NORRES METAL HOSE 375

Electrically conductive metal hose for ATEX and high-temperature applications – NORRES METAL HOSE 375

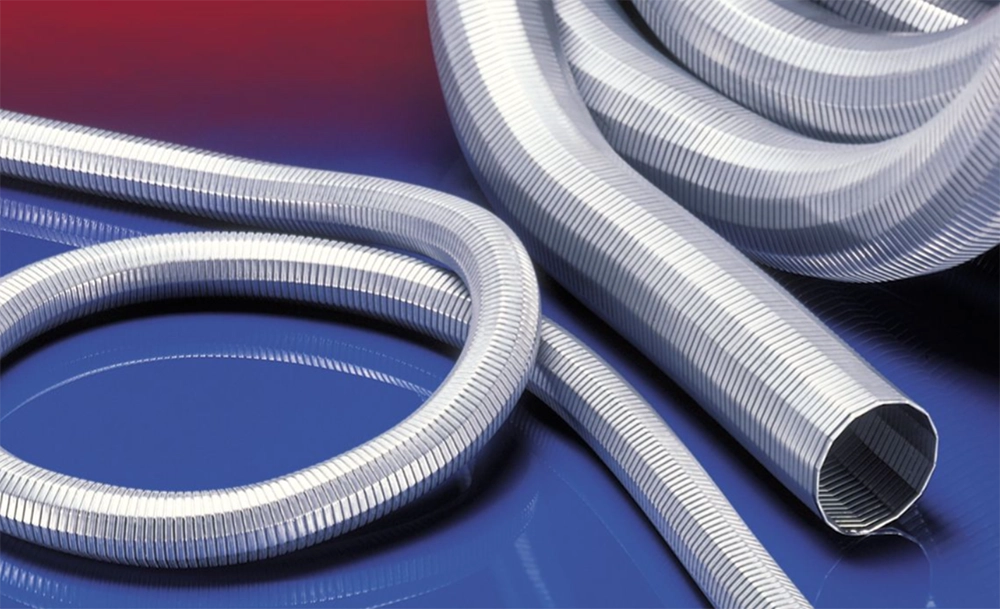

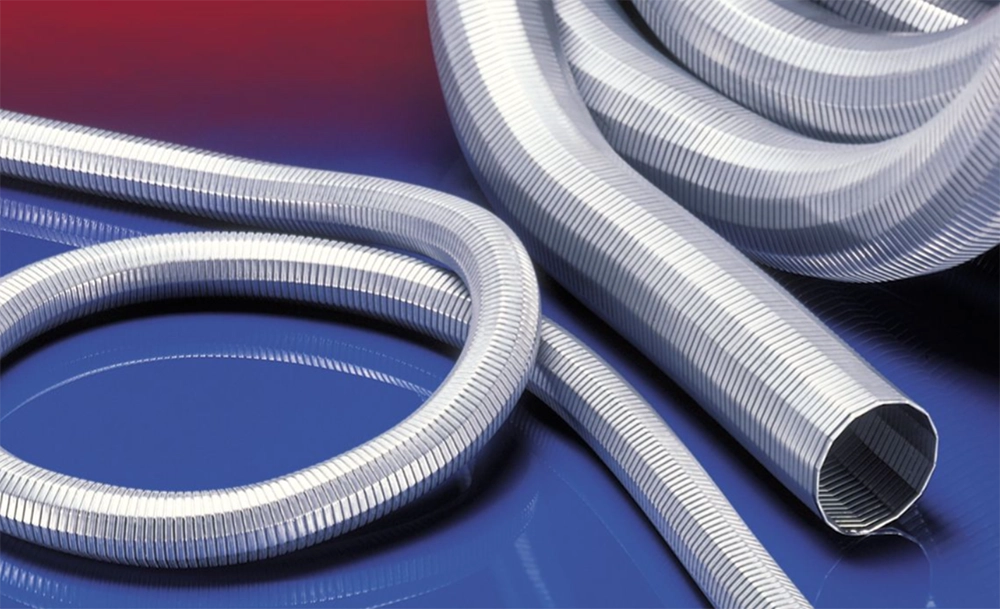

The METAL HOSE 375 from NORRES is a flexible galvanized steel hose designed for demanding industrial applications where high mechanical strength, robustness and electrical conductivity are required.

It is ideal for the transport and extraction of large volumes of abrasive materials, granules, powders and gases – for example, from industrial furnaces, paper and wood processing, filter and dedusting systems, as well as smelting and chemical processes.

High temperature and ATEX approval

The hose is approved for use in ATEX zones 20, 21 and 22 (internal), features extreme abrasion resistance and withstands continuous temperatures up to 120 °C.

The wall and profile are fully conductive (surface resistance < 10³ Ω), in full compliance with ATEX 2014/34/EU and TRGS 727.

Construction and variants

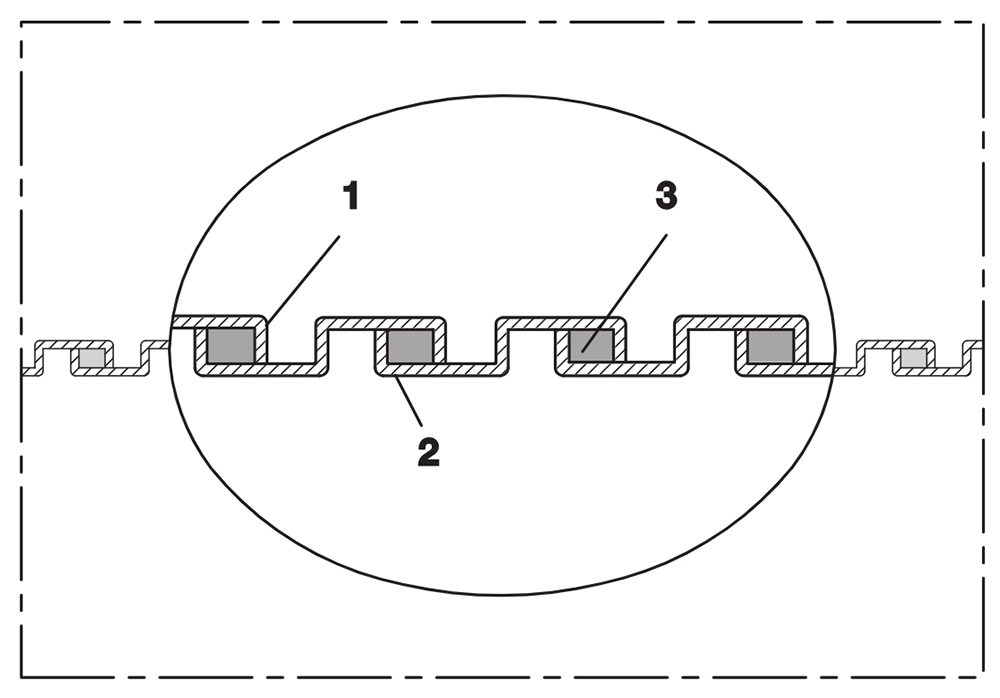

Constructed from profiled, galvanized steel strip with special fibre sealing for a tight and flexible joint.

Available with or without additional rubber sealing and in a wide range of dimensions (20–300 mm inner diameter).

Need to extract hot, abrasive materials or gases?

Contact us for technical advice and configuration of ATEX metal hoses for your specific process, steel or energy application.

Technical note

Construction: Profiled, galvanized steel strip with hook-seam joint and fibre or rubber seal.

Electrically conductive. Temperature resistance up to 120 °C. Available in many lengths and diameters upon request.

FAQ: Electrically conductive metal hose

For which materials and media?

Ideal for dust, granules, chips, gases, oil vapours and aggressive atmospheres in industrial environments.

ATEX approval?

Yes, conductivity < 10³ Ω and approved for ATEX zones 20, 21 and 22 (internal environment, e.g. filter, silo, cyclone, deduster).

Typical applications?

Wood and paper industry, metal and glass works, furnace extraction, oil and chemical industry, machine exhaust systems.

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Bending radius (mm) | Weight (kg/m) | Lengths (m) | Order No. |

|---|---|---|---|---|---|

| 20 | 24.00 | 90.00 | 0.34 | 2.5, 5, 10 | 375-0020-0000 |

| 25 | 29.00 | 98.00 | 0.42 | 2.5, 5, 10 | 375-0025-0000 |

| 30 | 34.00 | 115.00 | 0.50 | 2.5, 5, 10 | 375-0030-0000 |

| 32 | 36.00 | 124.00 | 0.53 | 2.5, 5, 10 | 375-0032-0000 |

| 35 | 39.00 | 133.00 | 0.58 | 2.5, 5, 10 | 375-0035-0000 |

| 38 | 42.00 | 136.00 | 0.63 | 2.5, 5, 10 | 375-0038-0000 |

| 40 | 45.00 | 135.00 | 0.70 | 2.5, 5, 10 | 375-0040-0000 |

| 44–45 | 50.00 | 143.00 | 0.74 | 2.5, 5, 10 | 375-0045-0000 |

| 50–51 | 55.00 | 155.00 | 0.81 | 2.5, 5, 10 | 375-0050-0000 |

| 55 | 60.00 | 173.00 | 0.90 | 2.5, 5, 10 | 375-0055-0000 |

| 60 | 66.00 | 185.00 | 1.01 | 2.5, 5, 10 | 375-0060-0000 |

| 63–65 | 71.00 | 198.00 | 1.09 | 2.5, 5, 10 | 375-0065-0000 |

| 70 | 76.00 | 205.00 | 1.17 | 2.5, 5, 10 | 375-0070-0000 |

| 75–76 | 81.00 | 218.00 | 1.25 | 2.5, 5, 10 | 375-0075-0000 |

| 80 | 86.00 | 230.00 | 1.33 | 2.5, 5, 10 | 375-0080-0000 |

| 89–90 | 97.00 | 235.00 | 1.78 | 2.5, 5, 10 | 375-0090-0000 |

| 100–102 | 107.00 | 250.00 | 1.98 | 2.5, 5, 10 | 375-0100-0000 |

| 110 | 117.00 | 275.00 | 2.17 | 2.5, 5, 10 | 375-0110-0000 |

| 120 | 127.00 | 320.00 | 2.36 | 2.5, 5, 10 | 375-0120-0000 |

| 125–127 | 132.00 | 338.00 | 2.45 | 2.5, 5, 10 | 375-0125-0000 |

| 130 | 139.00 | 345.00 | 2.86 | 2.5, 5, 10 | 375-0130-0000 |

| 140 | 149.00 | 360.00 | 3.07 | 2.5, 5, 10 | 375-0140-0000 |

| 150–152 | 159.00 | 385.00 | 3.29 | 2.5, 5, 10 | 375-0150-0000 |

| 160 | 169.00 | 410.00 | 3.50 | 2.5, 5, 10 | 375-0160-0000 |

| 170 | 179.00 | 435.00 | 3.72 | 2.5, 5, 10 | 375-0170-0000 |

| 178–180 | 189.00 | 455.00 | 3.93 | 2.5, 5, 10 | 375-0180-0000 |

| 200–203 | 211.00 | 460.00 | 5.22 | 2.5, 5, 10 | 375-0200-0000 |

| 225 | 236.00 | 518.00 | 5.86 | 2.5, 5, 10 | 375-0225-0000 |

| 250 | 261.00 | 575.00 | 6.50 | 2.5, 5 | 375-0250-0000 |

| 275 | 286.00 | 633.00 | 7.13 | 2.5, 5 | 375-0275-0000 |

| 300 | 311.00 | 700.00 | 7.78 | 2.5, 5 | 375-0300-0000 |

Positive and negative pressures are recommended operating limits; higher loads are available on request. Bending radius measured along the inner curve of the hose. Technical data determined at 20 °C – approximate values. We reserve the right to make technical modifications.