Tiger-Vac C-10 EX (2+2W) MR

ATEX 1/3D industrial vacuum cleaner for combustible dust in Zone 22 with internal Zone 20

Tiger-Vac C-10 EX (2+2W) MR is a compact and mobile ATEX-certified industrial vacuum cleaner for dry recovery of combustible and conductive dust in areas classified as Zone 22, where a very high level of protection is also required inside the recovery system (Zone 20). The vacuum is IECEx- and ATEX third-party certified by LCIE (0081) as II 1/3D with internal Ex h IIIC T200°C Da and external Ex h tc IIIC T200°C Dc IP6X, and it is tested for combustible dust collection according to EN 17348 DT.

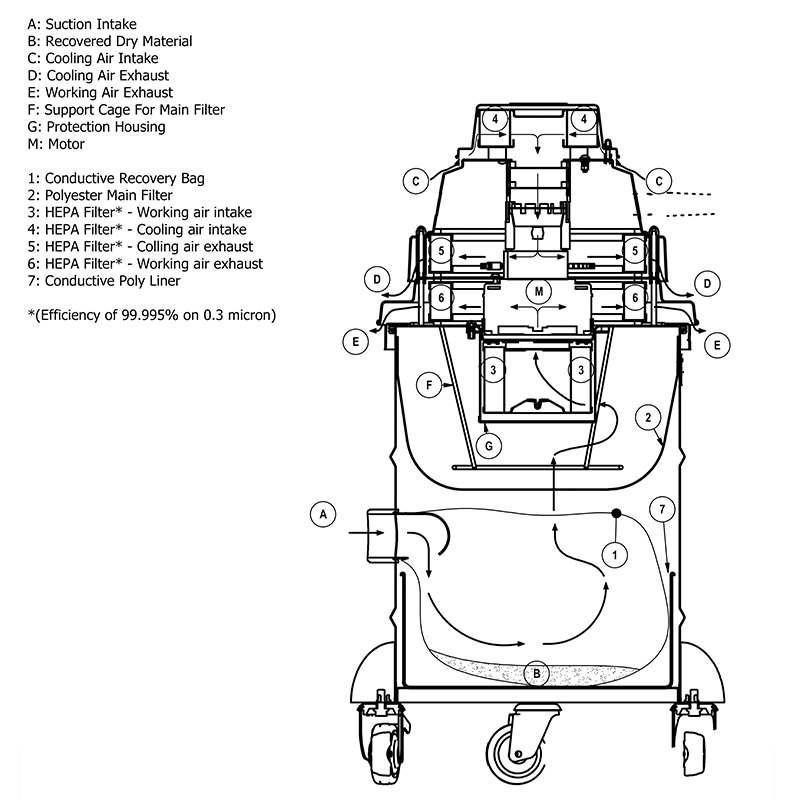

Filtration with 4 HEPA H14 filters and conductive collection bag

The C-10 EX (2+2W) MR features a multi-stage filtration system that combines a large static dissipative main filter with four HEPA H14 filters, each factory tested to 99.99% efficiency at 0.3 µm. The material is collected inside a conductive poly liner bag in the 38 L stainless steel tank, which makes it easy and safe to seal and dispose of dust and powders. The static dissipative filter assembly and accessories help control electrostatic charging and reduce ESD risk in ATEX classified environments.

Technical configuration and motor

The vacuum is equipped with a heavy-duty 2-stage by-pass universal motor rated 1.2 kW (194 m³/h and 2504 mm H₂O) with a sound level of 72 dB(A). An integrated filter blockage indicator light informs the operator when the conductive collection bag is getting full, helping to avoid excessive filter loading and loss of airflow. The recovery tank is made of stainless steel (Type 430 as standard, Type 304 available) and mounted on a robust 2+2 wheel trolley that is easy to manoeuvre in narrow aisles, around process equipment and under pipework.

ATEX, IECEx and EN 17348 certification

Tiger-Vac C-10 EX (2+2W) MR is specifically designed for the recovery of combustible dust in EX classified areas and is certified according to IECEx LCIE 15.0048 as well as LCIE 15 ATEX 3061 and LCIE 19 ATEX 1001 X. This means that both the internal system (tank, air path and filtration) and the external enclosure have been assessed by a notified body according to EN IEC 60079-0, EN 60079-31, EN ISO 80079-36/37 and EN 17348 DT. The vacuum is marked II 1/3D with a dust temperature class up to T200 °C and an ambient temperature range from -5 °C to +37 °C.

Industries and applications

The C-10 EX (2+2W) MR is suitable for general cleaning in production areas where combustible dust is present: food ingredients, sugar, milk powder and starch, pharmaceutical and biotech powder processes, chemical production, plastic and rubber powders, metal and composite dust, 3D printing and additive manufacturing, as well as filling, packaging and storage areas in ATEX Zone 22. The conductive collection bag and ESD-safe tool kit make the unit particularly suitable where the dust is both combustible and potentially conductive.

Standard accessories – static dissipative tool kit

As standard, Tiger-Vac C-10 EX (2+2W) MR is supplied with a complete set of static dissipative tools and filters so the unit can be put directly into service in ATEX environments: conductive suction hose (38 mm × 3 m), chrome curved handle with airflow regulator, two extension wands (32 mm), ESD-safe floor tool with conductive nylon bristles, round brush, crevice tool and upholstery tool. A static dissipative main cloth filter with cage, conductive poly liner collection bag and upstream HEPA filter are also included, as well as a cable holder hook mounted on the powerhead.

Optional accessories and customisation

For more demanding installations the C-10 EX can be configured with optional accessories such as longer static conductive suction hoses (up to 15 m via 50 ft hose), additional cuffs and unions, a double-bend 38 mm wand, larger ESD-safe floor tools and adapters between 38 mm and 32 mm. A high temperature main filter assembly (SD) is also available for applications with higher process temperatures. This makes it possible to adapt the system to different process machines, filling lines or semi-centralised vacuum networks while maintaining the same ATEX and ESD performance level throughout the installation.

Technical note on internal Zone 20 and accessories

Because the C-10 EX (2+2W) MR is certified as II 1/3D, it is approved for the recovery of combustible dust directly into the internal Zone 20 (Da) within the tank and filter housing, while the external parts of the vacuum are suitable for operation in Zone 22 (Dc). To maintain this level of safety, the complete system – hoses, tools, couplings and operator – must form part of a properly bonded and grounded solution. Always use static conductive or static dissipative hoses and tools, ensure effective grounding, and follow ATEX and EN 17348 requirements for testing, documentation and preventive maintenance.

Need advice on ATEX 1/3D vacuum cleaners?

We can help you choose certified equipment, design proper bonding and grounding, and document compliance with EN 17348 and ATEX 2014/34/EU.

FAQ

What does the ATEX marking II 1/3D on the C-10 EX (2+2W) MR mean?

It indicates that the vacuum offers a very high level of protection inside the tank and filter housing (Zone 20 – category 1D) and a high level of protection externally for use in Zone 22 (category 3D). This means it is suitable for the collection of combustible dust, not only for operation in the zone.

How many HEPA filters are fitted and what class are they?

The C-10 EX is supplied with 4 HEPA H14 filters, each tested to 99.99% efficiency at 0.3 µm. Combined with the main filter, this gives a very high filtration level for fine and hazardous dusts.

Which accessories are included as standard?

Standard equipment includes a conductive suction hose, curved handle, extension wands, ESD-safe floor tool, round brush, crevice tool, upholstery tool, static dissipative main cloth filter with cage, conductive poly liner collection bag and an upstream HEPA filter. The unit is therefore ready for use in ATEX environments out of the box.

How does the MR version differ from the C-10 EX (2+2W) MR BLSD?

The MR version is equipped with a robust universal motor with brushes, while the MR BLSD variant uses a brushless motor. Both versions are ATEX 1/3D certified and supplied with 4 HEPA H14 filters, but the BLSD model is optimised for longer motor life.

Can the vacuum be used for all types of combustible dust?

The vacuum is certified for the collection of combustible dust according to EN 17348, but it is always the end user’s responsibility to evaluate the specific dust, process conditions, temperatures and potential health hazards, and to ensure that the complete installation complies with applicable standards and internal company policies.

Related links

Technical specifications – Tiger-Vac C-10 EX (2+2W) MR

| Specification | Data |

|---|---|

| ATEX marking (external) | II 1/3D – Ex h tc IIIC T200°C Dc IP6X |

| ATEX marking (internal) | Ex h IIIC T200°C Da (internal Zone 20) |

| Certification | IECEx LCIE 15.0048, LCIE 15 ATEX 3061, LCIE 19 ATEX 1001 X – third-party certified (LCIE 0081) |

| Zone classification | Internal Zone 20 (Da) / external Zone 22 (Dc) |

| Application | Dry recovery of combustible and conductive dust in ATEX dust atmospheres (Zone 22) |

| Voltage / Frequency | 220–240 V – 50/60 Hz (1~) |

| Phase / Power | Single-phase universal motor – 1.2 kW (1,200 W) |

| Current draw | 5 A |

| Airflow | 194 m³/h |

| Vacuum | 2504 mm H₂O |

| Ambient temperature | -5 °C to +37 °C |

| Sound level | 72 dB(A) |

| Suction inlet | 60 mm |

| Dust recovery tank | 38 L – conductive poly liner bag inside stainless steel tank |

| HEPA filters | 4 × HEPA H14, 99.99% at 0.3 µm, total HEPA surface area approx. 20,253 cm² |

| Main filter | Static dissipative main cloth filter with cage, surface area approx. 3,480 cm² |

| Filter monitoring | Filter blockage indicator light for full bag / restricted airflow |

| Tank material | Stainless steel Type 430 (Type 304 available on request) |

| Trolley | Steel frame with 2+2 wheels, front castors with brakes |

| Dimensions (L × W × H) | 69 × 51 × 119 cm |

| Weight (vacuum only) | 35 kg |

| Power cord length | 10.6 m |

| Standard accessories | Conductive suction hose 1.5" (38 mm) × 3 m, chrome curved handle 38–32 mm, 2 × 32 mm extension wands, ESD-safe 32 mm floor tool with conductive nylon bristles, round brush, crevice tool, upholstery tool, conductive poly liner bag, main cloth filter with cage, upstream HEPA filter |

| Optional accessories (examples) | Static conductive crushproof hose up to 50 ft (15 m), additional hose cuffs and unions, double-bend 38 mm wand, 38 mm ESD floor tool, 38–32 mm reducer, high temperature main filter assembly (SD) |

| Standards | EN 17348 (combustible dust collection), EN IEC 60079-0, EN 60079-31, EN ISO 80079-36/37 |