Tiger-Vac C-10 EX (4W) STAINLESS STEEL ULPA

ATEX-certified cleanroom vacuum cleaner with dual ULPA filtration for combustible and hazardous dust

The Tiger-Vac C-10 EX (4W) STAINLESS STEEL ULPA is a compact, ESD-safe and third-party ATEX certified industrial vacuum cleaner designed for the safe recovery of combustible, toxic and fine dusts in environments with extremely high requirements for cleanliness and operational safety. Its internal classification of Zone 20 (Da) and external classification of Zone 22 (Dc) allows direct recovery of combustible dust inside the filtration and collection chamber, while the dual ULPA U15 filtration system (for both working air and motor cooling/exhaust air) ensures suitability for contamination-controlled environments such as ISO 4–7 cleanrooms, pharmaceutical production, biotech facilities and laboratories.

- ATEX third-party certification: II 1/3D – LCIE 15 ATEX 3061.

- Internal Zone 20 (Da) / external Zone 22 (Dc).

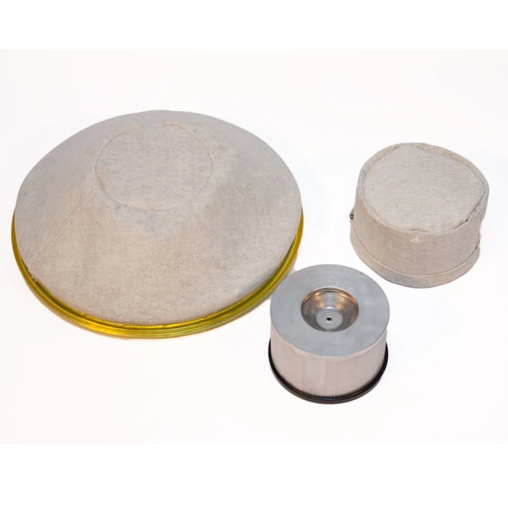

- 5-stage filtration system with dual ULPA U15 filters (working air + cooling/exhaust air), safety filter and main filter.

- Autoclavable 19 L recovery tank made of electropolished AISI 316 stainless steel.

- Heavy-duty 2-stage by-pass motor (1200 W).

- ESD-safe accessories and conductive recovery bags included as standard.

- Equipped with a filter blockage indicator light that alerts the operator when the recovery bag is full.

Why internal Zone 20 and external Zone 22 matter

When a vacuum cleaner is certified for internal Zone 20, the entire internal air path — including the filter chamber, primary filter, ULPA filter and collection tank — is approved for direct handling of combustible dust. The external Zone 22 classification allows operation in areas where explosive dust may be present occasionally. The 1/3D (Da/Dc) configuration is highly valued in pharmaceutical and biotech applications where both product integrity and operator safety are critical.

Ideal for pharmaceutical, biotech, laboratory and food production environments

The unit is constructed with an electropolished AISI 316 stainless steel tank and an AISI 304 stainless steel powerhead, and comes equipped with conductive recovery bags, dual ULPA filtration and autoclavable components. The combination of antistatic design, U15 filtration, ESD-safe accessories and third-party ATEX certification makes the vacuum ideal for GMP areas, cleanrooms, API handling, powder processing and hygiene-critical environments in the food industry. The integrated blockage indicator enhances process safety by ensuring timely bag and filter replacement.

Standard accessories (included)

- 19 L autoclavable AISI 316 stainless steel recovery tank.

- Dual ULPA U15 filtration (working air + cooling/exhaust air), safety filter and ESD-safe main filter.

- Conductive recovery bags.

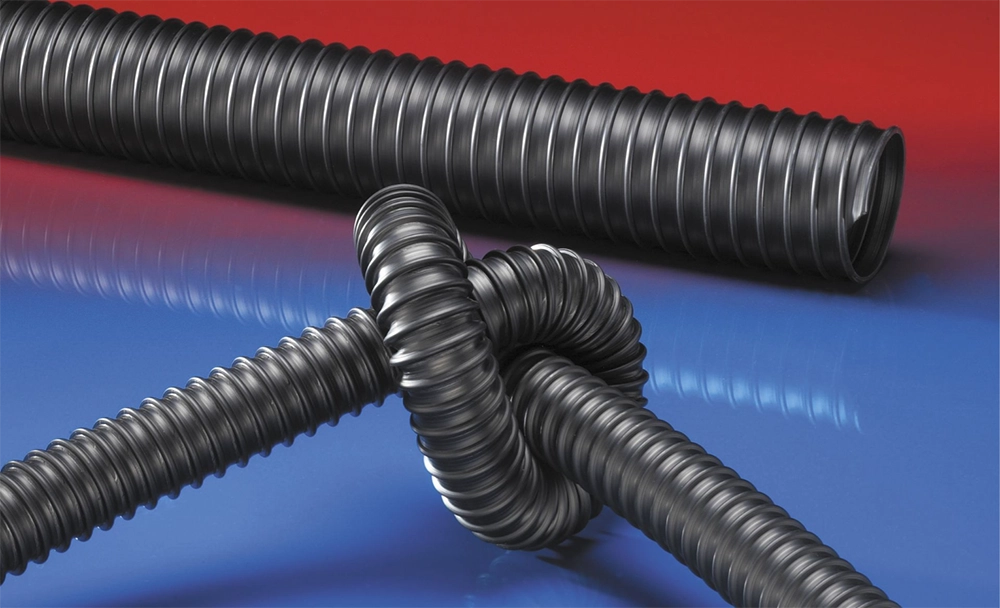

- CWR EX accessory kit (hose, extension wands, floor tool, crevice tool, etc.).

Options (available separately)

- Middle Ring with Activated Carbon (MRAC) for adsorption of fumes and vapours.

- Foodgrade suction hose 1.25" (32 mm) × 3 m.

- EPDM autoclavable suction hose 1.25" (32 mm) × 3 m with stainless steel camlock.

- Needle Trap (electropolished stainless steel).

Need guidance on ATEX for cleanrooms?

We can help you choose ATEX and ULPA-certified vacuum systems for pharmaceutical, biotech, food and laboratory environments.

FAQ

What does ATEX II 1/3D (Da/Dc) mean?

The unit is certified for internal Zone 20 (Da), allowing direct collection of combustible dust, while the exterior is classified for Zone 22 (Dc), meaning it may be used in areas with occasional presence of explosive dust.

Is it suitable for cleanrooms?

Yes. The dual ULPA U15 filtration system and autoclavable tank make it suitable for ISO 4–7 cleanrooms, pharmaceutical production, API handling and laboratories.

Can I use standard vacuum hoses?

No. Only static dissipative / ESD-safe hoses and accessories must be used to maintain ATEX-compliant grounding resistance.

What filters does the unit use?

It features a static dissipative main filter, a safety filter and dual ULPA U15 filters for capturing extremely fine and hazardous dusts.

Related links

Technical specifications

| Specification | Data |

|---|---|

| ATEX marking (Int/Ext) | II 1/3D – Ex h IIIC T200°C Da / Ex h tc IIIC T200°C Dc IP6X |

| Zone classification | Internal Zone 20 / External Zone 22 |

| Voltage / Frequency | 220–240 V / 50–60 Hz |

| Motor / Power | 1200 W – single-phase by-pass motor |

| Airflow | 194 m³/h |

| Vacuum | 2,504 mm H₂O |

| Tank capacity | 19 L – AISI 316 autoclavable |

| Filtration | Main filter (epitropic polyester), safety filter, dual ULPA U15 |

| Inlet diameter | 50 mm |

| Sound level | 75 dB(A) |

| Dimensions (L×W×H) | 48 × 46 × 88 cm |

| Weight | 30 kg |

| Cord length | 10.6 m |

| Standard accessories | CWR EX kit, ULPA filters, safety filter, conductive recovery bags |