Tiger-Vac CD-2000 EX (MRPFT) PHARMA

ATEX/IECEx 2GD vacuum cleaner for combustible and conductive dust in pharmaceutical environments

The Tiger-Vac CD-2000 EX (MRPFT) PHARMA is a continuous-duty, 3-phase industrial vacuum cleaner, third-party certified for ATEX and IECEx Zone 1/21 and Zone 2/22 applications. It is equipped with the Manual Reverse Purge with Filter Tubes (MRPFT) system using epitropic polyester/PTFE finger filters, an ULPA U15 final filter and a full set of static dissipative tools. The entire construction is made from AISI 304 stainless steel, making it ideal for GMP and pharmaceutical production.

- ATEX marking: 0081 II 1/2GD – certified by Notify Body LCIE.

- Internal certification: Ex h IIC T6 Ga / Ex h IIIC T50°C Da.

- External certification: Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db – IP65.

- ULPA U15 final filter with 99.999% efficiency at 0.12 μm (MPPS), aerosol-leak-tested.

- MRPFT self-cleaning filter tube system for continuous, efficient dust recovery.

- Designed for pharmaceutical environments, process machinery and conductive dust (<10 Ω).

Technical design

The MRPFT version uses a mechanically actuated filter-tube reverse purge system with epitropic polyester/PTFE fingers, allowing stable filtration during continuous operation. The EX-certified 3-phase TEFC motor (2.2 kW) is built for Dust Group IIIC and requires IP65 protection, as included. ULPA U15 filtration is standard across all PHARMA models.

- Airflow: 212 m³/h

- Vacuum pressure: 2,540 mm H₂O

- 50 L recovery tank in AISI 304 stainless steel

- Ø50 mm suction inlet

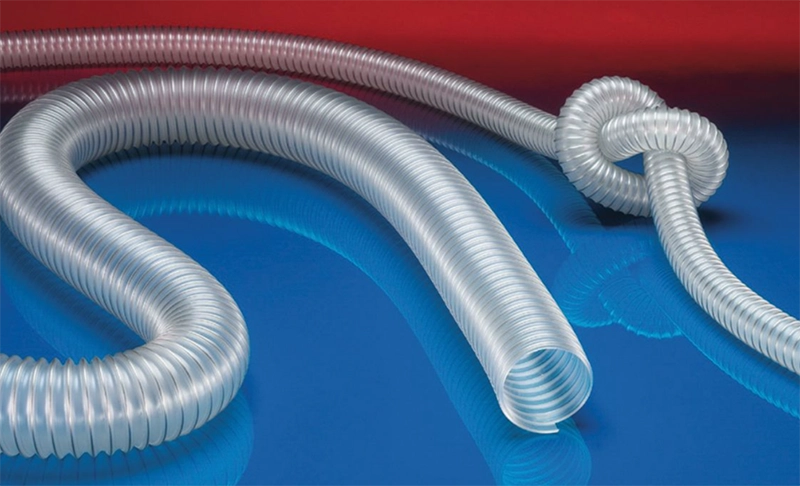

- Complete static dissipative Ø38 mm tool kit included

Safety and certification

- ATEX 1/2GD third-party certification by LCIE – ensuring full legal compliance.

- IECEx certification: IECEx LCI 10.0040X.

- Complies with EN 17348 for combustible dust collection.

- Certified for conductive metal dust – Dust Group IIIC (<10 Ω).

- AISI 304 stainless steel construction suitable for GMP production areas.

Technical note

As a fully certified 1/2GD vacuum cleaner (Zone 0/20 internally and Zone 1/21 externally), the CD-2000 EX (MRPFT) PHARMA is engineered for safe recovery of combustible and electrically conductive dust. The MRPFT finger-filter system provides mechanical filter cleaning without compressed air, making it ideal for continuous operation on tablet presses, capsule machines and powder transfer processes. Always use conductive hoses and ensure proper bonding/grounding according to TRGS 727, EN 1127-1 and NFPA 77.

Need guidance on ATEX/IECEx vacuum systems?

We can help with equipment selection, documentation, risk assessment and proper grounding for pharmaceutical and process environments.

FAQ

What is the difference between the CFB and MRPFT versions?

CFB provides dust-free waste handling via a conductive filter bag, while MRPFT uses a self-cleaning finger-filter system for stable filtration during continuous operation.

Is the unit suitable for conductive metal dust?

Yes – it is certified for Dust Group IIIC and a resistivity of <10 Ω.

Does the ULPA filter require scheduled replacement?

Yes. ULPA U15 is the final filtration stage and must be replaced according to Tiger-Vac’s maintenance intervals to maintain GMP and ATEX compliance.

Can the vacuum be mounted on process machinery?

Yes – the CD-2000 EX PHARMA is designed for tablet presses, capsule filling machines and general process extraction.

Related links

Technical specifications

| Specification | Data |

|---|---|

| ATEX marking (Int/Ext) | 0081 II 1/2GD – Ex h IIC T6 Ga / Ex h IIIC T50°C Da – Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 |

| Zone classification | Zone 0/20 internal – Zone 1/21 external |

| Voltage / Frequency | 400 V – 50 Hz |

| Motor | 3-phase TEFC explosion-proof motor |

| Power | 2.2 kW |

| Amperage | 4.8 A |

| Airflow | 212 m³/h |

| Vacuum pressure | 2,540 mm H₂O |

| VRV setting | 1,780 mm H₂O |

| Sound level | 68 dB(A) |

| Inlet diameter | 50 mm |

| Primary filter | Epitropic polyester with PTFE – MRPFT finger filter |

| Final filter | ULPA U15 – 99.999% at 0.12 µm |

| Tank capacity | 50 L – AISI 304 stainless steel |

| Materials | Stainless steel AISI 304 |

| Cable length | 10 m |

| Dimensions (L×W×H) | 64 × 48 × 151 cm |

| Weight | 97 kg |

| Accessories (included) | Ø38 mm static dissipative tool kit, ULPA U15 filter, MRPFT finger-filter assembly |