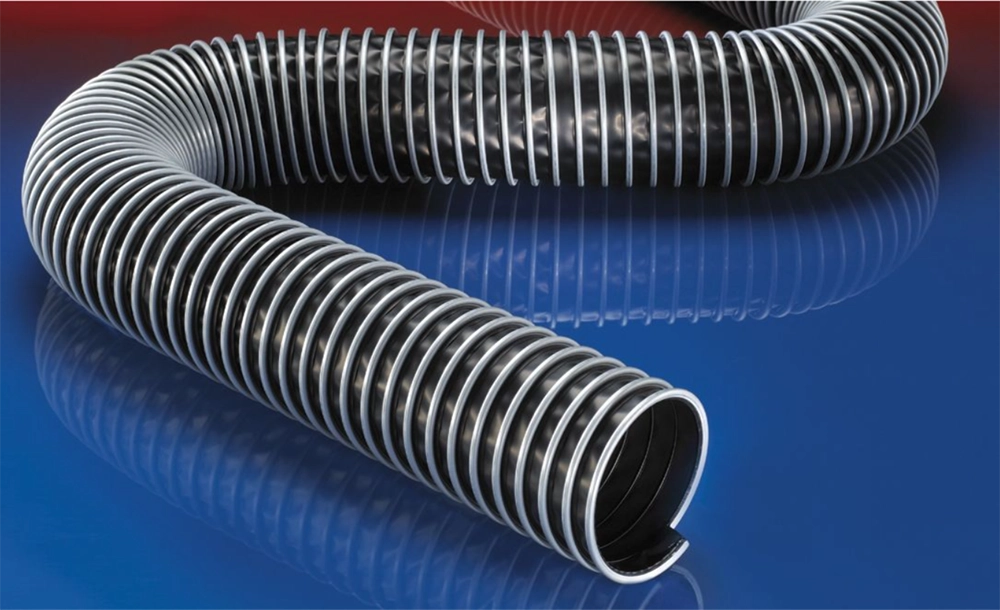

NORRES AIRDUC® PUR 356 AS (XHD)

Antistatic PUR hose for extremely abrasive materials – super heavy duty

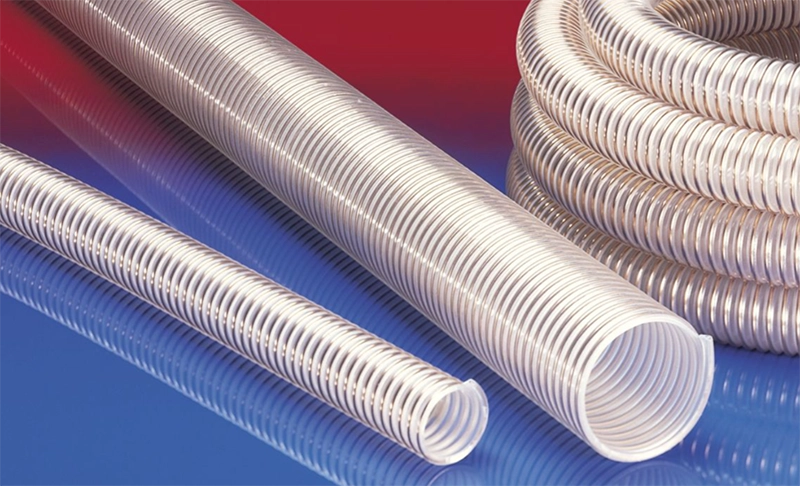

NORRES AIRDUC® PUR 356 AS (XHD) is an extra-strong, antistatic and microbe-resistant hose made of ester-polyurethane (Pre-PUR®) with an embedded spring steel wire. Designed for conveying and extraction of highly abrasive materials such as granules, sand, gravel, dust and powders in demanding industrial environments – including ATEX zones.

Applications

Ideal for use in the plastics and chemical industries, silos and tank systems, vacuum and pressure conveying, granulate and powder transport, dosing systems, big-bag unloading, mills, extruders, vacuum trucks, suction and discharge systems, roof gravel spreading, sand-blasting and surface preparation, as well as industrial cleaning in explosion-hazard areas (zones 20/21/22 inside).

Properties and approvals

- Super heavy duty design with reinforced wear zones for maximum service life.

- Permanently antistatic wall: electrical and surface resistance < 10⁹ Ω (ISO 8031, TRGS 727, NFPA 652).

- Complies with ATEX Directive 2014/34/EU (1999/92/EC) for conveying of flammable dusts and liquids in zones 20-22 (inside) and gases in zones 0-2.

- Extremely high abrasion resistance and excellent flexibility even at low temperatures.

- Resistant to oil, gasoline, chemicals, microbes and hydrolysis.

- Temperature range: −40 °C to +90 °C (short term +125 °C).

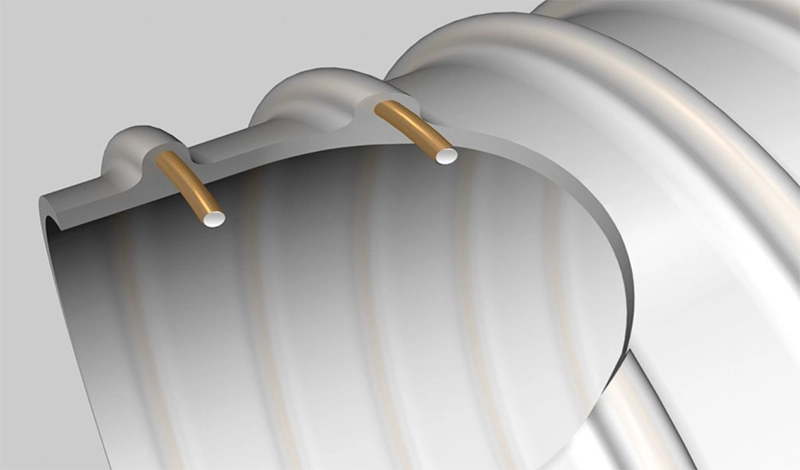

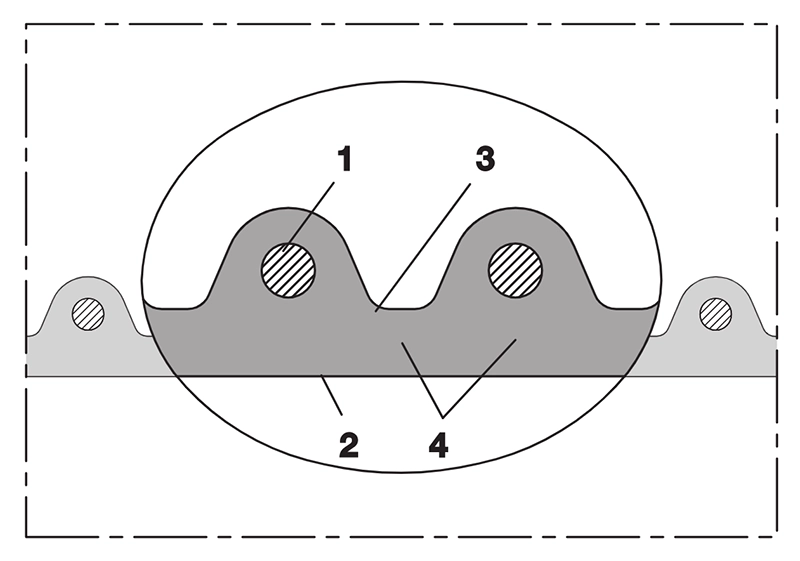

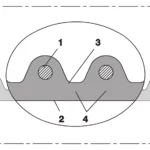

Construction

1 = Embedded spring steel wire

2 = Wall made of permanently antistatic ester-based polyurethane (Pre-PUR®)

3 = AIRDUC® profile with additional wear reinforcement

4 = Smooth inner and outer surfaces for optimal flow and easy cleaning

Recommended accessories

- CLAMP 211 / 216 – stainless-steel hose clamps with equipotential bonding

- CONNECT 228 – adapter and transition fittings

- CONNECT 240 / 241 AS – ATEX-safe couplings for suction and pressure systems

- CONNECT 245 VAC-TRUCK – couplings for vacuum trucks and industrial vacuums

Contact us for advice on proper installation, equipotential bonding and ATEX-compliant setup.

Need technical assistance?

Get professional advice on the selection, assembly and integration of flexible antistatic hoses for conveying granules, dust and other abrasive media in ATEX-classified zones.

FAQ: NORRES AIRDUC® PUR 356 AS (XHD)

What is this hose used for?

For conveying and extraction of highly abrasive materials such as granules, sand, dust and powders in industrial and ATEX environments.

Is the hose antistatic?

Yes – the wall is permanently antistatic (< 10⁹ Ω) according to ISO 8031 and TRGS 727, suitable for zones 20/21/22 (inside).

Is it food-grade?

No – this version is designed for industrial and ATEX-classified use, not for food applications.

What are the temperature and pressure limits?

−40 °C to +90 °C (short term +125 °C). Pressure and vacuum values depend on diameter – see table below.

Which accessories are recommended?

Use CLAMP 211/216 and CONNECT fittings (228 – 245 VAC-TRUCK) depending on the system and diameter.

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Order No. |

|---|---|---|---|---|---|---|

| 32 | 43.00 | 5.235 | 1.000 | 90 | 0.68 | 356-0032-0000 |

| 38 | 49.00 | 4.475 | 1.000 | 104 | 0.79 | 356-0038-0000 |

| 40 | 51.00 | 4.270 | 1.000 | 109 | 0.82 | 356-0040-0000 |

| 45 | 56.00 | 3.825 | 1.000 | 129 | 0.91 | 356-0045-0000 |

| 50 | 61.00 | 3.470 | 1.000 | 134 | 1.00 | 356-0050-0000 |

| 51 | 62.00 | 3.200 | 1.000 | 134 | 1.02 | 356-0051-0000 |

| 55 | 66.00 | 3.170 | 1.000 | 151 | 1.09 | 356-0055-0000 |

| 60 | 71.00 | 2.920 | 1.000 | 156 | 1.18 | 356-0060-0000 |

| 65 | 76.00 | 2.705 | 1.000 | 169 | 1.27 | 356-0065-0000 |

| 70 | 82.00 | 2.520 | 1.000 | 186 | 1.37 | 356-0070-0000 |

| 75–76 | 88.00 | 2.355 | 1.000 | 195 | 1.47 | 356-0076-0000 |

| 80 | 92.00 | 2.220 | 1.000 | 205 | 1.55 | 356-0080-0000 |

| 90 | 103.00 | 2.195 | 1.000 | 250 | 2.06 | 356-0090-0000 |

| 100–102 | 115.00 | 1.890 | 1.000 | 272 | 2.31 | 356-0102-0000 |

| 110 | 123.00 | 1.805 | 1.000 | 300 | 2.48 | 356-0110-0000 |

| 125–127 | 140.00 | 1.565 | 0.890 | 336 | 2.84 | 356-0127-0000 |

| 150–152 | 165.00 | 1.305 | 0.735 | 435 | 3.72 | 356-0152-0000 |

| 160 | 173.00 | 1.255 | 0.700 | 470 | 3.91 | 356-0160-0000 |

| 180 | 193.00 | 1.120 | 0.620 | 830 | 4.38 | 356-0180-0000 |

| 200–203 | 216.00 | 0.955 | 0.550 | 950 | 6.02 | 356-0203-0000 |

| 225 | 239.00 | 0.900 | 0.495 | 1175 | 6.65 | 356-0225-0000 |

| 250 | 264.00 | 0.810 | 0.445 | 1300 | 7.35 | 356-0250-0000 |

| 275 | 289.00 | 0.735 | 0.405 | 1453 | 8.07 | 356-0275-0000 |

| 300 | 314.00 | 0.675 | 0.375 | 1575 | 8.78 | 356-0300-0000 |

Overpressure and underpressure values are recommended operating limits. The bending radius is measured through the inner hose curve. Technical modifications reserved. All values determined at ≈ 20 °C.