Tiger-Vac CD-2600 EX CR (ARP) Z22 3D

ATEX Zone 22 (3D) industrial vacuum cleaner with Automatic Reverse Purge (ARP)

The Tiger-Vac CD-2600 EX CR (ARP) Z22 3D is a stainless-steel ATEX-certified industrial vacuum system engineered for the safe recovery of combustible and conductive dusts in ATEX Dust Zone 22 areas. The CD EX platform is fully third-party certified (LCIE 0081) according to ATEX and IECEx as II 1/2GD, providing internal protection Ex h IIC/IIIC (Zone 0/20) and external protection Ex db/tb (Zone 1/21). This ensures a documented safe solution for handling explosive dusts in both production and cleaning applications.

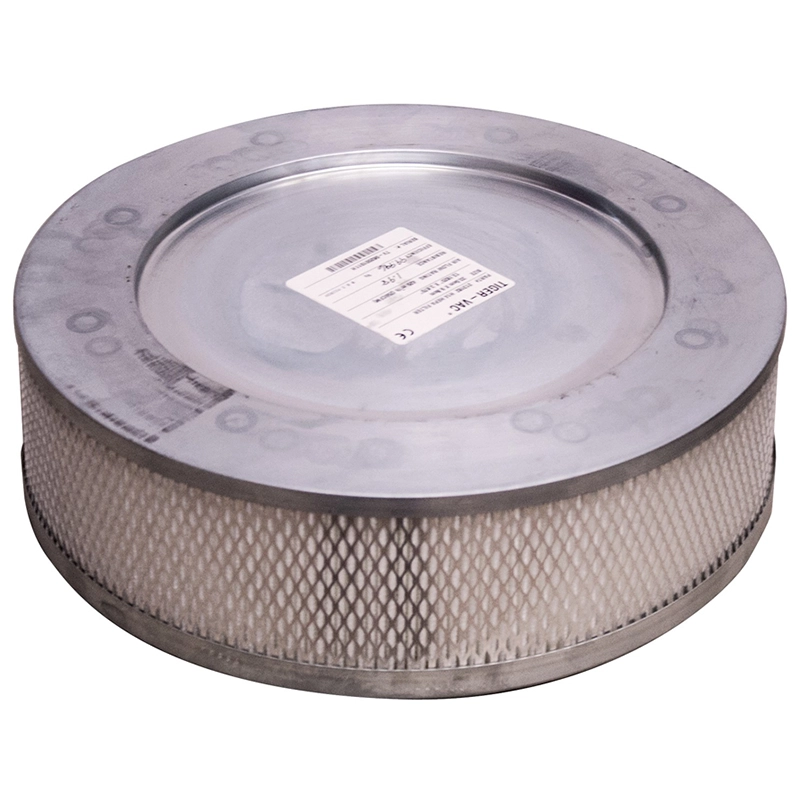

Technical design and ARP filter system

The CD-2600 EX CR (ARP) Z22 3D is a vertically mounted continuous-duty system equipped with an explosion-proof 3-phase motor (TEFC) in either 2.2 kW or 4.0 kW configurations. It delivers up to 299 m³/h airflow and vacuum levels up to 3,380 mm H₂O, depending on the model. The Automatic Reverse Purge (ARP) system continuously cleans the static-dissipative filter cartridge using an automated reverse-airflow mechanism, maintaining low pressure drop and stable suction during extended operation. The removable 36-litre stainless-steel recovery tank ensures clean, safe dust handling with minimal operator exposure.

Safety, ATEX and ESD control

The CD-2600 EX CR (ARP) Z22 3D is part of the CD EX series, ATEX- and IECEx-certified by LCIE (0081) as II 1/2GD with external marking Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 and internal marking Ex h IIC T6 Ga / Ex h IIIC T50°C Da. The entire system is ESD-safe with a total resistance below 10 Ω and tested for combustible and conductive dust recovery in accordance with EN 17348. This makes it a reliable solution for ATEX Zone 22 operations where documented, third-party-tested EX safety is required.

Typical applications

This Z22 3D model is ideal for routine cleaning and process-area dust control in environments with combustible dust, including pharmaceutical production, biotechnology, food and ingredient processing, chemical plants, powder-coating operations, plastics and composite manufacturing, as well as 3D printing and additive manufacturing. Its stainless-steel construction and optional HEPA/ULPA final filtration make it suitable for hygienic production areas where ESD control and ATEX compliance are both required.

Need help choosing the right ATEX Zone 22 vacuum?

We support pharma, biotech, food and industrial facilities with correct sizing, documentation and compliant ESD/ATEX accessories.

Technical note

Although marketed as a Z22 (3D) vacuum cleaner, the unit is part of the CD EX series which is fully third-party ATEX/IECEx certified as II 1/2GD. This means the unit provides certified internal protection for the safe recovery of combustible and conductive dusts with verified temperature limits, sealing integrity and grounding. Accessories such as hoses and nozzles follow ATEX/ESD standards but are not individually third-party tested and must be used as part of a correctly grounded system.

FAQ

What does Z22 3D mean?

This model is designed for operation in ATEX Dust Zone 22 (Category 3D), areas where explosive dust atmospheres occur infrequently and only for short durations.

How does ARP differ from MRP?

ARP (Automatic Reverse Purge) cleans the filter cartridge automatically using a reverse airflow system, maintaining stable suction for continuous-duty applications. MRP requires manual activation.

Is the unit suitable for pharma and hygienic environments?

Yes. The CD EX platform is compatible with ISO Class 4 cleanrooms, and the stainless-steel construction with optional HEPA/ULPA filtration makes it suitable for GMP environments.

Which industries benefit the most?

Pharma, biotech, food and ingredients, chemical processing, powder coating, plastics/composites and 3D printing with combustible powders.

Related links

Technical specifications – Tiger-Vac CD-2600 EX CR (ARP) Z22 3D

| Specification | 2.2 kW model | 4.0 kW model |

|---|---|---|

| Certification series | CD EX Series – Third-party ATEX & IECEx certified II 1/2GD | |

| Model zone classification | Z22 – ATEX Dust Zone 22 (Category 3D) | |

| Voltage / Frequency | 400 V – 50 Hz | 400 V – 50 Hz |

| Phase | Three-phase (TEFC) | Three-phase (TEFC) |

| Power | 2.2 kW (2,200 W) | 4.0 kW (4,000 W) |

| Current draw | 5.2 A | 8.2 A |

| Airflow | 299 m³/h | 299 m³/h |

| Vacuum pressure | 2,540 mm H₂O | 3,380 mm H₂O |

| VRV setting | 1,780 mm H₂O | 2,030 mm H₂O |

| Sound level | 68 dB(A) | 68 dB(A) |

| Suction inlet | 50 mm | 50 mm |

| Filter cleaning system | Automatic Reverse Purge (ARP) | |

| Filter cartridge | Static-dissipative filter cartridge (less than 10 ohms) | |

| Final filtration (optional) | HEPA H14 or ULPA U15 (EN 1822 – leak tested) | |

| Recovery tank | 36 L stainless-steel tank | |

| Materials | All stainless steel – AISI 304/316 | |

| Duty cycle | Continuous duty | |

| Ambient temperature | -5 °C to +37 °C | |

| Dimensions (L × W × H) | 66 × 51 × 191 cm | |

| Weight | 112 kg | |

| Cord length | 10 m | |