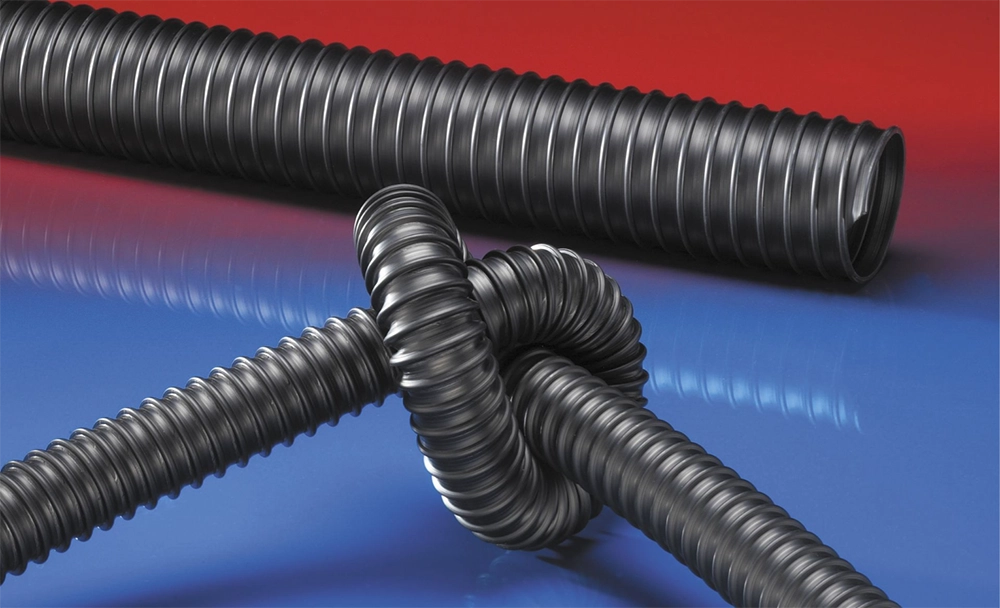

NORRES AIRDUC® PE 362 EC (MD)

Electrically conductive PE hose for ATEX – NORRES AIRDUC® PE 362 EC (MD)

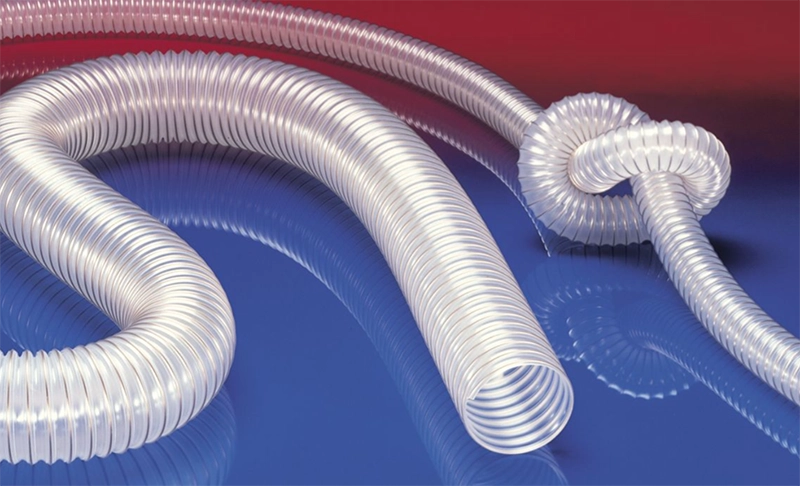

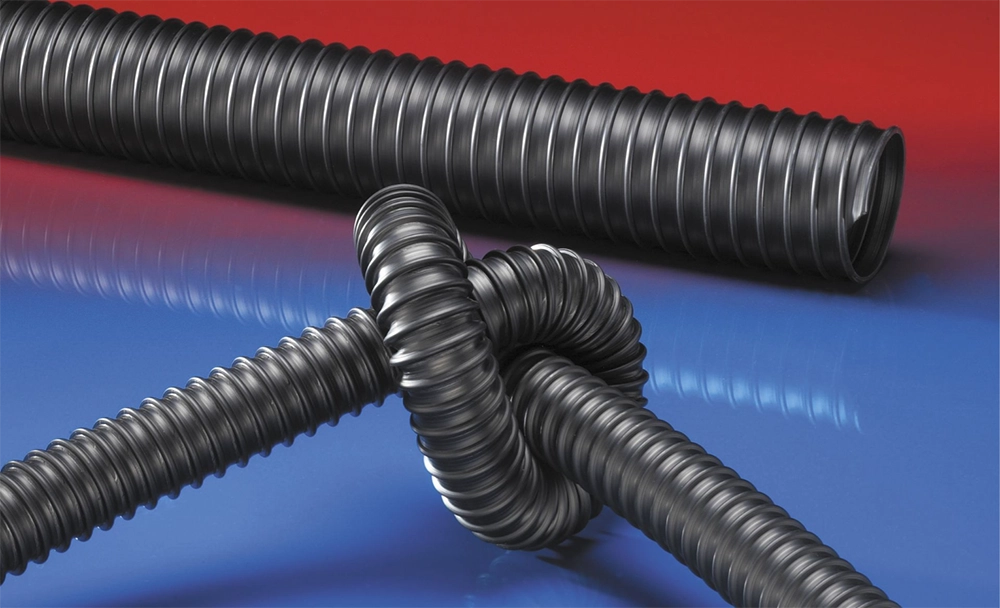

The AIRDUC® PE 362 EC (MD) is a medium-duty, electrically conductive polyethylene hose for ATEX applications, ventilation and chemical process extraction.

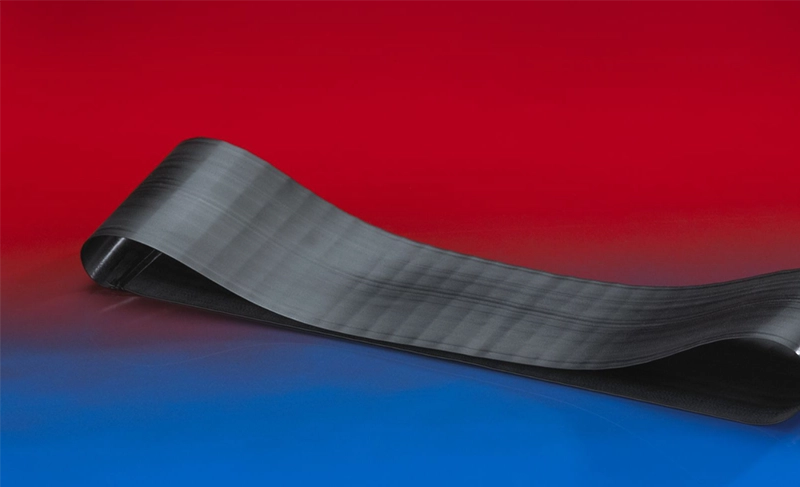

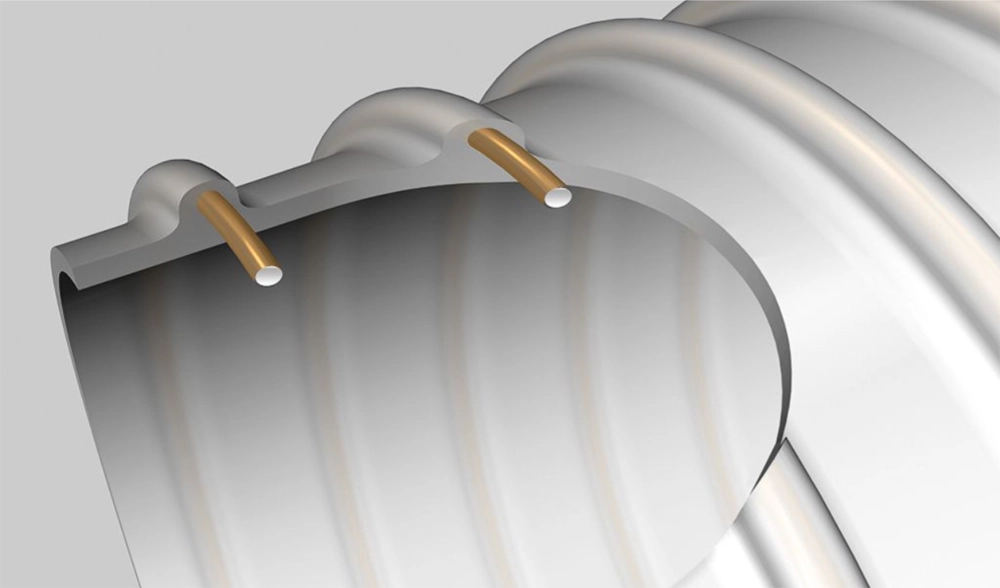

It features a robust embedded steel wire helix and a conductive PE wall (<10³ Ω), ensuring reliable discharge of static electricity under demanding industrial conditions – such as in mining, tunnelling, chemical and ventilation systems.

Strengths and applications

With a medium wall thickness of approx. 0.8 mm, the hose offers excellent chemical resistance and withstands acids and alkalis.

It is suitable for aggressive gases as well as dust, fibres and powders.

Compliant with ATEX Zones 20, 21 and 22 (dust/powder inside and outside) and for the transport of flammable and non-flammable liquids and gases (Zones 0, 1, 2).

Temperature range: −35 to +80 °C.

Approvals and construction

Complies with ATEX 2014/34/EU, TRGS 727, RoHS and REACH, and meets all requirements for conductive ventilation hoses in potentially explosive atmospheres.

The spring steel wire embedded in the hose wall provides additional strength and high operational reliability.

Need technical guidance on ATEX hoses?

Contact us for advice on sizing, selection and safe integration of conductive hoses for ATEX and chemical/industrial applications.

FAQ: Electrically conductive PE hose for ATEX

Which environments are recommended for this hose?

Industrial process systems, chemical and mining extraction, ventilation and all ATEX Zone 20/21/22 applications.

Is it ATEX and ESD approved?

Yes – the AIRDUC® PE 362 EC (MD) has an electrical resistance below 10³ Ω and is fully ATEX and ESD compliant.

Which media and chemicals can it handle?

The hose has excellent resistance to strong acids, alkalis, dust, vapours and aggressive atmospheres.

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Order No. |

|---|---|---|---|---|---|---|---|

| 40 | 48.00 | 0.78 | 0.79 | 35.00 | 0.27 | 10 | 362-0040-1003 |

| 50–51 | 60.00 | 0.66 | 0.67 | 42.00 | 0.32 | 10 | 362-0050-1003 |

| 60 | 70.00 | 0.56 | 0.57 | 50.00 | 0.37 | 10 | 362-0060-1003 |

| 75–76 | 84.00 | 0.43 | 0.44 | 62.00 | 0.45 | 10 | 362-0075-1003 |

| 80 | 89.00 | 0.40 | 0.41 | 66.00 | 0.47 | 10 | 362-0080-1003 |

| 100–102 | 112.00 | 0.32 | 0.33 | 82.00 | 0.57 | 10 | 362-0100-1003 |

| 110 | 122.00 | 0.29 | 0.30 | 90.00 | 0.62 | 10 | 362-0110-1003 |

| 120 | 132.00 | 0.26 | 0.28 | 98.00 | 0.67 | 10 | 362-0120-1003 |

| 125–127 | 137.00 | 0.25 | 0.27 | 102.00 | 0.70 | 10 | 362-0125-1003 |

| 150–152 | 162.00 | 0.21 | 0.23 | 122.00 | 0.80 | 10 | 362-0150-1003 |

| 160 | 172.00 | 0.20 | 0.22 | 130.00 | 0.84 | 10 | 362-0160-1003 |

| 200–203 | 213.00 | 0.16 | 0.18 | 162.00 | 1.01 | 10 | 362-0200-1003 |

| 250 | 263.00 | 0.14 | 0.15 | 202.00 | 1.22 | 10 | 362-0250-1003 |

| 305 | 319.00 | 0.12 | 0.13 | 246.00 | 1.46 | 10 | 362-0305-1003 |

If listed as “production length” only, a minimum order quantity of 150 m applies. Positive and negative pressure ratings are recommended operating limits. Bending radius measured along the inner curve of the hose. We reserve the right to make technical modifications. All values measured at 20 °C (approximate).