Tiger-Vac CD-1200 EX SS AUT 3GD

ATEX dust collector for process-related extraction of airborne dust in Zone 2 and 22

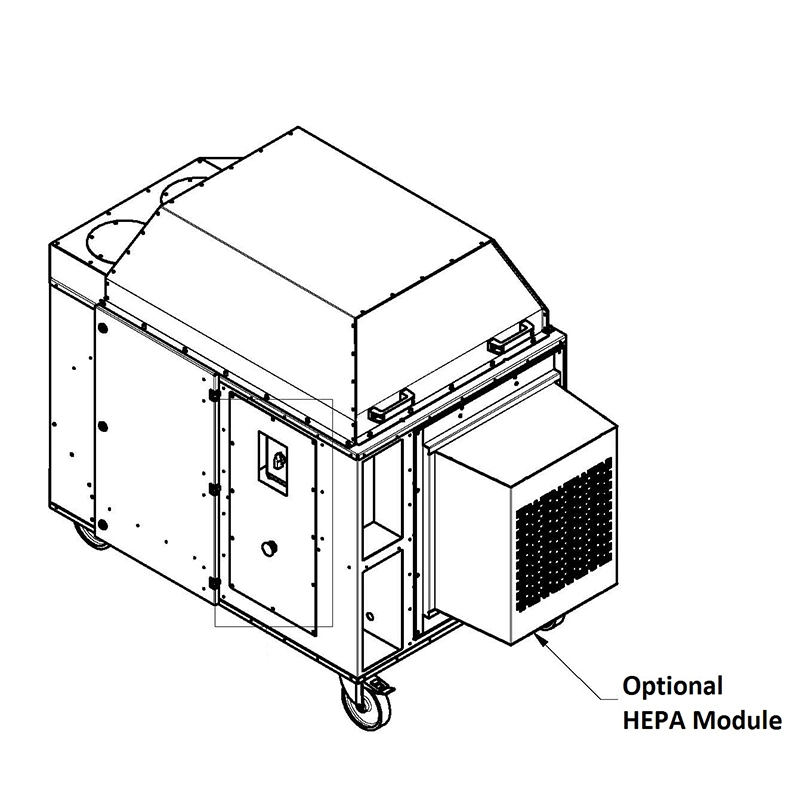

Tiger-Vac CD-1200 EX SS AUT 3GD is a mobile ATEX dust collector designed for process-related extraction of airborne and suspended dust in industrial environments where explosive atmospheres occur only occasionally. The unit is intended for use in ATEX Zone 2 (gas) and Zone 22 (dust) and is suitable for applications with a lower risk level than category 1/2GD equipment.

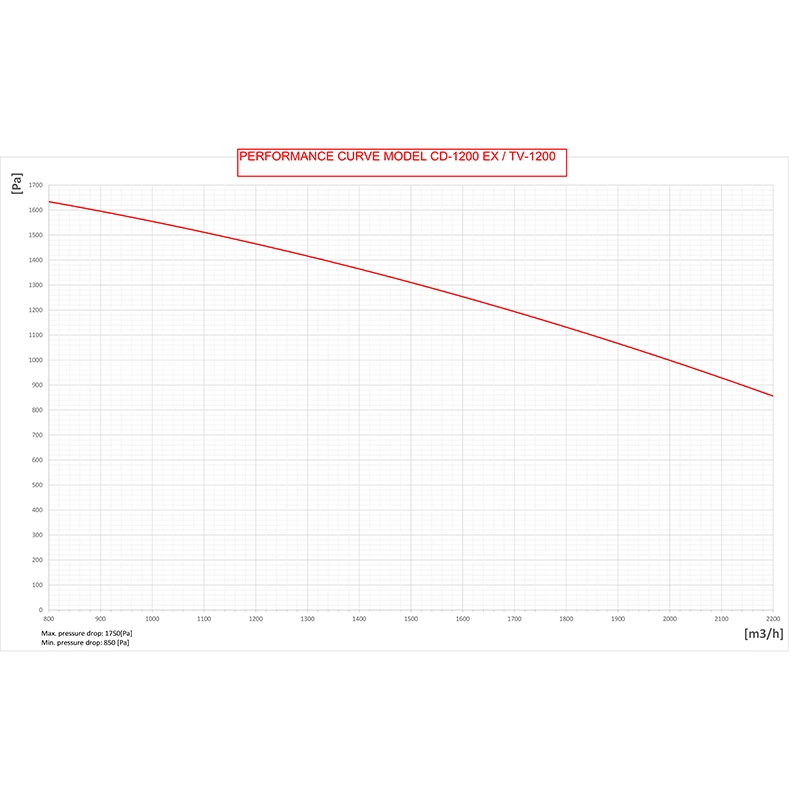

The dust collector operates on the principle of low vacuum and high airflow, enabling effective capture of dust directly at the source. With a documented airflow of 2,000 m³/h, the CD-1200 EX can be connected to two Ø150 mm extraction arms or to a single Ø200 mm hose or duct connection.

Applications

CD-1200 EX SS AUT 3GD is used for process-related point extraction in areas where explosive atmospheres are present only sporadically. The automatic filter cleaning system makes this model particularly suitable for continuous or dust-intensive processes where stable airflow is required without manual intervention.

- Point extraction at open process points in Zone 2 and Zone 22

- Process extraction during filling, dosing and material handling

- Extraction above conveyors and material transfer points

- Recovery of airborne, combustible and conductive dust

Key features

- ATEX category: II 3GD

- Suitable for Zone 2 (gas) and Zone 22 (dust)

- Airflow: 2,000 m³/h

- Automatic filter cleaning – Automatic Reverse Purge (ARP)

- Conductive aluminized spun-bond filter cartridges

- Stainless steel construction (AISI 304)

Technical design

The dust collector is equipped with a continuous duty 3-phase TEFC motor. The motor itself is third-party certified, while the complete machine is self-certified in accordance with the ATEX Directive for category 3GD.

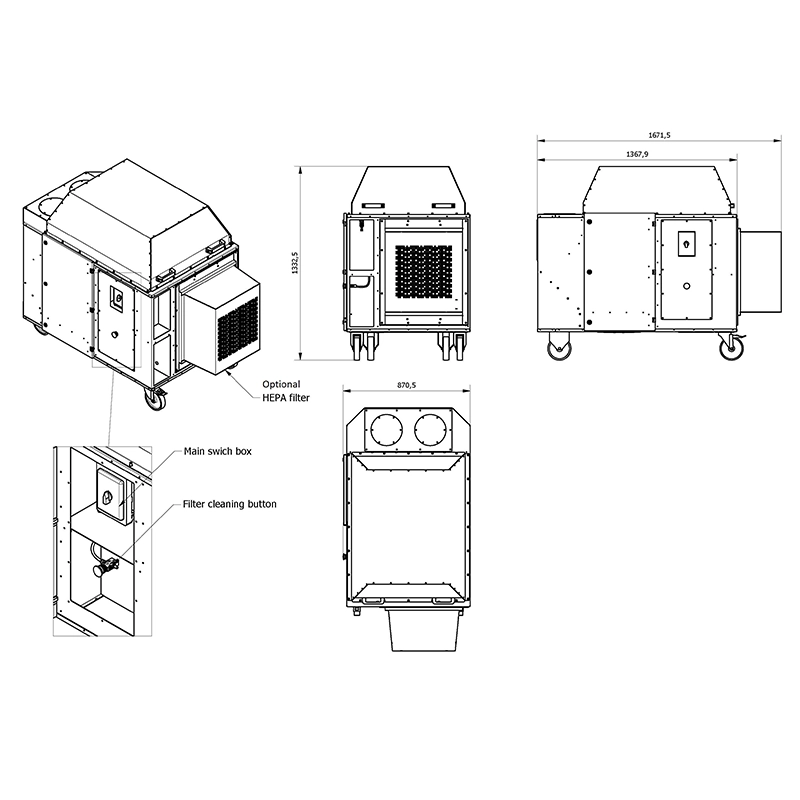

The filtration section consists of conductive filter cartridges that are cleaned automatically using a reverse purge compressed-air system with an integrated air tank. Collected dust is discharged into a pull-out dust drawer with a capacity of 10 litres.

All wheels and structural components are electrically conductive, and the unit is designed as an ESD-safe system to reduce the risk of electrostatic discharge.

Optional equipment

- Extraction arms: 2 × Ø150 mm or 1 × Ø200 mm

- HEPA filter module (optional)

- Differential pressure gauge (filter blockage indicator)

- Wall mounting bracket for extraction arms

- Hemipleat® filter cartridges

Safety and standards

- ATEX category: II 3GD

- Gas protection: Ex nA IIB T3 Gc (Zone 2)

- Dust protection: Ex tc IIIB T120°C Dc IP55 (Zone 22)

- Standard: EN 17348 – DT (Combustible Dust Collection)

Technical note

The CD-1200 EX SS AUT 3GD is designed for continuous recovery of dry, combustible and conductive dust in environments with occasional explosion risk.

The unit is not intended for continuous explosive atmospheres and is not suitable for the extraction of explosive gases.

Need assistance?

Contact our specialists for advice on ATEX dust collectors and process extraction solutions.

Related articles

- Process dust requires proximity

- ATEX ABC – before sparks, there are choices

- ATEX approval is no longer enough – know EN 17348

FAQ

Which ATEX zones is the dust collector suitable for?

The unit is suitable for Zone 2 (gas) and Zone 22 (dust).

Is the unit third-party certified?

The complete machine is self-certified for ATEX category 3GD. The installed 3-phase TEFC motor is third-party certified.

How are the filters cleaned?

Filters are cleaned automatically using the Automatic Reverse Purge (ARP) compressed-air system.

What distinguishes the AUT version from the MAN version?

The AUT version features automatic filter cleaning and is suitable for continuous or dust-intensive operation.

Technical specifications

| ATEX category | II 3GD |

| Gas zone | Zone 2 |

| Dust zone | Zone 22 |

| Motor | 3-phase TEFC, continuous duty (third-party certified) |

| Power | 4 kW |

| Voltage / frequency | 400 V / 50 Hz |

| Airflow | 2,000 m³/h |

| Sound level | 74 dB(A) |

| Suction inlet | 2 × Ø150 mm or 1 × Ø200 mm |

| Filter cleaning | Automatic Reverse Purge (ARP) |

| Filter type | Conductive aluminized spun-bond cartridges |

| Dust recovery | Pull-out dust drawer – 10 litres |

| Dimensions (L × W × H) | 137 × 87 × 135 cm |

| Weight | 215 kg |