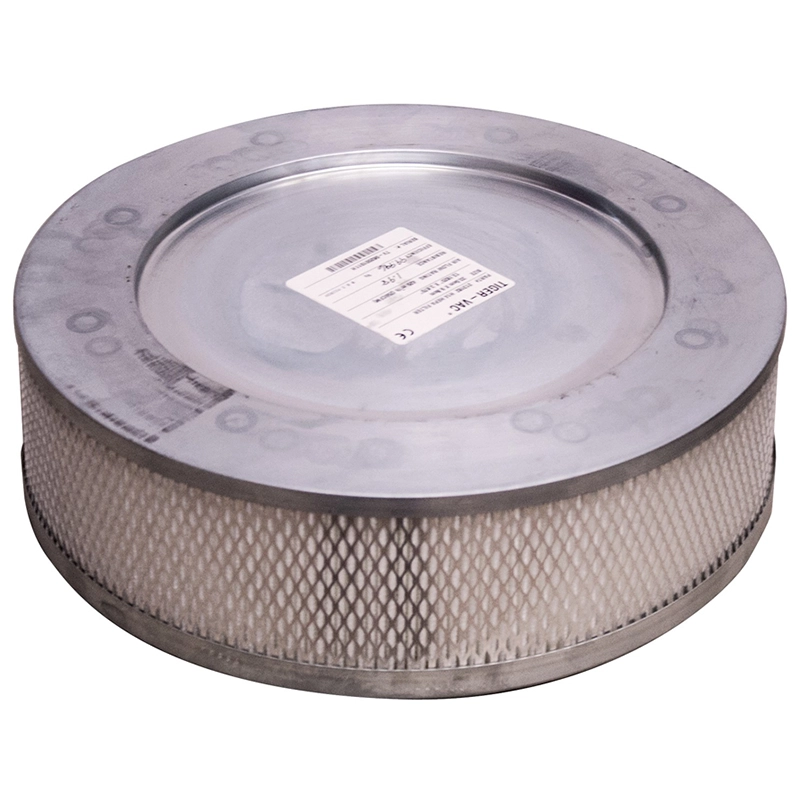

- MFS – Manual Filter Shaker with PTFE-laminated antistatic main filter (SD*) with resistance < 10 Ω.

- Cleanroom compatible down to ISO Class 4 (Class 10).

- Available in two EX-motor variants: 2.2 kW and 4.0 kW TEFC motors.

- Stainless steel 36 L detachable recovery tank (DT).

- Suitable for direct connection to process equipment (tablet presses, capsule machines, filling lines, coating systems, etc.).

Technical design

The CD-2600 EX (MFS) has a slim vertical format that minimises footprint, making it ideal for compact pharma and cleanroom environments. All air-contact components are made of stainless steel for easy cleaning and hygienic operation. The unit is designed for dry recovery but can be paired with an external liquid tank when required.

Safety and certification

- Approved for conductive and combustible dust (Dust Group IIIC) – system resistance below 10 Ω.

- Motor housing meets IP65 requirements for explosive metal dust environments (as specified in the brochure).

- Fully compliant with EN 17348 for combustible dust collection.

- Independently ATEX and IECEx certified by notified body LCIE (0081).

Technical note

The 2GD version differs from the 2D model by being approved for both gas and dust explosive atmospheres. This makes it suitable for hybrid hazard zones typically found around granulation systems, isolators, mixers, solvent-handling areas and environments where combustible dust may coexist with explosive vapours.

Need ATEX 2GD guidance?

We assist with proper zone classification, documentation and selection of the right EX-certified solution.

FAQ

What is the difference between 2D and 2GD?

2GD means the unit is certified for both gas and dust hazards: Zone 0/20 internally and Zone 1/21 externally.

Is it suitable for pharmaceutical cleanrooms?

Yes — it is compatible with ISO Class 4 cleanrooms and commonly installed next to production and processing equipment.

Which motor options are available?

2.2 kW and 4.0 kW EX-db motors, both IECEx certified.

Can it recover conductive metal dust?

Yes — it is certified for Dust Group IIIC and specifically designed for metal dust environments (IP65 motor enclosure).

Which filters can be used?

Standard PTFE-laminated SD* filter, optional HEPA H14 or ULPA U15 (factory aerosol-tested).

Related links

Technical specifications

| Specification | CD-2600 EX (MFS) 2.2 kW | CD-2600 EX (MFS) 4.0 kW |

|---|---|---|

| ATEX marking (int/ext) | II 1/2GD – Ex h IIC T6 Ga / Ex h IIIC T50°C Da (internal), Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 (external) | |

| Zone classification | Zone 0/20 internal / Zone 1/21 external | |

| Voltage / Frequency | 400 V – 50 Hz | 400 V – 50 Hz |

| Phase | Three-phase | Three-phase |

| Power | 2.2 kW (2200 W) | 4.0 kW (4000 W) |

| Current | 4.8 A | 8.7 A |

| Airflow | 212 m³/h | 299 m³/h |

| Vacuum | 2,540 mm H₂O | 3,380 mm H₂O |

| VRV setting | 1,780 mm H₂O | 2,030 mm H₂O |

| Noise level | 68 dB(A) | 68 dB(A) |

| Suction inlet | Ø50 mm | Ø50 mm |

| Filter cleaning | MFS – Manual Filter Shaker | |

| Main filter | PTFE laminated SD* antistatic star filter | |

| HEPA/ULPA (optional) | HEPA H14 / ULPA U15 (EN 1822 tested) | |

| Recovery tank | 36 L detachable tank (DT) | |

| Material | Stainless steel AISI 304/316 | |

| Dimensions (H×W×L) | 191 × 51 × 66 cm | |

| Weight | 112 kg | |

| Accessories | ESD multimeter included – Ø38/Ø50 mm cleanroom, EX and pharma accessories optional | |