NORRES CLAMP 212

Bridge clamp for externally corrugated hoses – quick and tight assembly

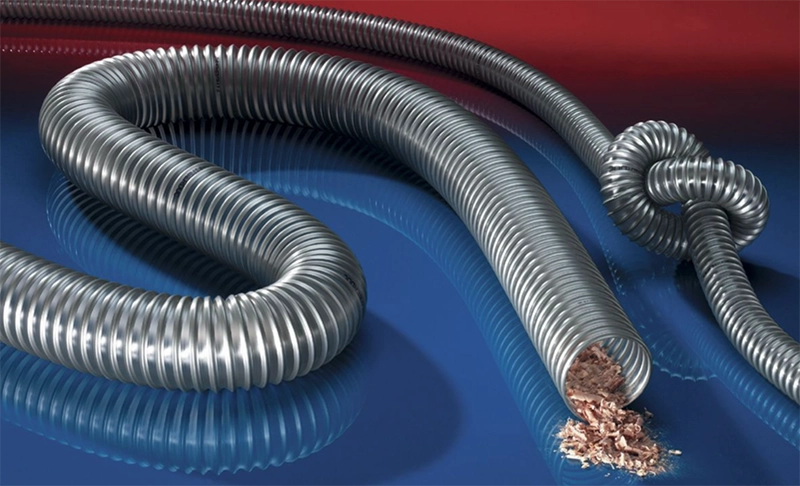

The NORRES CLAMP 212 is a robust bridge clamp designed for secure, almost leak-free fastening of externally corrugated spiral hoses such as AIRDUC®, PROTAPE®, and CP series. Its special bridge geometry spans the corrugations of the hose, ensuring uniform clamping all around. Reusable, easy to fit, and ideal for industrial extraction, ventilation, and conveying systems.

Properties and construction

- Almost leak-free and highly reliable clamping thanks to a specially shaped bridge design.

- Quick installation, reusable, and suitable for service replacement.

- Materials (W2): band and bridge made of stainless steel 1.4301 (AISI 304), housing made of 1.4016 (AISI 430), screw galvanised steel.

- Manufactured according to DIN 3017 and compliant with RoHS and REACH.

- Band widths 5 / 9 / 12 mm depending on size.

Applications

For fastening spiral hoses in extraction, ventilation, and material-handling systems – for example AIRDUC®, PROTAPE®, CP series, and PROTAPE® TPE 326 MEMORY.

Technical note

In ATEX installations, continuous electrical contact between machine, coupling, and hose is essential for proper equipotential bonding. Bridge clamps such as CLAMP 212 provide metal-to-metal contact across the hose corrugations and are therefore often the preferred choice for antistatic or electrically conductive hoses. Select the clamping range to match the actual outer diameter of the hose and fitting.

Recommended accessories

- CONNECT 228 / 233 – Adapters and fittings for AIRDUC® / PROTAPE® hoses.

- CONNECT 270–271 – Stainless / hygienic couplings for process and food applications.

Need help with correct installation?

Contact us for guidance on clamp selection, equipotential bonding, and ATEX-compliant integration with your NORRES hose systems.

FAQ: NORRES CLAMP 212

What is the NORRES CLAMP 212 used for?

CLAMP 212 is used to secure externally corrugated spiral hoses such as AIRDUC®, PROTAPE®, and CP series. It provides a tight and uniform seal across the corrugations.

How does a bridge clamp differ from a standard hose clamp?

A bridge clamp has a raised bridge that spans the corrugations of the hose. It prevents deformation and ensures tight, even compression – particularly important for spiral hoses.

Can CLAMP 212 be used in ATEX areas?

Yes. The clamp provides metal-to-metal contact and can be used in ATEX-classified zones when combined with antistatic or electrically conductive hoses and proper equipotential bonding.

What materials is the clamp made of?

Band and bridge: stainless steel 1.4301 (AISI 304).

Housing: stainless steel 1.4016 (AISI 430).

Screw: galvanised steel.

How do I choose the correct size?

Determine the actual outer diameter of the hose and select a clamp whose clamping range covers this dimension. The technical table lists the suitable ranges for each hose series.

Related links

Technical specifications – sizes and compatibility

The table shows the nominal clamping range and the hose series each variant fits. Group headers indicate which hose types and sizes the following variants are designed for. Always select according to the actual outer diameter of the hose or fitting – not only the nominal size.

| Suitable hose I.D. (mm) | Clamping range (mm) | Band width (mm) | Order No. |

|---|---|---|---|

| AIRDUC® & PROTAPE® Ø 44 mm | |||

| 13–16 | 9–19 | 5 | 212-0009-0000 |

| 15–18 | 13–20 | 5 | 212-0013-0000 |

| 18–26 | 17–27 | 5 | 212-0017-0000 |

| 22–28 | 20–28 | 5 | 212-0020-0000 |

| 25–29 | 22–37 | 9 | 212-0022-0000 |

| 30–35 | 27–47 | 9 | 212-0027-0000 |

| 32–37 | 29–47 | 9 | 212-0029-0000 |

| 38–44 | 35–55 | 9 | 212-0035-0000 |

| CP Ø 38–65 mm, PROTAPE® TPE 326 MEMORY Ø 51–65 mm | |||

| 38–45 | 35–55 | 9 | 212-0035-2002 |

| 50–55 | 45–65 | 9 | 212-0045-2002 |

| 60–65 | 55–75 | 9 | 212-0055-2002 |

| AIRDUC® & PROTAPE® Ø 45 mm, CP & PROTAPE® TPE 326 MEMORY Ø 70 mm | |||

| 45–50 | 40–60 | 9 | 212-0040-0000 |

| 50–55 | 45–65 | 9 | 212-0045-0000 |

| 60–65 | 55–75 | 9 | 212-0055-0000 |

| 70–75 | 65–85 | 9 | 212-0065-0000 |

| 80–85 | 75–95 | 9 | 212-0075-0000 |

| 90–95 | 85–105 | 9 | 212-0085-0000 |

| 100–105 | 95–115 | 9 | 212-0095-0000 |

| 110–115 | 105–125 | 9 | 212-0105-0000 |

| 120–125 | 115–135 | 9 | 212-0115-0000 |

| 130–135 | 125–145 | 9 | 212-0125-0000 |

| 140–145 | 135–155 | 9 | 212-0135-0000 |

| 150–155 | 145–165 | 9 | 212-0145-0000 |

| 160–165 | 155–175 | 9 | 212-0155-0000 |

| 170–175 | 165–185 | 9 | 212-0165-0000 |

| 180–185 | 175–195 | 9 | 212-0175-0000 |

| 190–195 | 185–205 | 9 | 212-0185-0000 |

| 200–205 | 195–215 | 9 | 212-0195-0000 |

| 210–215 | 205–225 | 12 | 212-0205-0000 |

| 220–225 | 215–235 | 12 | 212-0215-0000 |

| 250–255 | 245–265 | 12 | 212-0245-0000 |

| 260–265 | 255–275 | 12 | 212-0255-0000 |

| 270–275 | 265–285 | 12 | 212-0265-0000 |

| 280–285 | 275–295 | 12 | 212-0275-0000 |

| 300–305 | 295–315 | 12 | 212-0295-0000 |

| 310–315 | 305–325 | 12 | 212-0305-0000 |

| 320–325 | 315–335 | 12 | 212-0315-0000 |

| 350–355 | 345–365 | 12 | 212-0345-0000 |

| 370–375 | 365–385 | 12 | 212-0365-0000 |

| 400–405 | 395–415 | 12 | 212-0395-0000 |

| 450–455 | 445–465 | 12 | 212-0445-0000 |

| 500–505 | 495–515 | 12 | 212-0495-0000 |

| 510–535 | 505–545 | 12 | 212-0505-0000 |

| 550–575 | 545–585 | 12 | 212-0545-0000 |

| 630–655 | 625–665 | 12 | 212-0625-0000 |

All values provided by the manufacturer, determined at approx. 20 °C. Subject to technical changes without notice.