Tiger-Vac ATEX-10A (IT-40L) CFE HEPA 2GD PNEUMATISK

Pneumatic inert vacuum cleaner for the safe recovery of metallic dust in ATEX zones

The Tiger-Vac ATEX-10A (IT-40L) CFE HEPA 2GD PNEUMATIC is a compact, air-operated inert vacuum cleaner designed for the safe recovery and neutralisation of combustible and conductive metallic dust in ATEX Zone 1/2/21/22 with an internal Zone 20. The unit uses a water-based Wet Mix immersion system that directs metallic dust into a liquid bath to prevent ignition sources, hotspots and thermal runaway. The system is fully ESD-safe with a total resistance below 10 ohm and built from AISI 304 stainless steel, making it ideal for 3D printing, laboratories, powder metallurgy and other environments handling fine metallic dust.

Water Only – for water-compatible metallic dust only

The ATEX-10A is classified as Water Only and must only be used with water-compatible metals such as non-reactive aluminium, steel, copper, brass, nickel-based alloys and selected 3D printing powders, provided that the SDS confirms “no reaction with water”. Water-reactive metals such as magnesium, lithium, zirconium, pyrophoric titanium AM powders, alkali metals and moisture-sensitive ammunition must never be recovered with this model. Organic dust must not be recovered by any inert vacuum cleaner.

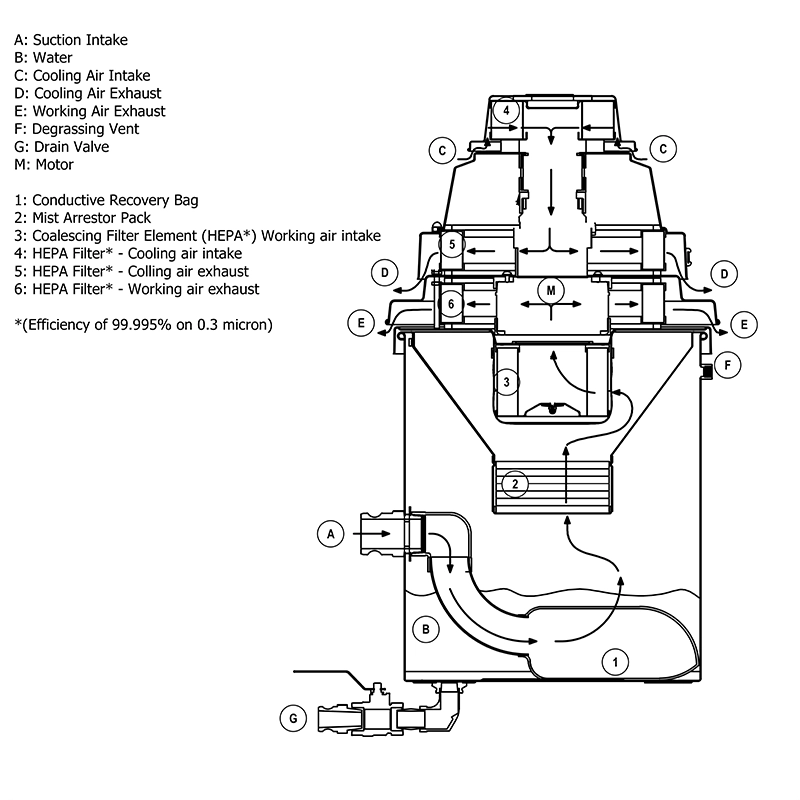

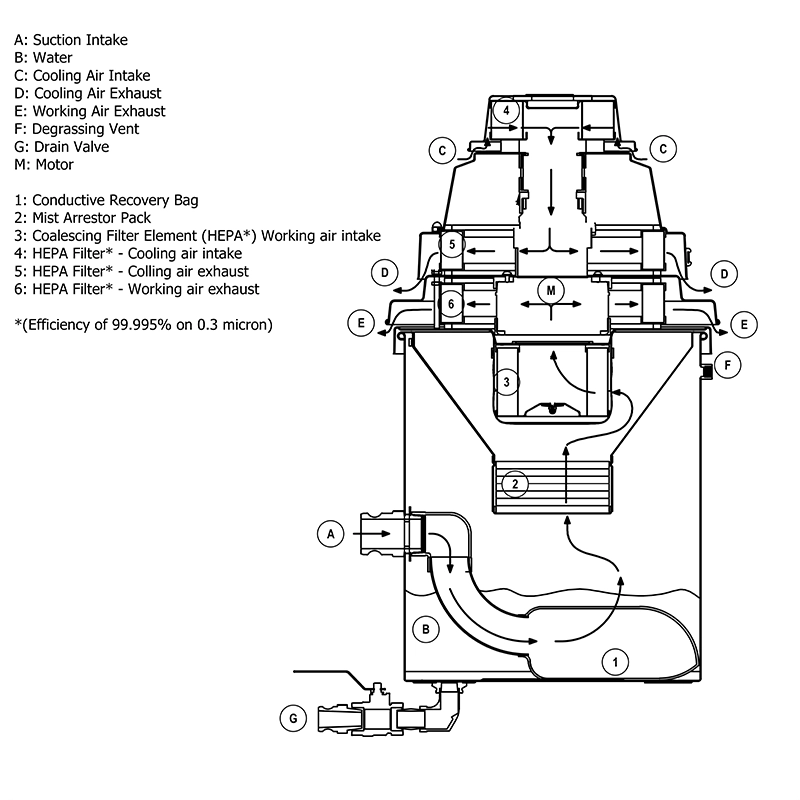

Operating principle – mini immersion separator

Dust and air enter through a 38 mm conductive inlet and are directed into the Wet Mix liquid bath, where approximately 12.3 litres of water immobilise and neutralise the dust inside the conductive wet recovery bag with a capacity of approximately 3 litres. The airflow continues through an upstream HEPA-grade CFE coalescing filter (99.97% at 0.3 µm), removing moisture, aerosols and fine particulates. An integrated degassing vent eliminates trapped gas, and the liquid level can be monitored through a visible level indicator. The tank is emptied safely via the dedicated drain valve.

Construction, materials and components

The recovery tank is made from AISI 304 stainless steel. The coalescing HEPA element filters both moisture and fine dust, and all components—hoses, wheels, tools and fittings—are conductive or static dissipative to prevent electrostatic discharges. The system meets EN 17348 requirements for the recovery of combustible and self-heating metallic dust and functions as a compact Liquid Precipitation Collector according to NFPA 484.

Pneumatic operation – continuous and low-noise

The vacuum operates via a pneumatic Venturi system requiring a compressor of approximately 15 HP, a 0.5" air supply hose and a working pressure of 5.5 bar. The airflow is 187 m³/h at 2790 mm H2O vacuum, with a sound level of only 68 dB(A). As the unit has no electric motor, it can operate continuously without overheating.

Included accessories

The ATEX-10A includes a complete ESD-safe tool kit: 1.5" conductive suction hose (3 m), 0.5" anti-static air hose (7.5 m), two-piece stainless steel wand, universal floor tool with conductive brush strips and rubber blades, conical nozzle, Tiger Claw nozzle, round brush and a multimeter for resistance verification. Conductive wet recovery bags with holder are supplied with the unit.

Typical applications

- 3D printing and additive manufacturing (metal AM)

- Laboratories and R&D handling metallic dust

- Powder metallurgy and precision manufacturing

- Electronics and energy sectors handling conductive particulates

Safety and responsibility

- For metallic, water-compatible dust only

- Only water may be used as the immersion liquid

- Correct liquid level is essential for safe operation

- Accessories are static dissipative but not ATEX type-tested

- The system must be part of a fully bonded and grounded ATEX setup

- The customer must verify SDS documentation

Technical note on inert technology

The ATEX-10A operates as a mini Liquid Precipitation Collector according to NFPA 484. While inertisation greatly reduces risk when handling reactive metallic dusts, it never replaces a full, conservative risk assessment of the process, environment and operating procedures.

Inert or ATEX – do you know the difference?

Inert or ATEX – do you know the difference?

Dry ATEX vacuum cleaners may be insufficient for reactive metallic dust. Read when inertisation is required and when ATEX alone is not enough.

Need advice on inert or ATEX solutions?

Need advice on inert or ATEX solutions?

Contact us for guidance on inertisation, material compatibility and the safe recovery of metallic powders in additive and laboratory environments.

Important ATEX resources

- ATEX ABC – Before sparks, there are choices

- Why EN 17348 matters for metallic dust

- Know your ohm – know your ATEX risk

FAQ

- Which metals can be recovered? Water-compatible metals such as non-reactive aluminium, copper, brass, steel, nickel alloys and selected 3D printing powders.

- Which metals must not be recovered? Magnesium, lithium, zirconium, pyrophoric titanium AM powders, alkali metals and any metal that reacts with water.

- Can I recover organic dust? No, organic dust must never be recovered by an inert vacuum cleaner.

- Are the accessories ATEX-certified? No, accessories are static dissipative but not ATEX type-tested and must be evaluated as part of the complete system.

- How much liquid is required? Approximately 12.3 litres of water, as specified by the manufacturer.

All values are provided by the manufacturer at approximately 20 °C. Technical changes reserved.

| Model Name | ATEX-10A (IT-40L) CFE HEPA |

| ATEX Classification | II 2GD Ex h IIC T6 Gb / Ex h IIIC T85 °C Db |

| Application | Pneumatic inert vacuum cleaner with Water Only Wet Mix immersion system |

| Type | Pneumatic, single Venturi |

| Minimum Compressor Size | Approx. 15 HP |

| Air Supply Hose | 0.5" (12.7 mm) |

| Input Air Volume | 16.5–21.2 L/s |

| Input Air Pressure | 5.5 bar |

| Airflow | 187 m³/h |

| Vacuum Pressure | 2790 mm H₂O |

| Sound Level | 68 dB(A) |

| Suction Inlet | 38 mm |

| Cart Type | 4-wheel dolly (4W) |

| Filtration | Upstream HEPA-grade CFE coalescing filter |

| HEPA Efficiency | 99.97% at 0.3 µm |

| Tank Material | AISI 304 stainless steel |

| Liquid Capacity | Approx. 12.3 L water |

| Recovery Bag Capacity | Approx. 3 L |

| Liquid Type | Water only |

| Degassing | Integrated degassing vent |

| Level Indicator | Yes |

| Total Resistance | < 10 ohm (ESD safe) |

| Length | 48 cm |

| Width | 46 cm |

| Height | 86 cm |

| Included Hoses | 1.5" conductive suction hose (3 m) + 0.5" air hose (7.5 m) |

| Included Tools | Stainless steel wand, universal tool, conical nozzle, Tiger Claw, round brush, multimeter |