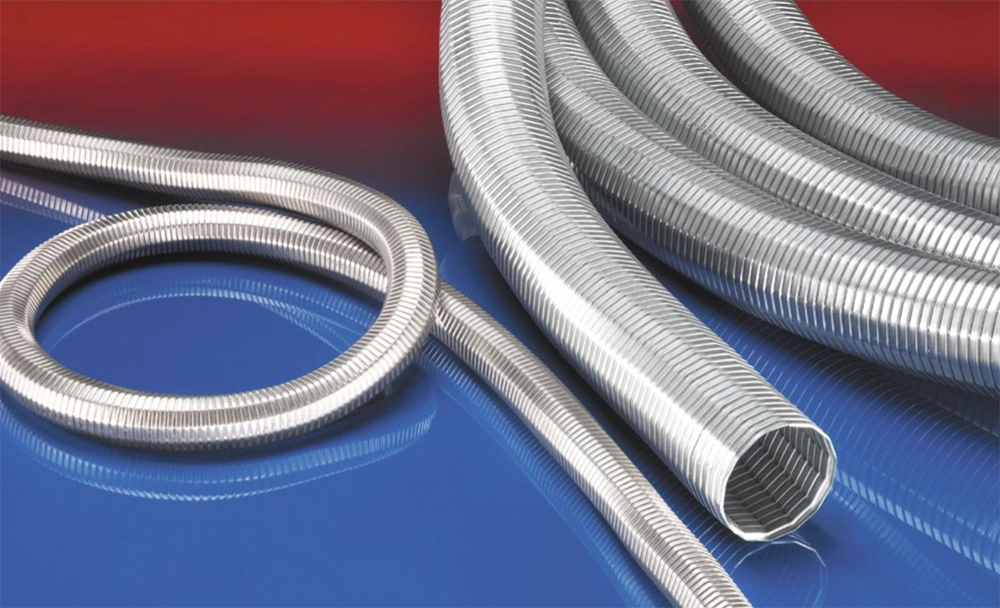

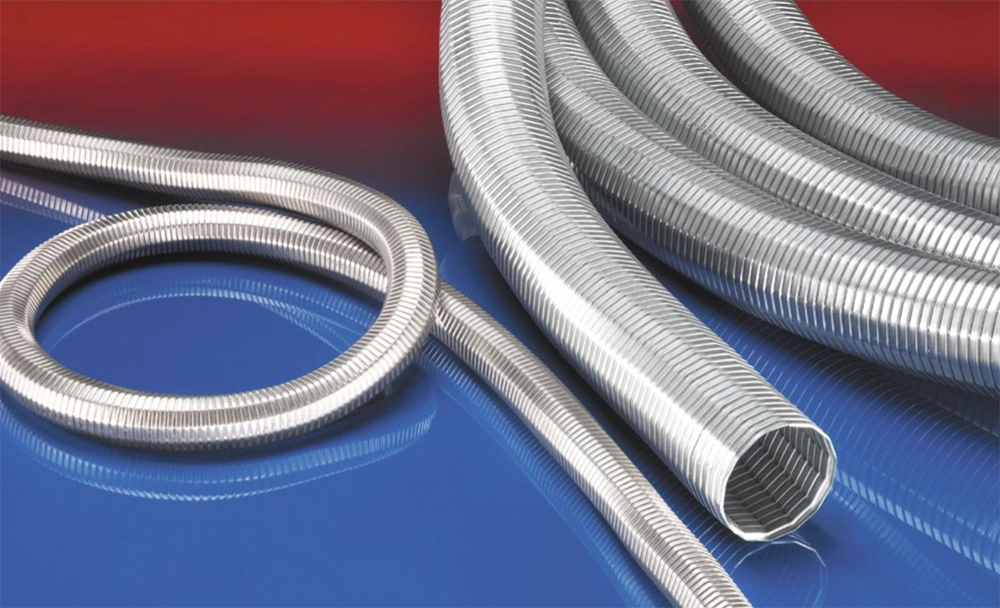

NORRES METAL HOSE INOX 378

Stainless steel hose for high-temperature and chemical applications

The NORRES METAL HOSE INOX 378 is a flexible and robust stainless-steel hose designed for the suction and discharge of gases, vapours, and liquids at high temperatures and under demanding industrial conditions.

Manufactured from high-quality AISI 304 stainless steel, it combines excellent temperature resistance, electrical conductivity, and mechanical strength for safe operation in ATEX-classified zones.

Technical note

The METAL HOSE INOX 378 provides maximum durability in environments where synthetic materials are not suitable.

It is resistant to temperature extremes, mechanical stress, and most solvents and oils.

Thanks to its electrically conductive metal design, it can be safely grounded in ATEX zone 21 / 22 installations to prevent static build-up.

Typical uses include chemical processing, ventilation, exhaust systems, and mechanical engineering.

Need a flexible stainless-steel hose for extreme conditions?

Contact us for advice on metal hoses for exhaust, process and ATEX-classified systems.

Technical specifications

| Material | Stainless steel AISI 304 (1.4301) |

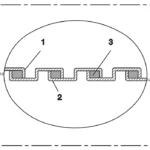

| Construction | Corrugated metal hose with steel braid |

| Temperature range | −270 °C … +600 °C (depending on medium) |

| Pressure range | Up to 16 bar (depending on diameter) |

| Vacuum resistance | 0.9 bar |

| Electrical resistance | Conductive < 10⁶ Ω |

| Bending radius | Depending on size and braid type |

| Colour | Metallic silver |

| Reinforcement | Stainless-steel wire braid |

FAQ: METAL HOSE INOX 378

Which applications is the hose suitable for?

High-temperature transport of gases, vapours and liquids in chemical, mechanical and ventilation systems.

Can it be used in ATEX zones?

Yes – its conductive stainless-steel design makes it suitable for use in ATEX zones 21 and 22.

Is the hose resistant to oils and solvents?

Yes, the metallic construction offers high resistance to oils, solvents and other hydrocarbons.

Which couplings are recommended?

Stainless-steel threaded fittings, flanges or Camlock C/E connectors.

Related links

- ATEX ABC: Before sparks, there are choices

- The invisible weakest link

- Know your Ohm – know your ATEX risk

Recommended accessories

- Stainless-steel safety clamps

- Camlock type C / E connectors

- Custom stainless-steel flanges

Technical specifications

| Inner diameter (mm) | Outer diameter (mm) | Bending radius (mm) | Weight (kg/m) | Length (m) |

|---|---|---|---|---|

| 20 | 24.00 | 90.00 | 0.36 | 10 |

| 25 | 29.00 | 98.00 | 0.44 | 10 |

| 30 | 34.00 | 115.00 | 0.52 | 10 |

| 32 | 36.00 | 124.00 | 0.56 | 10 |

| 35 | 39.00 | 133.00 | 0.60 | 10 |

| 38 | 42.00 | 136.00 | 0.66 | 10 |

| 40 | 45.00 | 135.00 | 0.69 | 10 |

| 44–45 | 50.00 | 143.00 | 0.77 | 10 |

| 50–51 | 55.00 | 155.00 | 0.85 | 10 |

| 55 | 60.00 | 173.00 | 0.94 | 10 |

| 60 | 66.00 | 185.00 | 1.04 | 10 |

| 63–65 | 71.00 | 198.00 | 1.12 | 10 |

| 70 | 76.00 | 205.00 | 1.21 | 10 |

| 75–76 | 81.00 | 218.00 | 1.29 | 10 |

| 80 | 86.00 | 230.00 | 1.38 | 10 |

| 89–90 | 97.00 | 235.00 | 1.90 | 10 |

| 100–102 | 107.00 | 250.00 | 2.11 | 10 |

| 110 | 117.00 | 275.00 | 2.32 | 10 |

| 120 | 127.00 | 320.00 | 2.52 | 10 |

| 125–127 | 132.00 | 338.00 | 2.62 | 10 |

| 130 | 139.00 | 345.00 | 3.02 | 10 |

| 140 | 149.00 | 360.00 | 3.22 | 10 |

| 150–152 | 159.00 | 385.00 | 3.44 | 10 |

| 160 | 169.00 | 410.00 | 3.65 | 10 |

| 170 | 179.00 | 435.00 | 3.80 | 5, 10 |

| 178–180 | 189.00 | 455.00 | 4.10 | 5, 10 |

| 200–203 | 211.00 | 460.00 | 5.60 | 5, 10 |

| 225 | 236.00 | 518.00 | 6.27 | 5 |

| 250 | 261.00 | 575.00 | 6.95 | 5 |

| 275 | 286.00 | 633.00 | 7.63 | 5 |

| 300 | 311.00 | 700.00 | 8.31 | 5 |

Positive and negative pressures are recommended operating limits. The bending radius is measured along the inner curve of the hose. Technical data refer to 20 °C and are approximate values. We reserve the right to make technical modifications.