Tiger-Vac C-10 EX (IT-40L) CFE HEPA

Inert “Wet Mix” system for metallic dust – three certified variants

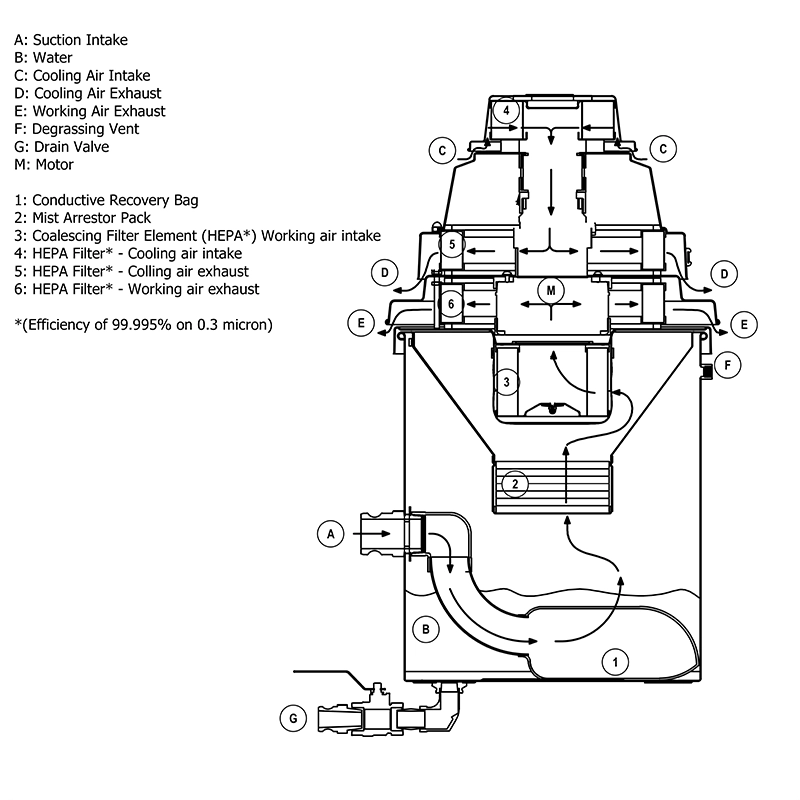

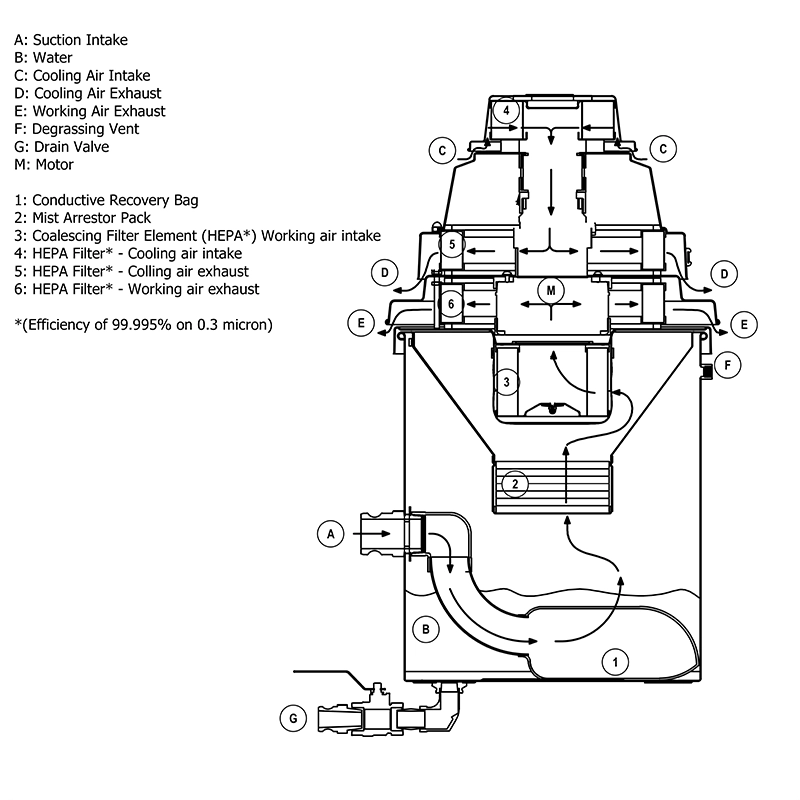

The Tiger-Vac C-10 EX (IT-40L) CFE HEPA is a compact, certified immersion separator designed for the safe collection and neutralisation of combustible and conductive metallic dust through a controlled water bath. The series is available in three variants that differ only in certification level, temperature class and motor output. All versions operate using the same principle: dust is drawn into 12.3 L of water, captured inside a conductive wet recovery bag, then processed through a CFE coalescing filter element and a H14 HEPA final filtration stage.

Difference between the three models

Standard model (113178B): IECEx and ATEX certified with a T200°C temperature rating, 1.2 kW motor and 194 m³/h airflow. Suitable for general inert recovery of aluminium, copper, titanium and metallic powders used in additive manufacturing.

EN17348 version (113178B-17348): Technically identical to the standard model but tested and documented according to EN 17348 WT for the safe collection of self-heating and reactive metallic dusts. Often required for EU-based AM facilities handling sensitive metal powders.

BLSD model (113178B-BLSD): Low-temperature version certified to T85°C, equipped with a 1.1 kW motor and a higher 216 m³/h airflow. Ideal for metal powders with low ignition energy or temperature-sensitive processes. Compatible with the brushless motor option (always supplied with 4 × H14 HEPA filters).

Inert vs. ATEX – do you know the difference?

Read our guide explaining why inert technology is essential for metallic dust, self-heating materials and reactive powders – and when ATEX alone is not enough.

Technical design and inertisation process

Dust is drawn through a 38 mm inlet directly into the water bath where it is neutralised within the conductive wet recovery bag. Larger particles remain in the bag, while aerosols are captured by an upstream HEPA-grade coalescing filter (CFE). Both cooling air and working air are then filtered through H14 HEPA 99.995% (MPPS) to prevent fine metallic particles from leaving the machine. An integrated mist arrestor pack prevents moisture carryover to the motor. The system is built in AISI 304 stainless steel and includes a clear liquid level indicator and a degassing vent for safe pressure release.

Safety and certification

- IECEx: Ex h tc IIIC T85°C/T200°C Dc IP6X – internal Ex h IIIC T85°C/T200°C Da.

- ATEX: II 1/3D (internal Zone 20, external Zone 22).

- EN 17348 version available for self-heating dusts (variant 113178B-17348).

- Low-temperature T85°C model for heat-sensitive materials (variant 113178B-BLSD).

- All models are ESD safe (< 10 Ω) and supplied with a complete static dissipative tool kit.

Technical advisory

This series is designed specifically for the collection of metallic, conductive and reactive dusts, which must not be collected with conventional dry ATEX vacuums. Immersion in water prevents ignition, sparks and thermal runaway. The user must always verify water compatibility with the specific metal powder. Only conductive hoses and accessories may be used to maintain correct bonding and grounding. The degassing vent must remain unobstructed at all times.

Need advice on inert wet-mix systems?

We can help you choose the correct model, liquid setup, safety documentation and Zone 22 installation.

FAQ

Which model should I choose?

Standard for general metallic dust, EN17348 for self-heating dusts, BLSD for temperature-sensitive processes.

Which liquid must be used?

Water. This model series must not be used with oil, as the manufacturer explicitly specifies water as the inertisation medium.

Can it collect organic combustible dust?

No. Inert systems are exclusively for metallic dust.

How does the conductive recovery system work?

Dust settles inside the conductive wet recovery bag while submerged in water. Metallic particles are neutralised and safely contained.

Related links

Technical specifications

| Specification | Standard 113178B | EN17348 113178B-17348 | BLSD 113178B-BLSD |

|---|---|---|---|

| ATEX / IECEx marking | II 1/3D – T200°C | II 1/3D – T200°C + EN 17348 WT | II 1/3D – T85°C |

| Voltage | 220–240 V | 220–240 V | 220–240 V |

| Power | 1.2 kW | 1.2 kW | 1.1 kW |

| Current | 5 A | 5 A | 8 A |

| Airflow | 194 m³/h | 194 m³/h | 216 m³/h |

| Vacuum | 2,504 mm H₂O | 2,504 mm H₂O | 2,250 mm H₂O |

| Noise level | 72 dB(A) | 72 dB(A) | 72 dB(A) |

| Inlet diameter | 38 mm | 38 mm | 38 mm |

| CFE filter | HEPA-grade coalescing | HEPA-grade coalescing | HEPA-grade coalescing |

| HEPA filtration | H14 – 99.995% | H14 – 99.995% | H14 – 99.995% (4× with brushless) |

| Minimum water load | 12.3 L | 12.3 L | 12.3 L |

| Recovery capacity | 3 L (wet bag) | 3 L | 3 L |

| Material | AISI 304 stainless steel | AISI 304 | AISI 304 |

| Dimensions (L×W×H) | 48 × 46 × 89 cm | 48 × 46 × 89 cm | 48 × 46 × 89 cm |

| Weight | 28.1 kg | 28.1 kg | 28.1 kg |

| Accessories | Complete static dissipative tool kit incl. hose, wands, floor tool, conical nozzle, Tiger Claw, round brush and multimeter | ||