Tiger-Vac CD-2000 EX (CFB) PHARMA

ATEX/IECEx 2GD vacuum cleaner for combustible and conductive dust in pharmaceutical environments

The Tiger-Vac CD-2000 EX (CFB) PHARMA is a continuous-duty, 3-phase, third-party ATEX and IECEx certified industrial vacuum cleaner engineered for the safe recovery of combustible and conductive dust in Zone 1/21 and Zone 2/22 environments. The entire construction is made from AISI 304 stainless steel and includes an ULPA U15 final filter, a static dissipative tool kit, and a conductive Collection Filter Bag (CFB) for safe, dust-free disposal in GMP areas.

- ATEX marking: 0081 II 1/2GD – certified by Notify Body LCIE.

- Internal certification: Ex h IIC T6 Ga / Ex h IIIC T50°C Da.

- External certification: Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db – IP65.

- ULPA U15 final filter with 99.999% efficiency at 0.12 µm (MPPS).

- Conductive Filter Bag (CFB) for safe and fully controlled dust disposal.

- Developed for pharmaceutical production, process machinery extraction and conductive dust (<10 Ω).

Technical design

The CD-2000 EX (CFB) PHARMA is built for continuous operation with a fully enclosed 3-phase TEFC explosion-proof motor (2.2 kW). The ULPA filter is aerosol-leak-tested before shipment. Internal Ga/Da certification (Zone 0/20) allows direct recovery of combustible dust inside the tank and filter section. The conductive CFB system ensures dust-free, GMP-compliant disposal.

- Airflow: 212 m³/h

- Vacuum: 2,540 mm H₂O

- 50 L stainless steel recovery tank (AISI 304)

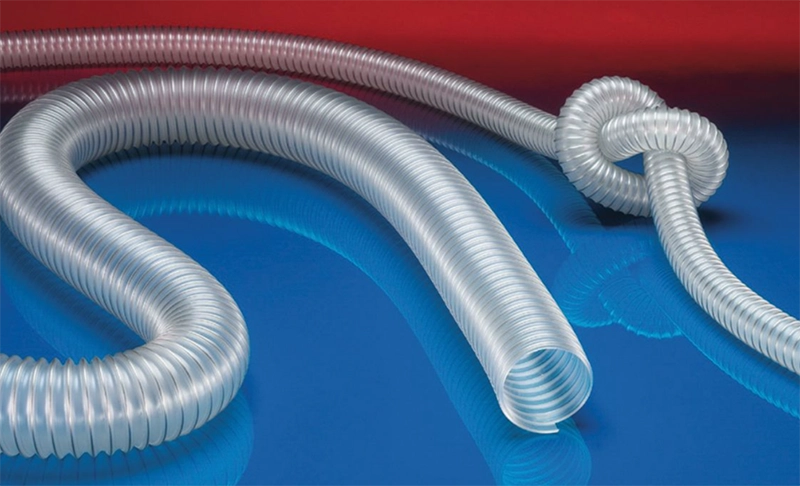

- Static dissipative hose and complete Ø38 mm tool kit included

- Designed for connection to process equipment and for vertical installation

Safety and certification

- Third-party ATEX certified by LCIE (0081) – ensuring full compliance with applicable directives.

- IECEx certified: IECEx LCI 10.0040X.

- Complies with EN 17348 for combustible dust collection.

- Motor and enclosure meet the requirements for conductive metal dust (Dust Group IIIC).

- All components in AISI 304 stainless steel or conductive materials rated below 10 Ω.

Technical note

As a fully certified 1/2GD vacuum cleaner (Zone 0/20 internally and Zone 1/21 externally), the CD-2000 EX (CFB) PHARMA is among the safest solutions for the recovery of combustible and electrically conductive dust. The CFB system delivers dust-free, GMP-compatible waste handling. Always use conductive hoses and accessories, and ensure proper bonding/grounding of the complete system in accordance with TRGS 727, EN 1127-1 and NFPA 77.

Need guidance on ATEX/IECEx vacuum systems?

Get help with equipment selection, documentation, risk assessment and proper grounding in pharmaceutical and process environments.

FAQ

What does 1/2GD certification mean?

The vacuum is certified Zone 0/20 internally (Ga/Da) and Zone 1/21 externally (Gb/Db), allowing safe recovery of combustible dust inside the tank and filter chamber.

Is ULPA filtration required in pharmaceutical environments?

Yes. ULPA U15 is standard on the CD-2000 EX PHARMA series and ensures extremely high filtration efficiency, suitable for GMP and cleanroom production.

What is the purpose of the CFB system?

The Conductive Filter Bag allows dust-free, controlled and antistatic disposal of collected material—essential in pharma, chemical and conductive dust applications.

Can the unit be used for conductive metal dust?

Yes. It is certified for resistivity below 10 Ω and the motor assembly meets IP65 requirements for Dust Group IIIC.

Can it be connected to process machinery?

Yes. The CD-2000 EX PHARMA is designed for fixed installation on process equipment such as tablet presses and capsule machines.

Related links

Technical specifications

| Specification | Data |

|---|---|

| ATEX marking (Int/Ext) | 0081 II 1/2GD – Ex h IIC T6 Ga / Ex h IIIC T50°C Da – Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 |

| Zone classification | Zone 0/20 internal – Zone 1/21 external |

| Voltage / Frequency | 400 V – 50 Hz |

| Motor | 3-phase TEFC explosion-proof motor |

| Power | 2.2 kW |

| Amperage | 4.8 A |

| Airflow | 212 m³/h |

| Vacuum | 2,540 mm H₂O |

| VRV setting | 1,780 mm H₂O |

| Sound level | 68 dB(A) |

| Inlet diameter | 50 mm |

| Primary filter | Epitropic polyester with PTFE (CFB) |

| Final filter | ULPA U15 – 99.999% at 0.12 µm |

| Tank capacity | 50 L – AISI 304 stainless steel |

| Materials | Stainless steel AISI 304 |

| Cable length | 10 m |

| Dimensions (L×W×H) | 64 × 48 × 151 cm |

| Weight | 97 kg |

| Accessories (included) | Ø38 mm static dissipative tool kit, CFB filter bag, ULPA U15 filter |