Tiger-Vac CD-10/7 EX (APS-EXTENDED)

ATEX-certified high-vacuum system for combustible and conductive dust in Zone 1/21

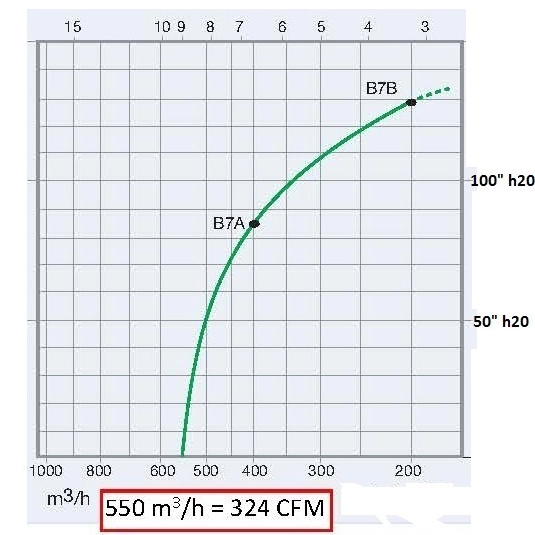

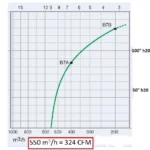

The Tiger-Vac CD-10/7 EX (APS-EXTENDED) 2GD Z1-2-21-22 is a powerful stainless-steel ATEX vacuum cleaner designed for the safe recovery of combustible and conductive dusts in industrial environments where both gas and dust hazards may be present. The 5.5 kW 3-phase explosion-proof motor delivers up to 500 m³/h airflow and 2,540 mm H₂O vacuum, making the system suitable for central vacuum installations, point extraction and heavy-duty cleaning tasks in ATEX Zones 1/2/21/22.

- ATEX & IECEx certified dry recovery vacuum for safe collection of combustible and conductive dust.

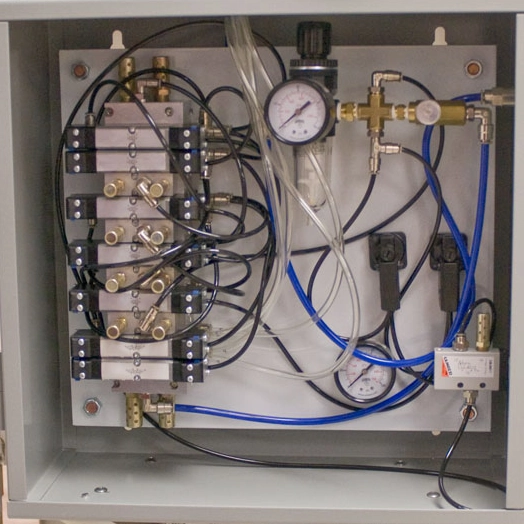

- Automatic Purge System (APS) with 3 conductive aluminized spun-bond filter cartridges and fully integrated diaphragm valves.

- All stainless steel Type 304 construction (except cart) with detachable 56.8 L recovery tank.

- ESD safe system with total resistance < 10 Ω when used with recommended conductive hoses and tools.

- Designed for continuous duty in demanding environments including pharma, chemicals, metal processing and additive manufacturing.

Technical construction

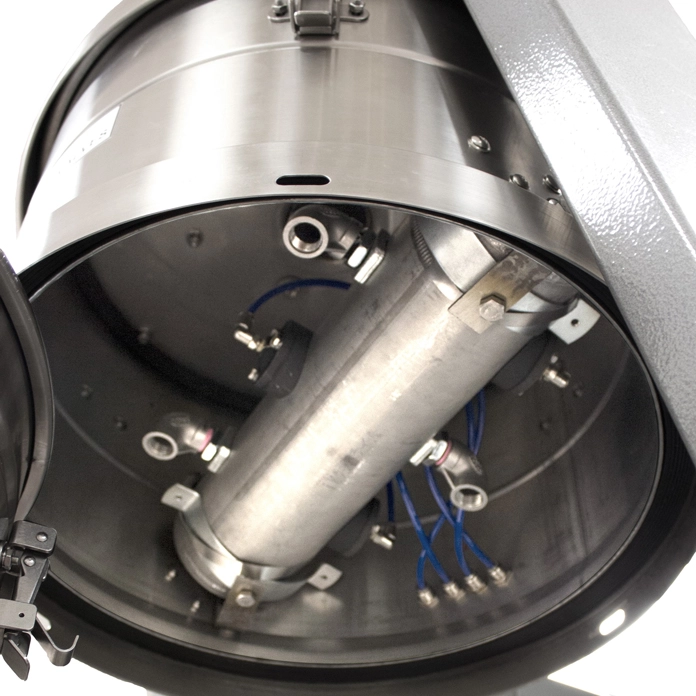

The CD-10/7 EX (APS-EXTENDED) is configured as a dry recovery system with a separate motor compartment, filter chamber and detachable stainless-steel recovery tank mounted on a heavy-duty cart. The top section houses a third-party certified explosion-proof TEFC motor (400 V, 50 Hz, 5.5 kW) enclosed to IP65 for Dust Group IIIC. Beneath the motor sits the filter chamber with three conductive aluminized spun-bond cartridges. These are automatically cleaned by the APS (Automatic Purge System) using three fully integrated diaphragm valves controlled by pneumatic timers. An upstream see-thru polyester safety filter offers additional motor protection.

The collected dust is discharged into a 56.8 L detachable stainless-steel tank (DT) that slides out for clean removal without opening the filter chamber. The suction inlet is Ø63.5 mm (2.5") Camlock, and the unit can be equipped with static dissipative or explosion-proof hoses and tools in Ø38 mm, Ø50 mm or 70 mm – including mandatory tools for conductive metal dust, pyrotechnic dust or other high-risk applications.

Safety & certification

- ATEX marking: 0081 II 1/2GD with external protection Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 and internal protection Ex h IIC T6 Ga / Ex h IIIC T50°C Da. Certificate: LCIE 03 ATEX 6295 X.

- IECEx certified (CD EX Series): IECEx LCI 10.0040X including the new Ex h protection for internal surfaces.

- Designed for safe recovery of combustible dust using a Dry Type dust collector, ambient range -5 °C to +37 °C.

- Complies with EN 17348 for combustible dust collection and relevant parts of IEC/EN 60079 and IEC 60335-2-69 for vacuum cleaners in explosive atmospheres.

- ESD-safe design: total resistance < 10 Ω when using recommended conductive accessories and proper grounding.

Technical note

The CD-10/7 EX (APS-EXTENDED) belongs to the upper range of Tiger-Vac’s CD Series, engineered for heavy-duty point extraction from process equipment as well as manual cleaning in hazardous areas. The ATEX marking II 1/2GD indicates that the inside of the collector and filter chamber is suitable for Zone 20 (Category 1D) and potentially Zone 0 (Category 1G), while the outer surfaces are certified for Zone 21/22 and Zone 1/2 depending on the configuration. In practice, the unit is widely used in Zone 1/21 environments involving combustible or conductive dusts.

To maintain full compliance, the vacuum must be integrated into a fully bonded and grounded system with conductive hoses, tools, pipework and verified earthing points. Resistance and bonding should be checked as part of the site’s ATEX/ESD program according to TRGS 727, NFPA 77 and EN 80079-36.

Typical applications

Pharmaceutical production, chemical processing, additive manufacturing (3D printing powders), metal powders, battery production, electronic component manufacturing, food powders and general combustible dust handling.

Technical specifications

| Specification | Data |

|---|---|

| ATEX / IECEx marking | II 1/2GD – Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 (external) – Ex h IIC T6 Ga / Ex h IIIC T50°C Da (internal) |

| Typical zones | Zone 20 internal / Zone 21 external / Zone 1 gas (installation dependent) |

| Voltage / Frequency | 400 V – 50 Hz (3~) |

| Power / Current | 5.5 kW / approx. 11.5 A |

| Airflow | 500 m³/h |

| Vacuum | 2,540 mm H₂O – VRV approx. 1,780 mm H₂O |

| Noise level | 68 dB(A) with muffler (approx. 90 dB(A) without) |

| Suction inlet | Ø63.5 mm Camlock – accessories in Ø38 / Ø50 / 70 mm |

| Recovery tank | 56.8 L stainless steel detachable tank (DT) |

| Primary filter | 3 x conductive aluminized spun-bond cartridges (APS reverse purge) |

| Safety filter | See-thru polyester safety filter element (upstream) |

| HEPA filter | 22" HEPA housing included, H14 HEPA filter optional |

| Filter cleaning | Automatic Purge System (APS) |

| Material | AISI 304 stainless steel (tank, filter chamber, housing) |

| Operating mode | Continuous duty – dry recovery only |

| Ambient range | -5 °C to +37 °C (dry collector) |

| Applications | Pharma, chemicals, metals, additive manufacturing, food powders, batteries, electronics |

FAQ

Can the CD-10/7 EX (APS-EXTENDED) be used as a central vacuum unit?

Yes. It is commonly used as a central vacuum power unit connected to pipelines with multiple suction points. Correct system design (pipe diameters, airflow, VRV, accessories) must be calculated for each installation.

What does 2GD Z1-2-21-22 mean?

It indicates certification for both gas (G) and dust (D) — Category 2 for use in Zone 1/21 and Category 3 for Zone 2/22 — while the interior is Category 1 (Zone 0/20). Always confirm zones in your site’s ATEX documentation.

Can the vacuum collect liquids?

No — this version is certified for dry recovery only. Liquids may be collected only in separate certified liquid collectors/interceptors supplied for that purpose.

Which filters are available?

Standard configuration includes 3 conductive APS cartridges and an upstream polyester safety filter. Optional downstream H14 HEPA filter (99.99% @ 0.3 μm) is available for cleanroom, pharma and food applications.

Which accessories must be used for conductive metal dust?

Only the explosion-proof, static-dissipative accessory kits designed for conductive dust recovery may be used. These maintain < 10 Ω resistance and are required for compliance.

Related articles

Key technical features

Third-party ATEX & IECEx certified high-vacuum unit for dry recovery of combustible and conductive dust in Zone 1/2/21/22. Equipped with Automatic Purge System (APS) and a 56.8 L detachable stainless-steel tank for continuous duty use.

| Specification | Data |

|---|---|

| Zone / ATEX | II 1/2GD – typically Zone 1/21 (gas/dust) |

| Motor | 5.5 kW 3-phase TEFC, 400 V |

| Airflow / Vacuum | 500 m³/h / 2,540 mm H₂O |

| Filtration | 3 conductive cartridges (APS) + polyester safety filter; H14 HEPA optional |

| Recovery tank | 56.8 L stainless-steel detachable tank |

| Material | AISI 304 stainless steel |

| Applications | Combustible & conductive dust in pharma, chemicals, metals, AM/3D printing |