Tiger-Vac CD/EUR-50L EX DT (MRP) 1/2GD

ATEX 1/2GD industrial vacuum for Zones 1, 2, 21 and 22 with internal Zone 20 protection

The Tiger-Vac CD/EUR-50L EX DT (MRP) 1/2GD is a fully ATEX- and IECEx-certified industrial vacuum cleaner designed for the safe recovery of combustible, conductive and metallic dusts as well as flammable gases and vapours. Classified as II 1/2GD, it provides full internal Zone 20 protection (1D/1G) and external Zone 1/21 and Zone 2/22 protection (2GD). The system includes an efficient MRP – Manual Reverse Purge filter cleaning mechanism, a static dissipative reverse-purge cartridge, a U15 ULPA final filter and a robust SS304 stainless-steel construction.

- ATEX category II 1/2GD – internal Zone 20/0 and external Zone 1/21/22.

- IECEx certified (IECEx LCI 10.0040X).

- U15 ULPA final filter included: 99.999% @ 0.12 μm.

- MRP filter cleaning – manual reverse purge without compressed air.

- Static-dissipative filter cartridge and components (<10 Ω).

- 4.0 kW TEFC explosion-proof/dust ignition-proof motor for continuous duty.

- 50 L SS304 detachable recovery tank (DT), compatible with poly liners.

- IP65 dust-tight housing and ISO Class 4 cleanroom compatibility.

Certification & safety

According to ATEX certificate LCIE 03 ATEX 6295 X, the vacuum is certified for use in explosive atmospheres involving both gases and dusts. Internal classification is Ex h IIC T6 Ga and Ex h IIIC T50°C Da, providing the highest protection inside the filter chamber and tank. External classification is Ex db h IIB T4 Gb and Ex h tb IIIC T135°C Db IP65, allowing installation in Zone 1, Zone 2, Zone 21 and Zone 22.

- Less than 10 Ω resistivity – full ESD protection.

- ULPA leak-tested according to EN 1822 and factory aerosol testing.

- Approved for both GAS (G) and DUST (D) hazardous areas.

Construction & performance

The MRP system uses an internal aluminised, static-dissipative spunbond cartridge that is cleaned manually via a reverse purge action, without the need for compressed air. Combined with a stainless-steel 304 construction and ULPA U15 filtration, the vacuum is ideal for high-risk environments where explosive gases and dusts may coexist.

- Airflow: 299 m³/h

- Vacuum: 3,380 mm H₂O

- VRV setting: 2,030 mm H₂O

- Sound level: 75 dB(A)

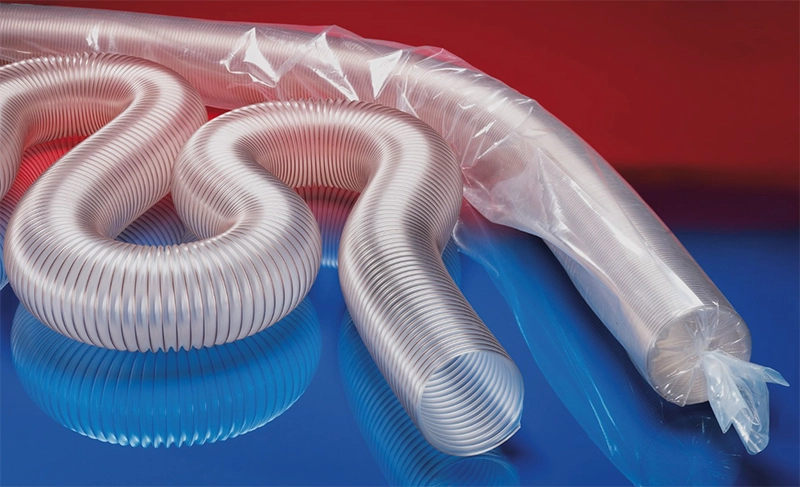

- Suction inlet: Ø63.5 mm

Applications

This 1/2GD model is designed for environments where explosive gas and dust atmospheres may be present simultaneously, and where maximum internal protection combined with certified external zone compliance is required:

- Pharma & biotech: ULPA U15, SS304, ISO Class 4.

- Additive manufacturing: conductive and metallic powders.

- Food production: flour, sugar, starch and fine powders.

- Chemical industry: combustible vapours + combustible dust.

- Process industries: suitable for Zone 1/2/21/22.

Technical note

In ATEX 1/2GD applications, correct bonding and grounding of hoses, tools, piping and operator workflow is mandatory according to TRGS 727, EN 1127-1 and NFPA 77. Although the vacuum is static-dissipative (<10 Ω), safe operation depends on proper grounding of the entire installation and the use of EX-rated accessories.

Need help selecting ATEX equipment for Zones 1/2/21/22?

We provide guidance on ATEX documentation, zone classification and safe recovery of combustible dusts and gases.

FAQ

What does 1/2GD mean?

Internal Zone 20 (1D) + internal Zone 0 (1G) + external Zones 1/21/22 (2GD).

Is it suitable for both gas and dust?

Yes – fully ATEX-certified for GAS (G) and DUST (D) atmospheres.

Is the ULPA filter included?

Yes – U15 ULPA is standard.

Which filtration system does it use?

MRP – Manual Reverse Purge with a static-dissipative purge cartridge.

Is it suitable for pharmaceutical use?

Yes – SS304 construction, ULPA filtration and ISO Class 4 compatibility.

Related articles

Technical specifications

| Specification | Data |

|---|---|

| ATEX classification | II 1/2GD – Ex h IIC T6 Ga · Ex h IIIC T50°C Da (internal) · Ex db h IIB T4 Gb · Ex h tb IIIC T135°C Db IP65 (external) |

| Certificates | IECEx LCI 10.0040X · LCIE 03 ATEX 6295 X |

| Voltage | 400 V |

| Frequency | 50 Hz |

| Phase | 3-phase |

| Power | 4 kW / 4,000 W |

| Amperage | 8.2 A |

| Airflow | 299 m³/h |

| Vacuum | 3,380 mm H₂O |

| VRV | 2,030 mm H₂O |

| Sound level | 75 dB(A) |

| Suction inlet | Ø63.5 mm |

| Filter cleaning | MRP – Manual Reverse Purge |

| Main filter | Static-dissipative reverse-purge cartridge |

| Final filter | ULPA U15 – 99.999% @ 0.12 µm |

| Recovery tank | 50 L SS304 (DT) |

| Materials | Stainless steel 304 (except cart) |

| Dimensions | 81 × 69 × 210 cm |

| Cable length | 10 m |

| Weight | 60 kg |