Depureco DF075 DEX 1/3D (0,75 kW)

Dust collector for use in ATEX Zone 22

What type of product is this?

Depureco DF075 DEX 1/3D is a mobile dust collector designed to capture airborne dust in production environments and process machinery where the spread of combustible and ignitable dust must be prevented. The unit is intended for industrial process extraction and point extraction and is not a conventional vacuum cleaner, but a filter-based extraction unit with high air flow.

Typical tasks and applications

DF075 DEX 1/3D is used in processes where dust is released into the air during normal operation and where controlled extraction at the source is required. Typical applications include:

- Emptying of bags and big bags into mixers and process equipment

- Filling and dosing of powdered raw materials

- Extraction at open process points and machine openings

- Point extraction at workstations with dust-generating processes

- Capture of airborne dust inside and around process machinery

Typical industries

Depureco DF075 DEX 1/3D is used in a wide range of industries where handling of combustible dust is part of the production process, including:

- Food industry

- Feed and grain industry

- Chemical industry

- Plastics and polymer production

- Pharmaceutical industry

- Biotechnology and laboratory environments

- Wood and furniture industry

- Metal and powder handling

Need help?

Contact our experts who are ready with knowledge about ATEX dust collectors and mobile filter units.

Technical design

DF075 DEX 1/3D is built as a mobile filter unit with an ATEX-certified electric fan generating a high and stable air flow through the dust collector. Unlike a conventional vacuum cleaner, the unit is designed for continuous extraction of air and airborne dust from processes and work areas.

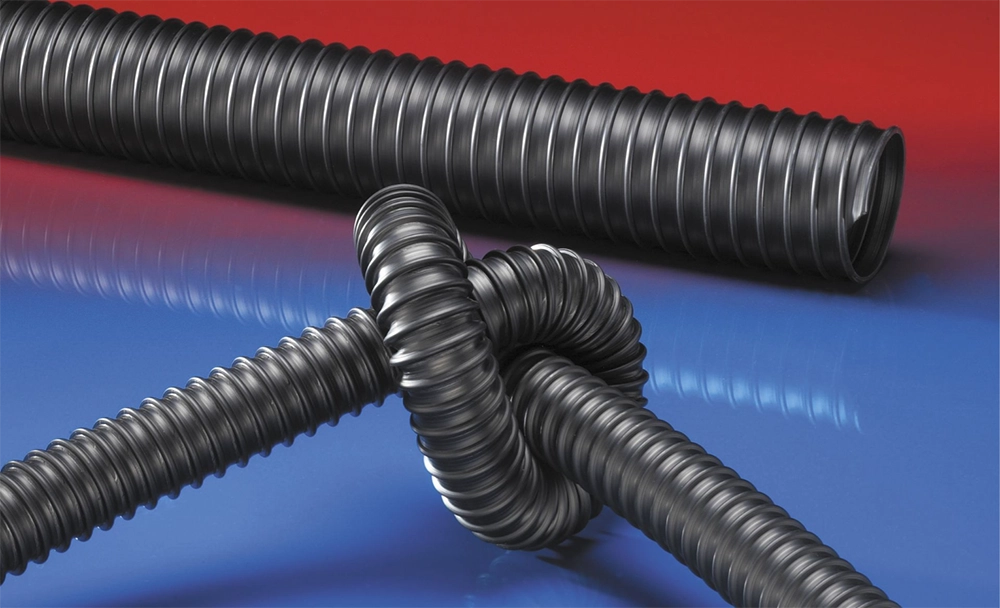

The dust collector can be used for point extraction via one or more extraction arms or connected directly to process equipment using conductive hoses. Dust-laden air is transported from the process into the filter unit, where dust is retained by the filter media and collected in the bin.

As standard, the unit is equipped with an antistatic polyester star filter in filter class M with manual filter cleaning. Optional configurations include H13 HEPA filtration and alternative filter media. For applications within food, pharmaceutical and biotech industries, the filter housing and collection bin can be supplied in stainless steel.

Additional accessories and configuration

To achieve optimal performance and correct process extraction, Depureco DF075 DEX 1/3D must be configured with suitable accessories for the specific application. The dust collector is supplied as the filter and extraction unit, and in most applications additional extraction equipment and connections must be selected.

Depending on the application, the dust collector can be configured with, for example:

- ATEX-approved extraction arm in a standard version or stainless steel version (e.g. 3 m, Ø100 or Ø150)

- Flanged connections for hoses and extraction arms in multiple diameters

- Conductive hoses and hose clamps for ATEX-compliant process extraction

- Additional filtration options, including antistatic PTFE filter (class M) or H13 HEPA secondary filter (EN 1822-5)

- Alternative collection bin, e.g. 100 litres

- Silencer kit for noise reduction

- Filter housing and collection bin in AISI 304 stainless steel for food, pharma and biotech applications

The selection of accessories depends on whether the dust collector is used for point extraction, connected directly to process equipment, or integrated into a solution with air recirculation. We recommend assessing the complete configuration to ensure performance, occupational safety and compliance with applicable ATEX and workplace safety requirements.

ATEX zones and certification

Depureco DF075 DEX 1/3D is marked II 1/3D Ex h IIIC T140°C Da/Dc and is designed as a “Dry Type” dust collector in accordance with EN 17348.

ATEX category 1/3D means that the dust collector is certified for safe use when ATEX Zone 20 may occur inside the unit, and when the unit is used in ATEX Zone 22, where combustible and ignitable dust is present only occasionally and for short periods.

- Inside the dust collector: ATEX Zone 20

- Use in the surrounding area: ATEX Zone 22

- Antistatic filter media and grounding as part of the ATEX safety concept

Compliance with EN 17348 confirms that the dust collector is specifically designed for industrial dust collection in potentially explosive atmospheres. The manufacturer states involvement of notified bodies, including TÜV NORD for EU Type Examination and RINA for ongoing surveillance of production and the quality system.

FAQ

Is DF075 DEX 1/3D a vacuum cleaner?

No. It is an industrial dust collector with high air flow, intended for process extraction and point extraction—not for manual cleaning like a conventional vacuum cleaner.

Can the dust collector be used for process extraction?

Yes. DF075 DEX 1/3D can be used for process extraction at machines and work processes where dust is generated, provided the installation is correctly designed and applicable workplace safety requirements are met.

When is a HEPA filter necessary?

A HEPA filter (H13/H14) is typically required when extracted air is recirculated back into the work area. Recirculation is only acceptable when effective cleaning of the extracted air can be documented. The required filtration level depends on the dust type and the risk assessment for the specific process.

What does manual filter cleaning mean in practice?

Manual filter cleaning is performed using the integrated cleaning system to maintain air flow during operation and ensure stable filtration performance.

Relevant articles

Technical specifications

| ATEX marking | II 1/3D Ex h IIIC T140°C Da/Dc |

| Suitable ATEX zone | ATEX Zone 22 |

| Motor / fan | 3D ATEX-certified fan |

| Motor power | 0.75 kW (1 HP) |

| Voltage / frequency | 400 V / 50–60 Hz |

| IP class / insulation class | IP55 / F |

| Maximum vacuum | 185 / 200 / 180 mm H₂O (depending on inlet) |

| Available static pressure | 180 / 192 / 170 mm H₂O (depending on inlet) |

| Maximum air flow | 300 / 600 / 800 m³/h (depending on inlet) |

| Noise level | 65 dB(A) |

| Inlet diameter | Ø70 / Ø100 / Ø120 mm |

| Primary filter | Star filter |

| Filter media | Antistatic polyester |

| Filter class | M (EN 60335-2-69 / IFA BGIAM-PES) |

| Filter surface | 24,000 cm² |

| Filter cleaning | Manual |

| Collection bin | 65 litres (option: 100 litres) |

| Bin material | AISI 304 stainless steel |

| Operating temperature | -20 °C / +40 °C |

| Dimensions (L × W × H) | 660 × 800 × 1,630 mm |

| Weight | 110 kg |

| Grounding | Included |

| HEPA filter (option) | H13 – EN 1822-5 |

| HEPA filter surface (option) | 12,000 cm² |

| HEPA filter media (option) | Fiberglass |