NORRES CLAMP 216

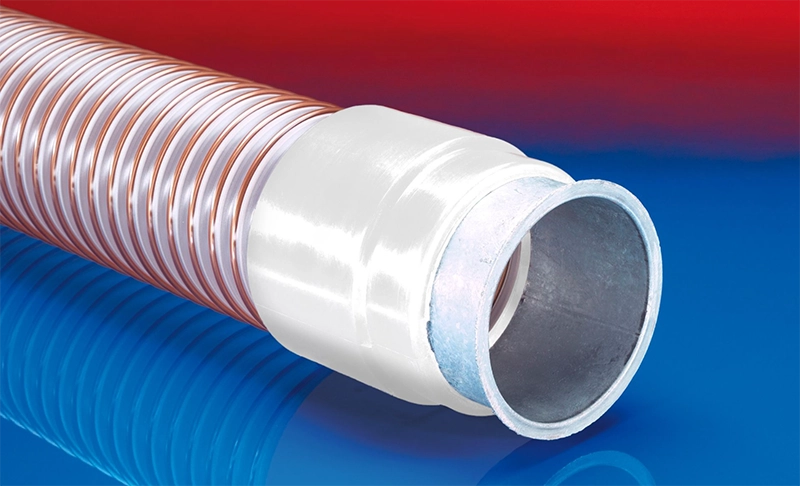

Watertight clamp for heavy, externally corrugated hoses

The NORRES CLAMP 216 is a specially designed hose clamp that ensures a tight and tensile connection even at very low overpressure. The unique spiral geometry allows the clamp to compress precisely around the hose profile, creating a nearly watertight seal. CLAMP 216 is ideal for heavy-duty AIRDUC® and PROTAPE® hoses used in industrial vacuum and transport systems where tightness and durability are critical.

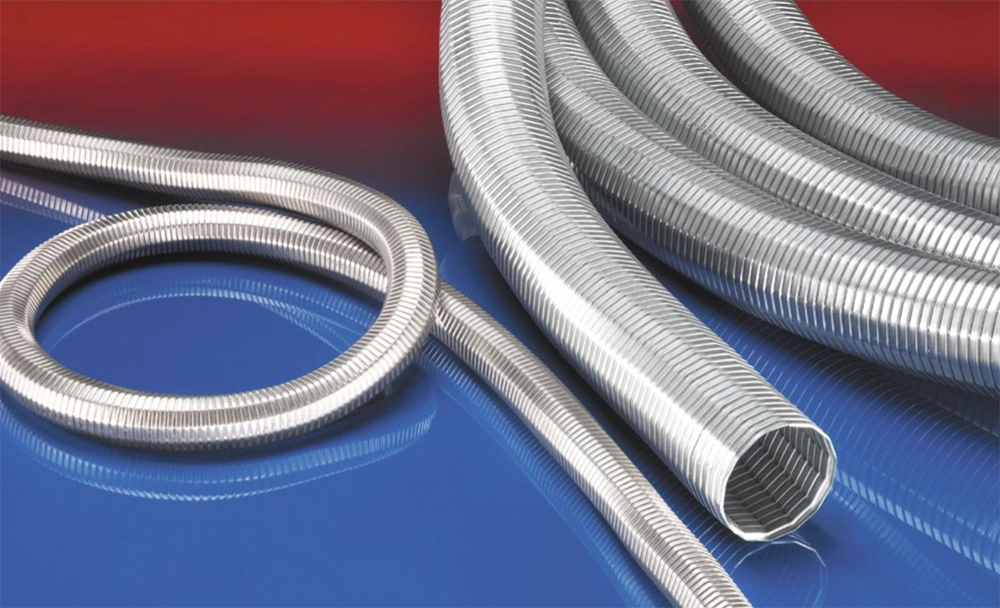

Properties and construction

- Watertight and tensile connection at low overpressure.

- Easy and quick installation – reusable.

- Materials (W2):

- Clamp strip: stainless steel 1.4016 (AISI 430)

- Clamp wire: stainless steel 1.4310 (AISI 301 INOX)

- Screw: chromated steel

- Body: stainless steel 1.4016 (AISI 430)

- Complies with RoHS Directive and REACH Regulation.

Applications

For tight and secure attachment of heavy spiral hoses in suction, pressure, and liquid transport systems – particularly for AIRDUC® 345, 355 and 356 series. Suitable for demanding industrial installations requiring moisture resistance or pressure retention.

Technical note

When selecting clamps for spiral hoses, both mechanical fixation and tightness must be ensured. CLAMP 216 is characterized by its double-wire design, distributing the pressure evenly around the hose. In ATEX environments, CLAMP 212 or 208 is preferred to ensure electrical continuity, while CLAMP 216 is mainly used in non-conductive applications where tightness is the primary concern.

Recommended accessories

- CONNECT 228 / 233 – adapter and coupling parts for AIRDUC® / PROTAPE®.

- CONNECT 270 – 271 – stainless couplings for process and food industry applications.

Need help choosing the right clamp?

Contact us for guidance on proper assembly, sealing and compatibility with your NORRES hoses.

FAQ: NORRES CLAMP 216

What is the NORRES CLAMP 216 used for?

For tight and secure fastening of heavy externally corrugated spiral hoses, especially in the AIRDUC® 345/355/356 series.

Is the CLAMP 216 watertight?

Yes – its construction provides a nearly watertight and tensile seal even at low overpressure.

Which materials are used?

Clamp strip and body: stainless steel 1.4016 (AISI 430).

Clamp wire: stainless steel 1.4310 (AISI 301 INOX).

Screw: chromated steel.

Can it be used in ATEX zones?

Not for equipotential bonding – for ATEX installations use CLAMP 212 (W2/W4).

How do I select the right size?

Determine the hose inner or outer diameter and choose the clamp variant covering that range – see the table below.

Related links

Technical specifications – sizes and compatibility

The table lists the available diameters and order numbers for CLAMP 216. Additional sizes available on request.

| Suitable for hose I.D. (mm) | Order No. |

|---|---|

| 32 | 216-0032-2010 |

| 38 | 216-0038-2010 |

| 40 | 216-0040-2010 |

| 45 | 216-0045-2010 |

| 32 | 216-0032-2872 |

| 38 | 216-0038-2872 |

| 40 | 216-0040-2872 |

| 45 | 216-0045-2872 |

| 50 | 216-0050-0000 |

| 55 | 216-0055-0000 |

| 60 | 216-0060-0000 |

| 65 | 216-0065-0000 |

| 70 | 216-0070-0000 |

| 75 | 216-0075-0000 |

| 80 | 216-0080-0000 |

| 90 | 216-0090-0000 |

| 100 | 216-0100-0000 |

| 102 | 216-0102-0000 |

| 110 | 216-0110-0000 |

| 115 | 216-0115-0000 |

| 120 | 216-0120-0000 |

| 125 | 216-0125-0000 |

| 127 | 216-0127-0000 |

| 130 | 216-0130-0000 |

| 140 | 216-0140-0000 |

| 150 | 216-0150-0000 |

| 152 | 216-0152-0000 |

| 160 | 216-0160-0000 |

| 175 | 216-0175-0000 |

| 180 | 216-0180-0000 |

| 200 | 216-0200-0000 |

| 225 | 216-0225-0000 |

| 250 | 216-0250-0000 |

| 300 | 216-0300-0000 |

All values provided by the manufacturer and measured at approx. 20 °C. Subject to technical modifications.