Tiger-Vac CD-2600 EX (MRP) 1/2GD

ATEX 1/2GD pharmaceutical vacuum cleaner for Gas Zone 1 and Dust Zone 21 (external) and Zone 0/20 (internal)

The Tiger-Vac CD-2600 EX (MRP) is a fully third-party certified ATEX 1/2GD industrial vacuum system designed for pharmaceutical production, biotechnology, laboratories, API handling and ISO Class 4 cleanrooms. The internal chamber is certified for Zone 0/20 (Category 1G/1D), while the exterior is approved for Zone 1/21 (Category 2G/2D), enabling safe recovery of combustible and conductive dust directly into the stainless-steel tank and filter housing. Its AISI 304/316 construction, static dissipative reverse purge filter cartridge (<10 ohms) and manual MRP cleaning system ensure stable performance in GMP-controlled environments.

Technical design

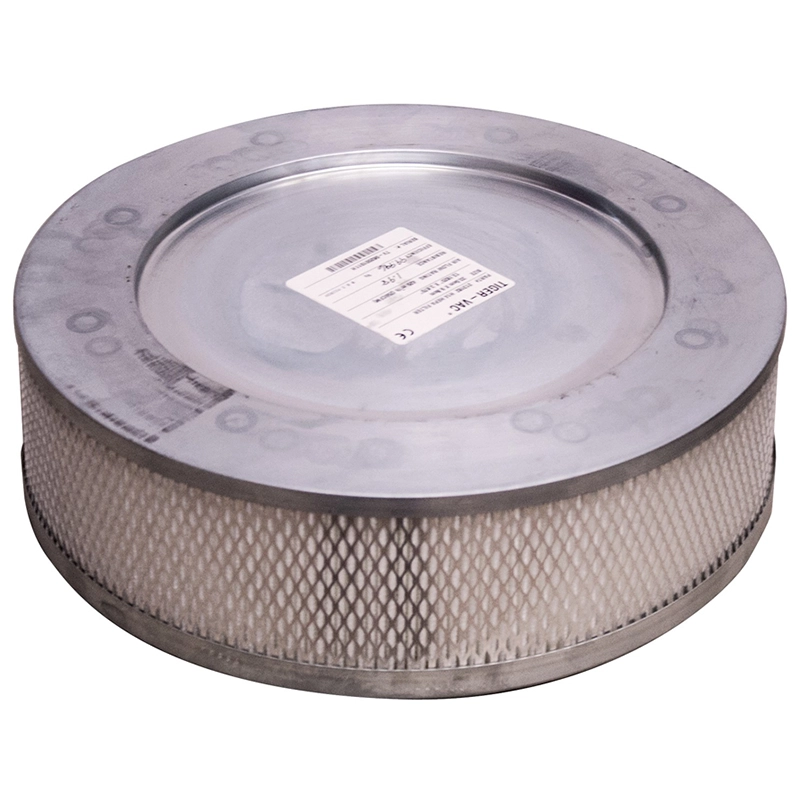

The CD-2600 EX (MRP) is a vertically mounted pharmaceutical model with a 36 L recovery tank and an aluminized spunbond polyester filter cartridge designed for manual reverse purge cleaning without compressed air. Optional HEPA H14 or ULPA U15 final filtration is available, both leak-tested according to EN 1822. The vacuum is compatible with Ø38 mm and Ø50 mm static dissipative tools and hoses for safe operation in ATEX-regulated environments.

Safety and certification

- ATEX marking: II 1/2GD – internal Zone 0/20 (Ga/Da) and external Zone 1/21 (Gb/Db).

- IECEx & ATEX certified by notified body LCIE (0081) – full third-party approval.

- Compliant with EN 17348 (collection of combustible dusts) and IEC 60079 series.

- Reverse purge filter cartridge made from aluminized spunbond polyester (<10 ohms).

- ISO Class 4 cleanroom compatible – suitable for GMP, API and OEB environments.

Technical note

The model is certified for internal Zone 0, meaning it is approved for direct recovery of combustible and conductive dusts inside the tank and filtration chamber. All explosion-proof components are third-party certified, while hoses and accessories follow ATEX/ESD standards but are not individually tested. Always ensure proper grounding during operation. Ambient temperature for dry collector use: -5°C to +37°C.

Need guidance on ATEX 1/2GD vacuum systems?

We support pharma, biotech and cleanroom industries with certified ATEX equipment and documentation.

FAQ

What does ATEX 1/2GD mean?

The vacuum is Category 1 internally (Zone 0/20) and Category 2 externally (Zone 1/21), certified by LCIE.

Is it suitable for pharmaceutical production?

Yes. The CD-2600 EX (MRP) is ISO Class 4 cleanroom compatible and built in AISI 304/316 stainless steel.

How is the filter cleaned?

Via the Manual Reverse Purge system (MRP), which cleans the static dissipative cartridge without compressed air.

Can disposable collection bags be used?

No – there are no static-dissipative collection bags available for this model. Recovery is done directly into the stainless tank.

Related links

Technical specifications – Tiger-Vac CD-2600 EX (MRP)

| Specification | 2.2 kW model | 3.7–4.0 kW model |

|---|---|---|

| ATEX marking (int/ext) | II 1/2GD – Ex h IIC T6 Ga / Ex db h IIB T4 Gb – Ex h IIIC T50°C Da / Ex h tb IIIC T135°C Db | |

| Zone classification | Internal Zone 0/20 – External Zone 1/21 | |

| Voltage / Frequency | 400 V – 50 Hz | 400 V – 50 Hz |

| Phase | Three-phase | Three-phase |

| Power | 2.2 kW (2,200 W) | 3.7–4.0 kW (3,700–4,000 W) |

| Current draw | 4.8–5.2 A | 7.4–8.7 A |

| Airflow | 212–299 m³/h | 299–340 m³/h |

| Vacuum pressure | 2,540 mm H₂O | 3,300–3,560 mm H₂O |

| VRV setting | 1,780 mm H₂O | 2,030 mm H₂O |

| Sound level | 68 dB(A) | 68 dB(A) |

| Suction inlet | 50 mm | 50 mm |

| Filter cleaning | Manual Reverse Purge (MRP) | |

| Filter cartridge | Aluminized spunbond polyester – <10 ohms | |

| Final filtration (optional) | <td colspan="2"||