Tiger-Vac EXP1-IT (63L) EX (CFE) HEPA 2GD

Description

The Tiger-Vac EXP1-IT (63L) EX (CFE) HEPA is an ATEX II 2GD certified inert vacuum cleaner designed for the safe recovery and inertization of highly reactive, conductive and combustible metal powders in Zone 1 and Zone 21. The system uses Tiger-Vac’s Water Mix Immersion Technology, where dust is directed into a controlled water bath that reduces reactivity, heat generation and ignition risk. The design is tested and certified for aluminum, magnesium, zirconium and other commercial alloys and functions as a high-grade safety component in critical environments. The unit can be equipped with a dedicated dust extraction arm and an optional rupture disk, making it ideal for capturing reactive dust directly at the source.

Applications

The EXP1-IT (63L) is used in processes involving aluminum, magnesium, zirconium, titanium alloys and advanced AM powders. It is suitable for additive manufacturing (SLM/LPBF), powder metallurgy, laboratories, R&D environments, electronics production, aerospace, defense, pyrotechnics and other operations where combustible or self-heating metal dust must be inertized in Zone 1 and Zone 21. When equipped with a dust extraction arm, the unit can act as a fixed process extraction point above printers, sieves, blending stations or machining equipment, capturing the most critical dust fractions before they spread.

Industries

Metal additive manufacturing, powder metallurgy, aerospace and defense, electronics and battery production, pyrotechnics, laboratories and R&D, high-tech metal processing, component manufacturing and any process handling reactive metal powders where documented inertization is required.

Technical Construction

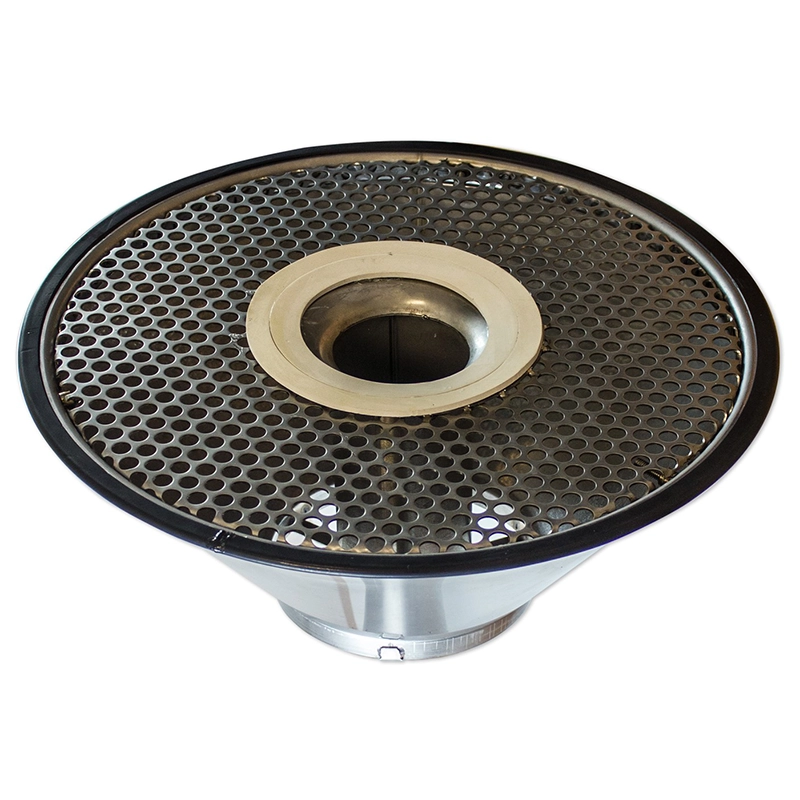

Dust passes through a diffuser directly into the water bath where it is neutralized. Gas from reactive metals is safely released through the integrated degassing vent, and an optional rupture disk provides additional overpressure protection. Above the liquid, a complete filtration package with a Coalescing Filter Element (CFE) and an aerosol leak-tested HEPA H14 filter (99.995% at 0.3 μm) ensures particle containment and clean exhaust air. The system is built in stainless steel (AISI 304) and includes a detachable tank (DT), Mist Arrestor Pack, stainless sieve basket, liquid level indicator, Reverse Pulse filter cleaning, TEFC motor and an antistatic tool kit. The dust extraction arm is available with various nozzles for source extraction.

Safety

The EXP1-IT (63L) uses water as the only inertizing medium and is certified for handling reactive metals under controlled conditions. Correct liquid level, grounding and SDS compliance must be ensured before operation. Organic dust must not be recovered. Accessories are not ATEX type-tested but selected for ESD-controlled environments. The unit functions as a high-specification safety component in Zone 1 and Zone 21, and the optional rupture disk and dust extraction arm increase operational safety at high-risk process points.

Inert or ATEX – do you know the difference?

Learn when inertization is mandatory, when ATEX alone is insufficient and how Water Mix immersion protects against ignition of reactive metal powders.

Accessories

Standard: antistatic hose, stainless steel wands, floor tool, round brush, conical nozzle, Tiger Claw tool, cleaning brush, multimeter, stainless sieve basket, Mist Arrestor Pack, CFE and HEPA H14 filtration. Options: dust extraction arm with multiple hoods, rupture disk (factory installed), stainless steel cart upgrade.

Technical Note

The EXP1-IT (63L) EX (CFE) HEPA is among the most advanced mobile inert vacuum systems for Zone 1 and Zone 21. Its Water Mix immersion design, HEPA H14, CFE, degassing, optional rupture disk and source-capture dust extraction arm make it a documented safety component for processes handling extremely reactive metal powders.

FAQ

- Which metals can be inertized? Aluminum, magnesium, zirconium, titanium alloys and other reactive metal powders.

- Can oil be used? No. Water is the only certified inertization medium.

- Can organic dust be recovered? No. Organic dust must never be collected with an inert vacuum.

- What does the rupture disk do? It relieves overpressure in fault scenarios and increases safety in Zone 1 and Zone 21.

- Why choose a dust extraction arm? It captures the most reactive dust directly at the source before it enters the workspace.

- How is the tank emptied? The detachable recovery tank allows safe and controlled handling of inertized sludge.

All values provided by the manufacturer at approx. 20 °C. Subject to technical changes.

| Model | EXP1-IT (63L) EX (CFE) HEPA |

| ATEX | II 2GD Ex d IIA T3 Gb / Ex t IIIC T200°C Db IP6X |

| Zone | Zone 1 / 21 external, metal dust zone 20 internally in the bath |

| Type | Immersion Separator, Water Mix Inert System |

| Voltage | 230 V |

| Frequency | 50 Hz |

| Phase | Single phase |

| Motor | 1000 W TEFC |

| Airflow | 224 m³/h |

| Vacuum | 1550 mm H₂O |

| Sound Level | 78–85 dB(A) |

| Inlet | 50 mm |

| Filters | CFE + HEPA H14 |

| Tank | Detachable recovery tank (DT), nominal 63 L |

| Liquid | Water-based inertization |

| Material | Stainless steel AISI 304 |

| Dimensions | H160 × W61 × L79 cm |

| Weight | 76.2 kg |

| Included Accessories | Antistatic hose, stainless wands, floor tool, round brush, conical nozzle, Tiger Claw, sieve basket, Mist Arrestor Pack, CFE/HEPA |

| Options | Dust extraction arm, rupture disk (factory installed), stainless steel cart upgrade |