NORRES PROTAPE® PUR 330 AS BLACK (LD)

Antistatic black PUR hose for dust, gas and process extraction

NORRES PROTAPE® PUR 330 AS BLACK (LD) is a lightweight, reinforced and antistatic polyurethane hose designed for the transport and extraction of gases, dust, fibres and powders in explosive or industrial environments. The black colour protects against light and provides a robust exterior, ideal for installations and machinery where transparency is not required.

Performance and applications

The hose is used in process and ventilation systems, filter and extraction units, surface treatment equipment, blasting systems and dust collection machines. It is resistant to oil, fuel and chemicals and remains highly flexible at low temperatures (down to −40 °C).

Antistatic according to ISO 8031 and TRGS 727 with electrical resistance < 10⁹ Ω. Suitable for ATEX zone 22 (dust inside) and zones 1/2 (gases and liquids).

Temperature range: −40 °C to +90 °C (short-term +125 °C).

Certifications and construction

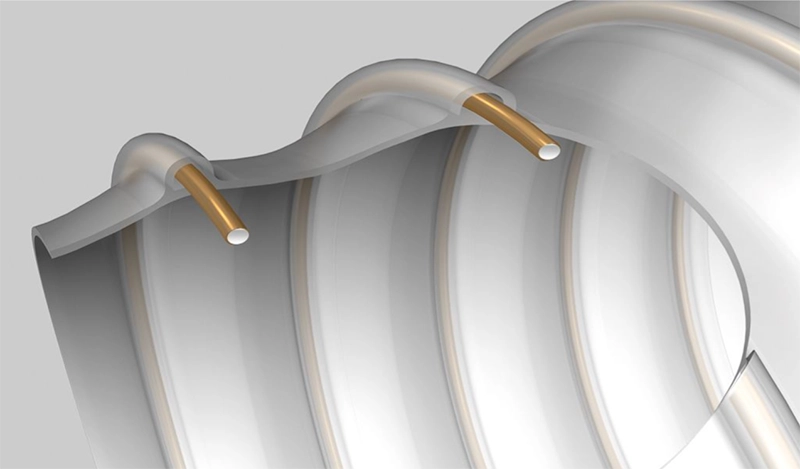

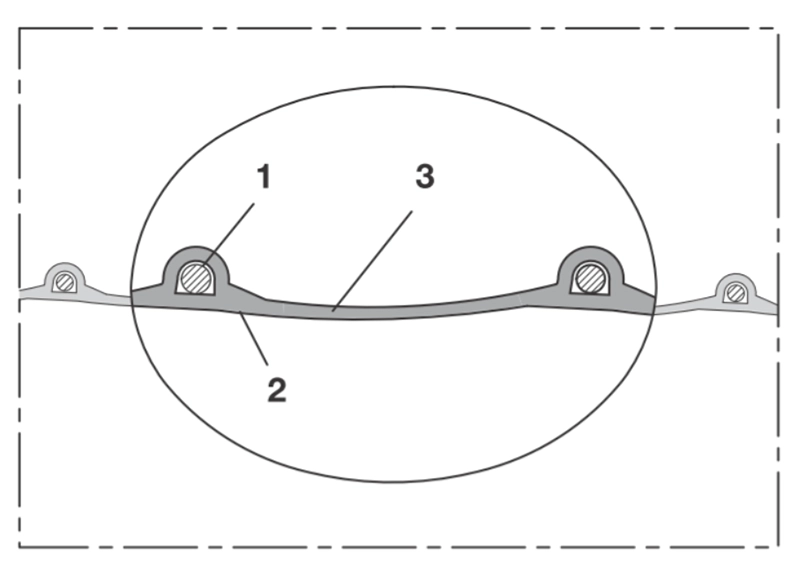

PROTAPE® PUR 330 AS BLACK (LD) is a tape hose with built-in spring steel wire (1), antistatic PUR wall (2) and an abrasion-resistant outer layer (3) made of premium ester-based polyurethane (Pre-PUR®).

Complies with ATEX 2014/34/EU, TRGS 727, RoHS, REACH and ISO 8031.

Available in multiple diameters and lengths, also with optional customised colour or logo printing.

Need technical guidance on ATEX hoses?

Contact us for expert advice on selecting conductive hoses for dust extraction, ventilation and chemical process systems in ATEX zones.

FAQ: NORRES PROTAPE® PUR 330 AS BLACK (LD)

What is the hose used for?

For the extraction of dust, oil and chemical vapours and fine particles in ATEX zones and industrial process systems.

How does it differ from the transparent version?

The BLACK version is opaque, UV-resistant and ideal for use where light protection or visual control of the medium is not necessary.

Is the hose ATEX approved?

Yes – it is permanently antistatic and certified according to ATEX 2014/34/EU and TRGS 727. Suitable for zone 22 (dust) and zones 1/2 (gases and liquids).

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Length (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 40 | 47.0 | 1.02 | 0.34 | 27 | 0.23 | 10 | 330-0040-3030 |

| 50–51 | 58.0 | 0.82 | 0.22 | 33 | 0.37 | 10 | 330-0050-3030 |

| 60 | 68.0 | 0.69 | 0.18 | 38 | 0.43 | 10 | 330-0060-3030 |

| 75–76 | 83.0 | 0.55 | 0.15 | 46 | 0.54 | 10 | 330-0075-3030 |

| 80 | 88.0 | 0.52 | 0.14 | 48 | 0.57 | 10 | 330-0080-3030 |

| 100–102 | 108.0 | 0.42 | 0.08 | 68 | 0.68 | 10 | 330-0100-3030 |

| 120 | 128.0 | 0.35 | 0.07 | 68 | 0.80 | 10 | 330-0120-3030 |

| 125–127 | 133.0 | 0.33 | 0.07 | 71 | 0.84 | 10 | 330-0125-3030 |

| 140 | 148.0 | 0.30 | 0.06 | 78 | 0.84 | 10 | 330-0140-3030 |

| 150–152 | 158.0 | 0.28 | 0.06 | 83 | 1.00 | 10 | 330-0150-3030 |

| 160 | 168.0 | 0.26 | 0.05 | 88 | 1.05 | 10 | 330-0160-3030 |

| 200–203 | 208.0 | 0.21 | 0.03 | 108 | 1.34 | 10 | 330-0200-3030 |

Overpressure and underpressure are recommended threshold operating values. The bending radius is measured through the inside of the hose arch. Subject to technical modifications. All values determined at 20 °C and approximate.