Tiger-Vac C-35L EX DT (MRP)

ATEX 1/3D industrial vacuum cleaner with removable recovery tank and MRP filter cleaning system for combustible dust in Zone 22 and internal Zone 20

The Tiger-Vac C-35L EX DT (MRP) is an ATEX- and IECEx-certified industrial vacuum cleaner designed for the safe recovery of combustible and conductive dust in areas classified as Zone 22, while providing a very high level of protection inside the filtration and airflow system (internal Zone 20). The unit features a removable stainless-steel recovery tank on wheels, allowing fast, ergonomic and dust-minimised emptying. It is third-party certified by LCIE (0081) as II 1/3D with internal Ex h IIIC T135°C Da and external Ex h tc IIIC T135°C Dc IP6X, and is tested according to EN 17348 DT for combustible dust collection.

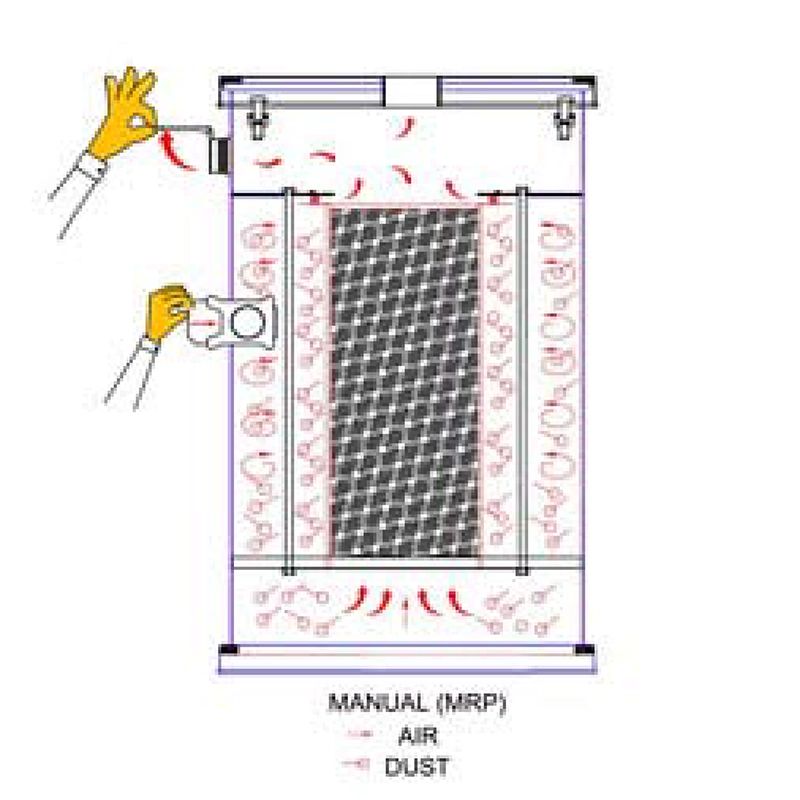

MRP filtration system – manual filter cleaning during operation

The advanced MRP (Manual Reverse Purge) filtration system allows the operator to clean the main filter manually during operation without opening the tank. A rotating handle on the filter housing creates a reverse pulse of air that dislodges dust from the filter media and significantly extends filter life. The system includes a large static-dissipative primary filter combined with multiple downstream HEPA H14 filters, each individually tested to 99.99% efficiency at 0.3 µm.

Ergonomic design with removable dust collection tank

The C-35L EX DT (MRP) includes a 35-litre stainless-steel recovery tank mounted on a separate wheeled carriage. By tilting the frame, the tank is released and can be rolled away for safe and easy emptying without lifting. This makes the model ideal for production sites with frequent emptying cycles or processes generating moderate to large volumes of combustible dust.

ATEX, IECEx and EN 17348 certification

The vacuum is fully certified in accordance with IECEx LCIE 15.0048, LCIE 15 ATEX 3061 and LCIE 19 ATEX 1001 X. Both the internal dust-handling area (Zone 20 / Da) and the external surfaces (Zone 22 / Dc) are assessed according to EN IEC 60079-0, EN 60079-31 and EN ISO 80079-36/37. The unit is additionally tested for combustible dust recovery according to EN 17348, ensuring safety during normal operation and maintenance activities.

Industries and applications

The C-35L EX DT (MRP) is ideal for general cleaning in production areas where combustible dust is present: food ingredients, sugar, starch, flour, milk powder, pharmaceutical and biotech production, chemical powders, plastic and rubber granulates, composite and metal dust, as well as 3D printing and additive manufacturing environments. The removable tank design is especially useful in production lines and packaging areas requiring frequent dust disposal.

Standard accessories – static-dissipative tool kit

The vacuum is supplied with a complete static-dissipative tool kit: conductive suction hose (38 mm × 3 m), chrome curved handle with airflow control, two 32 mm extension wands, ESD-safe floor tool with conductive nylon bristles, round brush, crevice tool and upholstery tool. An antistatic main filter, downstream HEPA H14 filters and a cable holder on the powerhead are also included.

Optional accessories and configuration

Optional accessories include static conductive hoses up to 15 m, hose cuffs, unions, 38 mm double-bend wand, larger ESD floor tools and 38–32 mm reducers. A high-temperature primary filter (SD) is available for processes involving warm air or hot dust. This makes it possible to integrate the vacuum into process equipment, filling lines or semi-centralised extraction systems while maintaining full ATEX and ESD compatibility.

Technical note on internal Zone 20 and bonding

As an II 1/3D certified vacuum cleaner, the C-35L EX DT (MRP) is approved for the safe recovery of combustible dust inside the internal Zone 20 (Da), while the external structure is suitable for Zone 22 (Dc). To maintain this safety level, hoses, tools, couplings and the operator must form part of a correctly bonded and grounded system. Always use static conductive or static-dissipative accessories and follow ATEX, EN 17348 and site-specific safety procedures.

Need advice on ATEX 1/3D vacuum systems?

We assist with equipment selection, bonding and grounding design, and compliance documentation according to EN 17348 and ATEX 2014/34/EU.

FAQ

What is the advantage of the MRP filtration system?

It allows manual filter cleaning during operation without opening the tank, reducing downtime and extending filter life.

How does the C-35L EX DT (MRP) differ from the BLSD version?

The BLSD model uses a brushless motor with increased lifespan, lower spark potential and improved reliability. Both models share the same ATEX 1/3D certification.

Is the removable recovery tank suitable for large dust volumes?

Yes, the wheeled tank allows quick and ergonomic emptying, making it ideal for frequent disposal cycles.

How many HEPA filters does the system include?

The model features multiple downstream HEPA H14 filters (99.99% @ 0.3 µm) along with a large antistatic primary filter.

Related links

Technical specifications – Tiger-Vac C-35L EX DT (MRP)

| Specification | Data |

|---|---|

| ATEX marking (external) | II 1/3D – Ex h tc IIIC T135°C Dc IP6X |

| ATEX marking (internal) | Ex h IIIC T135°C Da (internal Zone 20) |

| Certification | IECEx LCIE 15.0048, LCIE 15 ATEX 3061, LCIE 19 ATEX 1001 X |

| Zone classification | Internal Zone 20 (Da) / External Zone 22 (Dc) |

| Voltage / Frequency | 220–240 V – 50/60 Hz (1~) |

| Motor type | Universal motor (MR) – 1.2 kW |

| Airflow | 194 m³/h |

| Vacuum | 2,504 mm H₂O |

| Current draw | 5 A |

| Sound level | 72 dB(A) |

| Suction inlet | 60 mm |

| Recovery tank | 35 L – removable stainless-steel tank on wheels |

| HEPA filtration | Downstream HEPA H14 – 99.99% @ 0.3 µm |

| Main filter | Static dissipative primary filter with MRP cleaning system |

| Filter cleaning | MRP – Manual Reverse Purge |

| Tank material | Stainless steel |

| Dimensions (L × W × H) | 62 × 52 × 132 cm |

| Weight | 46 kg |

| Power cord length | 10.6 m |

| Standard accessories | Conductive hose 38 mm, curved handle, 2 × extension wands, ESD floor tool, round brush, crevice tool, upholstery tool, primary filter, HEPA filters |

| Optional accessories | Static conductive hoses up to 15 m, unions, double-bend wand, 38–32 mm reducer, large ESD floor tool, SD high-temperature filter |