NORRES PROTAPE® PVC 371 AS (HD)

Antistatic PVC ventilation hose with fabric reinforcement – heavy duty

NORRES PROTAPE® PVC 371 AS (HD) is a robust, flexible and antistatic ventilation hose with a fabric-reinforced PVC wall and an integrated spring steel wire. The hose is used for extraction and ventilation of gases, oil mist, spray vapours and chemical fumes in industrial systems where durability and antistatic properties are required.

Applications

Used for conveying gases, oil mist, chemical vapours and fumes in extraction and filtration systems, galvanic plants, paint spray lines and chemical processing facilities. Especially suitable for ATEX environments with requirements for antistatic discharge (Zone 22 inside).

Properties and approvals

- Heavy duty construction with fabric-reinforced PVC wall.

- Permanently antistatic wall in accordance with ISO 8031 – surface resistance <10⁹ Ω.

- Flame-retardant wall according to NF P 92-507 M2.

- Flexible and compressible PROTAPE® design.

- Good chemical resistance – resistant to acids and alkalis.

- Temperature range: −20 °C to +90 °C.

- Complies with RoHS and REACH directives.

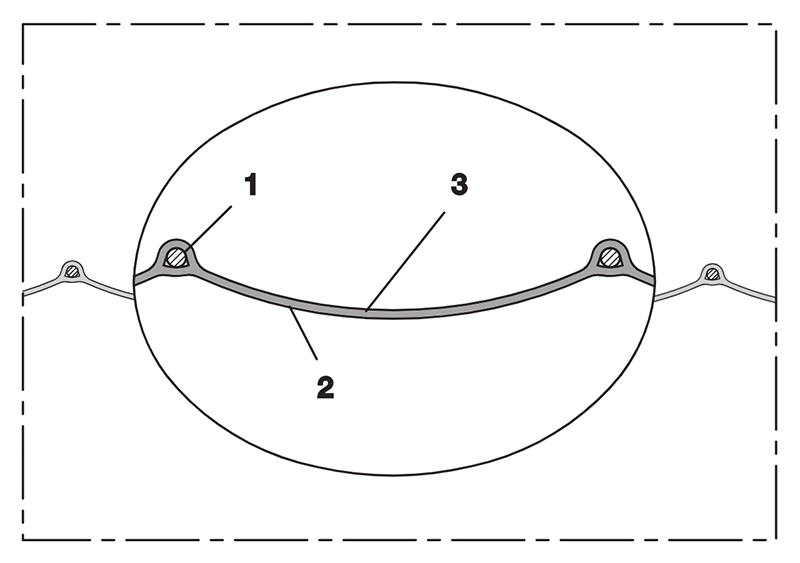

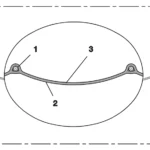

Design

1 = Spring steel wire integrated in wall

2 = PVC coated fabric (reinforced)

3 = Flame-retardant and antistatic PVC wall

Recommended accessories

- CLAMP 208 / 210 / BRIDGE CLAMP – hose clamps in galvanised or stainless steel

- CONNECT 228 / 270–271 – couplings and adapters

Need technical support?

Contact us for professional advice on selection, installation and integration of antistatic and flame-retardant ventilation hoses for ATEX and industrial systems.

FAQ: NORRES PROTAPE® PVC 371 AS (HD)

What is this hose used for?

For extraction of gases, oil mist, chemical vapours and fumes in ventilation and filtration systems.

Is the hose antistatic?

Yes – permanently antistatic wall <10⁹ Ω according to ISO 8031.

Is it flame retardant?

Yes – according to NF P 92-507 M2.

Is it suitable for ATEX zones?

Yes – suitable for ATEX Zone 22 (inside).

What is the temperature range?

From −20 °C to +90 °C.

Related links

Technical specifications

| Inner Ø (mm) | Outer Ø (mm) | Pressure (bar) | Vacuum (bar) | Bending radius (mm) | Weight (kg/m) | Lengths (m) | Order no. |

|---|---|---|---|---|---|---|---|

| 50–51 | 53.30 | 0.41 | 0.18 | 40.8 | 0.39 | 10 / 15 / 20 | 371-0050-3402 |

| 60 | 63.30 | 0.34 | 0.13 | 48.0 | 0.44 | 10 / 15 / 20 | 371-0060-3402 |

| 70 | 73.30 | 0.30 | 0.11 | 56.0 | 0.40 | 10 / 15 / 20 | 371-0070-3402 |

| 75–76 | 78.30 | 0.28 | 0.10 | 60.8 | 0.55 | 10 / 15 / 20 | 371-0075-3402 |

| 80 | 83.30 | 0.26 | 0.10 | 64.0 | 0.59 | 10 / 15 / 20 | 371-0080-3402 |

| 89–90 | 93.30 | 0.23 | 0.09 | 72.0 | 0.65 | 10 / 15 / 20 | 371-0090-3402 |

| 100–102 | 103.70 | 0.21 | 0.06 | 81.6 | 0.66 | 10 / 15 / 20 | 371-0100-3402 |

| 110 | 113.70 | 0.19 | 0.06 | 88.0 | 0.71 | 10 / 15 / 20 | 371-0110-3402 |

| 120 | 123.70 | 0.17 | 0.05 | 96.0 | 0.78 | 10 / 15 / 20 | 371-0120-3402 |

| 125–127 | 128.70 | 0.17 | 0.04 | 101.6 | 0.82 | 10 / 15 / 20 | 371-0125-3402 |

| 150–152 | 153.70 | 0.14 | 0.04 | 121.6 | 1.01 | 10 / 15 / 20 | 371-0150-3402 |

| 200–203 | 204.10 | 0.11 | 0.03 | 162.4 | 1.75 | 10 / 15 / 20 | 371-0200-3402 |

| 300 | 304.10 | 0.07 | 0.01 | 240.0 | 2.25 | 10 / 15 / 20 | 371-0300-3402 |

| 400 | 404.90 | – | 0.01 | 320.0 | 2.72 | 10 | 371-0400-3402 |

| 500 | 504.90 | – | 0.01 | 400.0 | 3.12 | 10 | 371-0500-3402 |

| 600 | 604.90 | – | 0.01 | 480.0 | 4.95 | 10 | 371-0600-3402 |

Pressure and vacuum values are recommended operating limits. The bending radius is measured along the inner curve of the hose. Subject to technical changes. All values determined at approx. 20 °C.