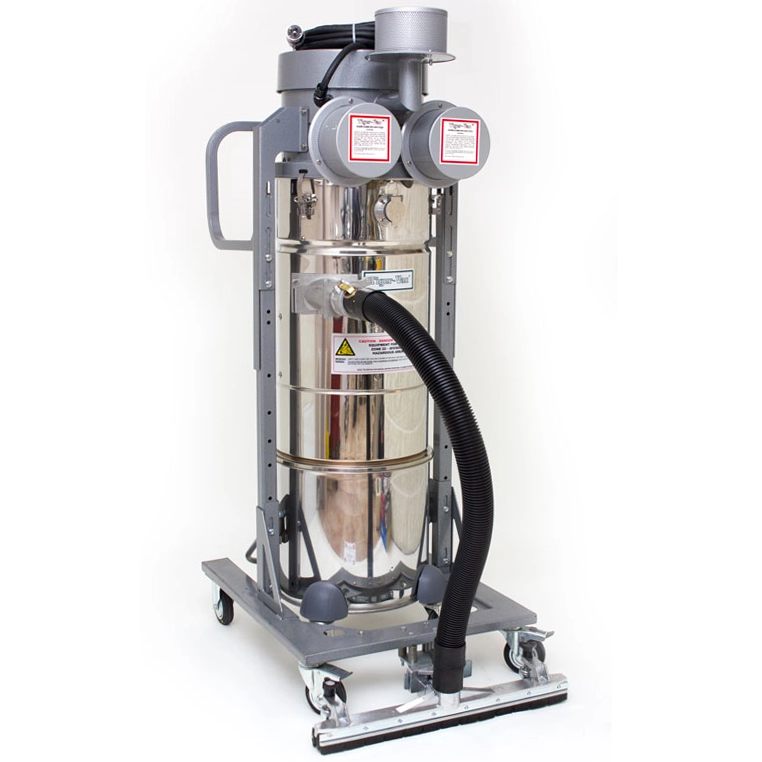

Tiger-Vac 4D-35L EX DT MRP HEPA

ATEX Zone 22 industrial vacuum cleaner with Reverse Purge filtration for the dry recovery of combustible dust

The Tiger-Vac 4D-35L EX DT MRP HEPA is an advanced ATEX II 3D industrial vacuum cleaner designed for the safe and efficient dry recovery of combustible dust in Zone 22 hazardous areas. The MRP version features a Manual Reverse Purge (MRP) filtration system using a static dissipative Conductive Aluminized Spun Bond Reverse Purge Cartridge as the primary filter. Combined with an integrated safety filter and final-stage HEPA H14 filtration, the unit provides exceptional airflow stability, reduced maintenance and maximum filtration efficiency.

- ATEX marking: II 3D – Ex tc IIIB T200°C Dc IP6X.

- Reverse Purge Cartridge as the main SD primary filter (high airflow, low pressure drop).

- HEPA H14 and safety filter provide 99.99% efficiency at 0.3 µm.

- Dual-motor construction for high performance and long operating life.

- Dry Recovery Only — compliant with EN 17348 DT.

- 35 L detachable recovery tank (DT) in stainless steel.

- Complete Ø50 mm static dissipative tool kit included.

Construction and functionality

The 4D-35L EX DT MRP HEPA combines a durable frame, suspended powerhead, large reverse purge cartridge and multi-stage filtration in a compact and service-friendly design. The manual reverse purge system sends a reverse pulse through the cartridge to dislodge dust buildup, ensuring consistent performance even in demanding dust environments.

Safety and ATEX compliance

- Certified for ATEX Zone 22 (II 3D) – suitable for environments with occasional explosive dust atmospheres.

- Internal production control according to ATEX Directive 2014/34/EU Annex VIII.

- Ex tc IIIB T200°C Dc IP6X – resistant to dust ingress and surface temperatures.

- All components are static dissipative and compatible with proper grounding systems.

Applications and industries

Designed for dry recovery of fine and combustible dust in:

- Pharmaceutical and biotech manufacturing

- Food production (flour, sugar, starch, powder ingredients)

- Chemical processing and powder manufacturing

- Plastics and composite industries

- Housekeeping in ATEX Zone 22 environments

Technical note

The Reverse Purge Cartridge provides a large filtration surface area and improved airflow compared to manual shaker systems. The HEPA H14 plus safety filter combination ensures maximum containment of fine dust. This vacuum is dry recovery only and must not be used for liquids. All hoses, wands and tools must be bonded and grounded to maintain ATEX compliance.

Need guidance on ATEX Zone 22 vacuum systems?

We provide support for selecting ATEX-certified equipment and the correct static dissipative accessories for your process.

FAQ

What is the difference between the MRP and MFS versions?

The MRP model uses a Reverse Purge Cartridge that is cleaned using manual reverse pulses, providing better airflow, larger filter surface and more stable performance compared to the MFS shaker system.

Can this vacuum collect liquids?

No. The unit is certified for Dry Recovery Only and must not be used for liquid recovery.

What filtration system does it use?

A Reverse Purge Cartridge (SD) as the primary filter, an integrated safety filter and HEPA H14 final filtration.

Which industries typically use this model?

Pharmaceutical, food production, chemical processing, plastics and composite manufacturing, and Zone 22 housekeeping.

Related links

Technical specifications

| Specification | Data – 4D-35L EX DT MRP HEPA |

|---|---|

| ATEX marking | II 3D – Ex tc IIIB T200°C Dc IP6X |

| Zone classification | Zone 22 (external) |

| Certificates | EU DoC, EN 17348 DT, EN 60079-0, EN 60079-31 |

| Type | Electric – dry recovery only |

| Voltage / Frequency | 240 V / 50 Hz |

| Phase | Single-phase |

| Wattage | 2100 W |

| Amperage | 10 A |

| Motors | Dual Ametek® long-life bypass motors |

| Airflow | 375 m³/h |

| Vacuum pressure | 2180 mm H₂O |

| Suction inlet | Ø50 mm |

| Filter cleaning | Manual Reverse Purge (MRP) |

| Main filter | Reverse Purge Cartridge – Conductive Aluminized Spun Bond |

| Safety filter | Yes – integrated |

| HEPA filters | HEPA H14 – 99.99% at 0.3 μm |

| Recovery tank | 35 L detachable tank (DT) |

| Construction | Stainless steel (AISI 430) |

| Cable length | 10.6 m |

| Dimensions (L × W × H) | 71 × 60 × 161 cm |

| Weight | 59 kg |

| Accessories | Complete Ø50 mm static dissipative tool kit |