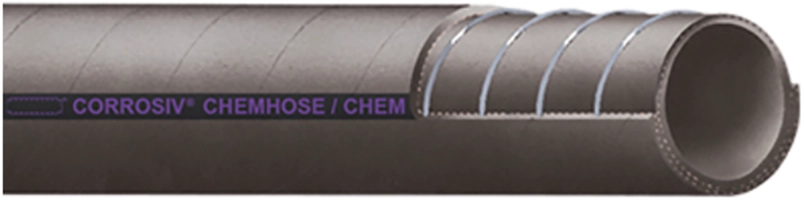

BAGGERMAN CORROSIV®/SP/EN

Chemical hose for high-concentration acids and bases

BAGGERMAN CORROSIV®/SP/EN is a suction and discharge hose designed for the transfer of acids, alkalis and cleaning agents at high concentrations. The hose is made of electrically conductive EPDM on both the inner and outer layers and meets the requirements of EN 12115:2011 and TRbF 131, part 2, § 5.5. It is suitable for use in ATEX zones where static electricity must be safely dissipated.

Technical note

CORROSIV®/SP/EN is particularly suitable for aggressive media such as acids, lye, hot water and cleaning agents. The EPDM material offers excellent heat resistance and chemical resistance, while the conductive construction makes it suitable for explosive atmospheres. Reinforced with textile plies and steel wire, the hose is both flexible and robust for suction and discharge applications. Note that it is not resistant to hydrocarbons.

Need a chemical hose for acids and bases?

Contact us for technical advice and correct dimensioning of EPDM hoses for chemical industry and process plants.

Technical specifications

| Standard | EN 12115:2011 / TRbF 131, part 2, § 5.5 |

| Working pressure (WP) | 16 bar |

| Burst pressure (BP) | 64 bar |

| Vacuum | 0.9 bar |

| Temperature range | –35 °C … +95 °C (depending on medium), cleaning up to +130 °C |

| Electrical resistance (inner layer) | Conductive < 10⁶ Ω |

| Electrical resistance (outer layer) | Conductive < 10⁶ Ω |

| Layer resistance | Antistatic < 10⁹ Ω |

| Inner hose | EPDM, smooth, black |

| Outer hose | EPDM, fabric pattern, black |

| Reinforcement | Textile plies and steel wire |

FAQ: CORROSIV®/SP/EN chemical hose

Which media is the hose suitable for?

Acids, alkalis, hot water and cleaning agents at high concentration.

Can it be used in ATEX zones?

Yes, it complies with EN 12115:2011 and can be used in explosive atmospheres where static electricity must be safely discharged.

Is the hose resistant to oil and hydrocarbons?

No, this version is not resistant to hydrocarbons.

Which couplings are recommended?

Kamlock type C/E and safety clamps type 5561 in stainless steel.

Related links

- ATEX ABC: Before sparks, there are choices

- The invisible weakest link

- Know your Ohm – know your ATEX risk

Recommended accessories

- 5561 Safety clamps

- 5600 Kamlock type C

- 5601 Kamlock type E

Conductive EPDM chemical hose for acids, bases and cleaning agents in ATEX zones.

| Art.no. | Inner Ø (mm) | Wall (mm) | Outer Ø (mm) | Bending radius (mm) | Weight (kg/m) | Length (m) |

|---|---|---|---|---|---|---|

| 3830025000 | 25 | 6.0 | 37 | 150 | 0.780 | 40 |

| 3830032000 | 32 | 6.0 | 44 | 175 | 1.030 | 40 |

| 3830038000 | 38 | 6.5 | 51 | 225 | 1.250 | 40 |

| 3830050000 | 50 | 8.0 | 66 | 275 | 2.100 | 40 |

| 3830063000 | 63 | 8.0 | 79 | 300 | 2.540 | 40 |

| 3830075000 | 75 | 8.0 | 91 | 350 | 2.800 | 40 |

| 3830100000 | 100 | 8.0 | 116 | 450 | 4.100 | 40 |

Note: Maximum working temperature depends on the medium. The hose can be supplied in custom lengths as required.