Tiger-Vac CD-2600 EX CR (ARP) Z1/21 1/2D

ATEX 1/2D industrial vacuum cleaner for Gas Zone 1 and Dust Zone 21 with Automatic Reverse Purge (ARP)

The Tiger-Vac CD-2600 EX CR (ARP) Z1/21 1/2D is the highest-grade ARP variant in the CD-2600 EX series, designed for environments where both flammable gases (Zone 1) and combustible dusts (Zone 21) may be present. The model is built on the fully third-party certified CD EX platform (II 1/2GD), providing internal protection Ex h IIC/IIIC for Zone 0/20 and external protection Ex db/tb for Zone 1/21. This makes the unit suitable for demanding process applications where dual gas and dust classification is required.

Technical design and ARP filter system

The CD-2600 EX CR (ARP) Z1/21 1/2D is equipped with a vertically mounted, explosion-proof 3-phase TEFC motor available in 2.2 kW or 4.0 kW configurations. Both versions offer continuous-duty performance with airflow up to 299 m³/h and vacuum levels up to 3,380 mm H₂O. The ARP (Automatic Reverse Purge) system automatically cleans the static-dissipative filter cartridge during operation, ensuring stable suction even during heavy dust loads. The stainless-steel 36 L recovery tank (AISI 304/316) allows safe, hygienic disposal of combustible dusts.

Safety, ATEX 1/2D and ESD control

This model is engineered for installations where both explosive gas atmospheres and explosive dust atmospheres may occur around the equipment. The EX-tested motor enclosure, filter housing and electrical components provide certified ignition protection, while hoses and nozzles follow ATEX/ESD standards. The complete system is fully ESD-safe with total resistance below 10 Ω. The combination of Gas Zone 1 and Dust Zone 21 capability makes this model ideal for complex ATEX installations where 2D or 3D models are insufficient.

Typical applications

The CD-2600 EX CR (ARP) Z1/21 1/2D is used in environments with simultaneous gas and dust risks, including pharmaceutical and biotech production, API handling, chemical plants, solvent-based processes, powder handling, spray-drying, blending, silo discharge areas and filling lines. Its stainless-steel construction and optional HEPA/ULPA final filtration make it suitable for ATEX, GMP and hygienic production areas.

Need assistance with ATEX 1/2D installations?

We support facilities with correct system sizing, documentation and compliant ESD/ATEX accessories for gas and dust applications.

Technical note

The Z1/21 1/2D model is a hybrid ATEX solution for installations that require both gas and dust classification. It is built on the same CD EX platform tested by LCIE under ATEX and IECEx standards (Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db). While all EX components are certified, hoses and nozzles must be used as part of a properly grounded system and are not individually third-party tested. Correct bonding and grounding are essential for safe operation.

FAQ

What does Z1/21 1/2D mean?

It means the vacuum may be installed in Gas Zone 1 and Dust Zone 21 (Category 1/2D), with internal classification suitable for Zone 20 dust.

Who typically uses this model?

Pharmaceutical plants, chemical facilities, API handling, solvent-based production, powder processing, spray-drying and mixed gas/dust environments.

Why choose ARP?

ARP cleans the filter automatically during operation, ensuring stable suction performance and reduced maintenance under heavy dust loads.

Related links

Technical specifications – Tiger-Vac CD-2600 EX CR (ARP) Z1/21 1/2D

| Specification | 2.2 kW model | 4.0 kW model |

|---|---|---|

| Certification series | CD EX Series — ATEX/IECEx certified (II 1/2D) | |

| Zone classification (model) | Gas Zone 1 + Dust Zone 21 (Category 1/2D) | |

| Voltage / Frequency | 400 V – 50 Hz | 400 V – 50 Hz |

| Phase | Three-phase (TEFC) | Three-phase (TEFC) |

| Power | 2.2 kW | 4.0 kW |

| Current draw | 4.3 A | 8.2 A |

| Airflow | 200 m³/h | 299 m³/h |

| Vacuum | 2,540 mm H₂O | 3,380 mm H₂O |

| VRV setting | 1,780 mm H₂O | 2,030 mm H₂O |

| Sound level | 68 dB(A) | 68 dB(A) |

| Suction inlet | 50 mm | 50 mm |

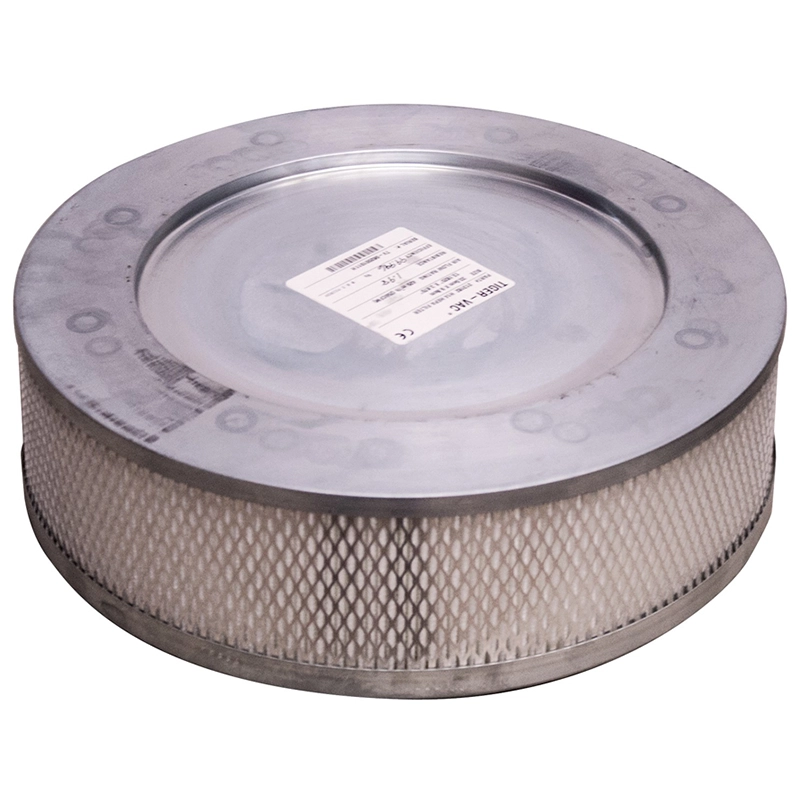

| Filter cleaning | Automatic Reverse Purge (ARP) | |

| Filter cartridge | Static-dissipative filter cartridge (resistance <10 Ω) | |

| Final filtration (optional) | HEPA H14 or ULPA U15 (EN 1822) | |

| Recovery tank | 36 L stainless steel | |

| Materials | AISI 304/316 stainless steel | |

| Duty cycle | Continuous duty | |

| Ambient temperature | -5 °C to +37 °C | |

| Dimensions (L × W × H) | 66 × 51 × 191 cm | |

| Weight | 112 kg | |

| Cord length | 10 m | |