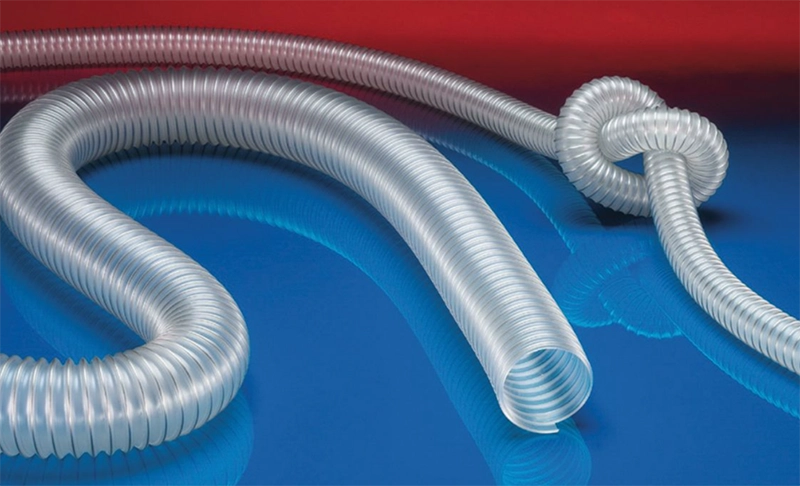

NORRES CP PE 457 EC

Electrically conductive PE hose for ATEX and ventilation – CP PE 457 EC

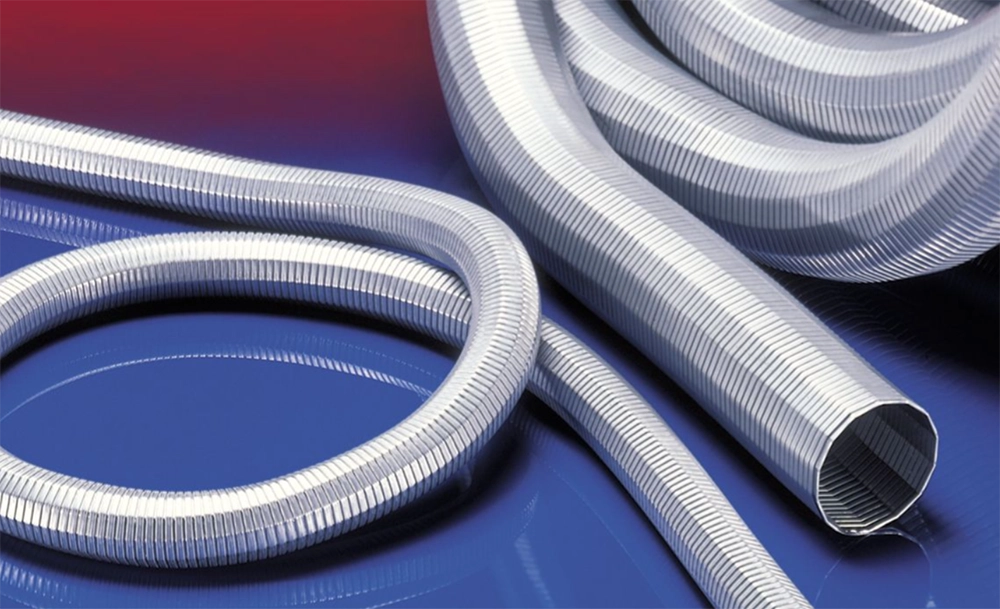

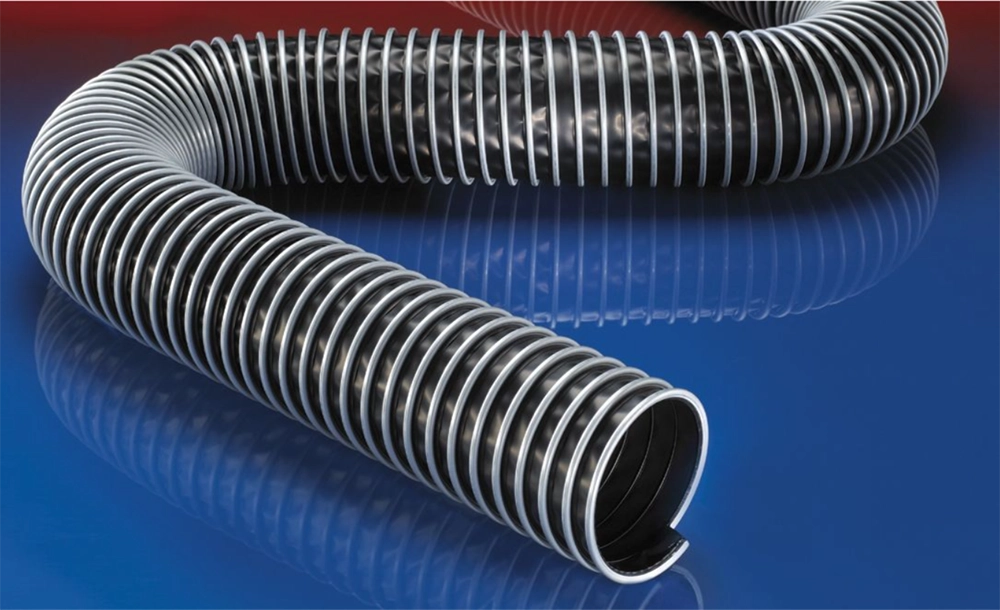

CP PE 457 EC is an extra-flexible, electrically conductive polyethylene hose for ATEX zones and industrial use. The construction with a galvanised steel spiral and conductive wall makes it suitable for ventilation, extraction and transfer of dust, powders, fibres and chemical vapours in potentially explosive atmospheres.

Flexibility and safety for industry

This hose offers compressibility up to 4:1, strong resistance to acids/alkalis and excellent chemical resistance. Temperature range: −35 to +80 °C. Ideal for industrial extraction, chemicals, ventilation and process plants with Zone 22 requirements.

Approved for ATEX zones and ESD control

CP PE 457 EC has electrical and surface resistance <103 Ω and is approved for the aspiration of combustible dust (Zone 22), and for gases and vapours (Zones 0, 1, 2) as well as chemical ventilation. The hose complies with ATEX 2014/34/EU and German TRGS 727.

Need a conductive ventilation hose?

Contact us for technical guidance and correct sizing and ATEX compliance for PE hoses in industrial applications.

Technical note

Construction: Galvanised steel spiral and electrically conductive polyethylene (PE). ATEX approved (<103 Ω), RoHS, REACH. Temperature: −35 °C to +80 °C. Compressibility: 4:1.

FAQ: Conductive PE hose for ATEX

Which environments can it be used in?

Industry, extraction, ATEX Zone 22, chemical ventilation and process plants with explosion risk.

Is it chemical resistant?

Yes, the hose provides very high chemical resistance.

Is the hose approved for ATEX and ESD?

Yes, CP PE 457 EC meets the requirements for conductive ventilation hoses in ATEX and ESD environments (Zones 0, 1, 2, 22).

Related links

Technical specifications

| Inner diameter (mm) | Outer diameter (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Lengths (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 50–51 | 62.00 | 0.490 | 0.270 | 18.00 | 0.60 | 6 | 457-0050-1003 |

| 55 | 67.00 | 0.460 | 0.250 | 20.00 | 0.65 | 6 | 457-0055-1003 |

| 60 | 72.00 | 0.440 | 0.220 | 20.00 | 0.70 | 6 | 457-0060-1003 |

| 63–65 | 77.00 | 0.420 | 0.200 | 22.00 | 0.76 | 6 | 457-0065-1003 |

| 70 | 82.00 | 0.400 | 0.180 | 22.00 | 0.81 | 6 | 457-0070-1003 |

| 75–76 | 87.00 | 0.380 | 0.160 | 24.00 | 0.86 | 6 | 457-0075-1003 |

| 80 | 92.00 | 0.365 | 0.140 | 24.00 | 0.92 | 6 | 457-0080-1003 |

| 89–90 | 102.00 | 0.340 | 0.100 | 26.00 | 1.02 | 6 | 457-0090-1003 |

| 100–102 | 112.00 | 0.225 | 0.085 | 28.00 | 0.82 | 6 | 457-0100-1003 |

| 110 | 122.00 | 0.210 | 0.075 | 30.00 | 0.90 | 6 | 457-0110-1003 |

| 114–115 | 127.00 | 0.205 | 0.070 | 32.00 | 0.94 | 6 | 457-0115-1003 |

| 120 | 132.00 | 0.200 | 0.065 | 32.00 | 0.98 | 6 | 457-0120-1003 |

| 125–127 | 137.00 | 0.195 | 0.060 | 34.00 | 1.00 | 6 | 457-0125-1003 |

| 150–152 | 162.00 | 0.120 | 0.035 | 38.00 | 0.82 | 6 | 457-0150-1003 |

| 160 | 172.00 | 0.115 | 0.030 | 40.00 | 0.84 | 6 | 457-0160-1003 |

| 178–180 | 192.00 | 0.110 | 0.025 | 44.00 | 0.94 | 6 | 457-0180-1003 |

| 200–203 | 212.00 | 0.100 | 0.020 | 48.00 | 0.80 | 6 | 457-0200-1003 |

| 250 | 262.00 | 0.070 | 0.015 | 58.00 | 0.99 | 6 | 457-0250-1003 |

| 254 | 266.00 | 0.065 | 0.015 | 59.00 | 1.01 | 6 | 457-0254-1003 |

| 300 | 312.00 | 0.060 | 0.010 | 68.00 | 1.18 | 6 | 457-0300-1003 |

| 305 | 317.00 | 0.055 | 0.010 | 69.00 | 1.21 | 6 | 457-0305-1003 |

| 315 | 327.00 | 0.050 | 0.010 | 71.00 | 1.25 | 6 | 457-0315-1003 |

| 350 | 362.00 | 0.045 | 0.010 | 78.00 | 1.38 | 6 | 457-0350-1003 |

| 356 | 368.00 | 0.040 | 0.010 | 79.00 | 1.41 | 6 | 457-0356-1003 |

| 400 | 412.00 | 0.040 | 0.005 | 88.00 | 1.57 | 6 | 457-0400-1003 |

| 405–406 | 418.00 | 0.035 | 0.005 | 89.00 | 1.60 | 6 | 457-0406-1003 |

| 450 | 462.00 | 0.035 | 0.005 | 98.00 | 1.77 | 6 | 457-0450-1003 |

| 600 | 612.00 | 0.025 | 0.005 | 128.00 | 2.36 | 6 | 457-0600-1003 |

| 800 | 812.00 | 0.015 | 0.001 | 168.00 | 3.12 | 6 | 457-0800-1003 |

If the required dimensions are only listed as “production length”, the minimum order quantity is 150 metres per order.

Positive and negative pressure values are recommended operating limits. Bending radius is measured on the inside of the hose bend. Subject to technical changes. All values determined at 20 °C and are approximate.