Tiger-Vac CD-2600 EX CR (MFS) 2D

Pharma and cleanroom compatible ATEX Zone 21 industrial vacuum cleaner with MFS filter shaker system

The Tiger-Vac CD-2600 EX (MFS) CAT. 2D Z21 is a compact, vertical industrial and pharmaceutical vacuum cleaner designed for the safe recovery of combustible and conductive dusts in Zone 21 environments. The unit is ideal for cleanrooms, tablet production, packaging lines and process machinery where space, hygiene and contamination control are critical. Built from stainless steel (AISI 304/316), equipped with an ESD-safe system with resistance below 10 Ω, and a fully ATEX and IECEx certified motor, it is engineered for demanding applications.

- ATEX: II 1/2D – external: Ex h tb IIIC T135°C Db IP65 / internal: Ex h IIIC T50°C Da.

- IECEx certified motor system (LCI 10.0040X).

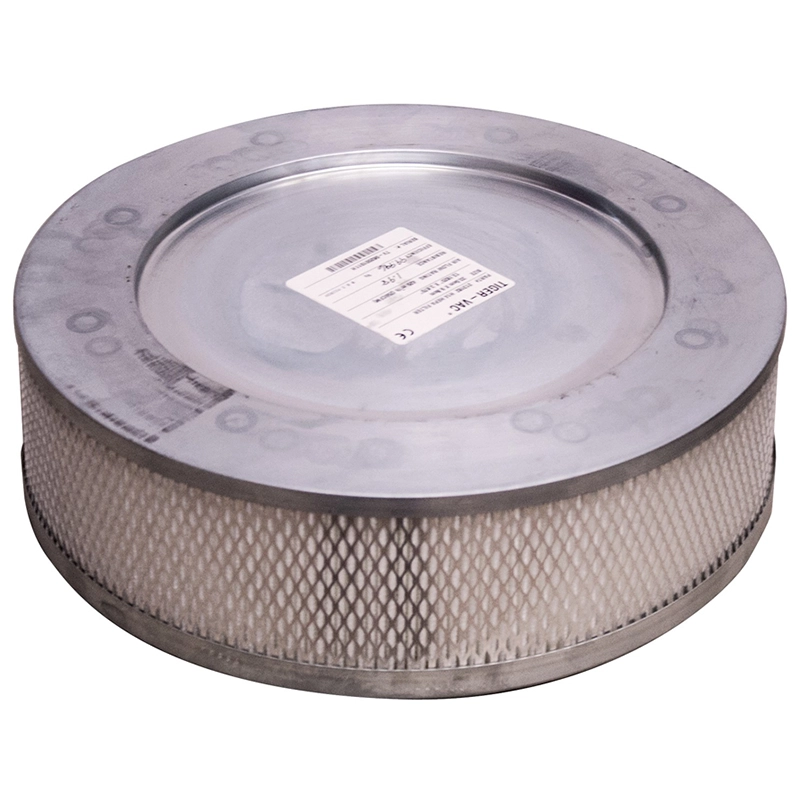

- MFS – Manual Filter Shaker with static dissipative PTFE-laminated main filter.

- Cleanroom compatible down to ISO Class 4 (Class 10).

- Designed for connection to process equipment and general pharmaceutical cleaning.

- Detachable 36 L stainless steel recovery tank (DT) for hygienic waste handling.

Technical design

The CD-2600 EX (MFS) is built in a vertical format to minimise footprint, making it ideal for areas with limited floor space. Its full stainless steel construction (AISI 304/316) and optional HEPA/ULPA filtration make it suitable for pharmaceutical, biotech and medical environments. The unit is designed for dry recovery but can be paired with an external liquid tank if required.

Safety and certification

- ATEX classification: II 1/2D (Zone 20 internal / Zone 21 external).

- Temperature range: –5 °C to +37 °C.

- Tested and approved according to EN 17348 (combustible dust collection).

- All air-contact parts in stainless steel – fully washable for pharma applications.

- Motor housing designed for environments with conductive metal dust (IP65 for Dust Group IIIC).

Technical note

This model is widely used in the pharmaceutical industry because it can be connected directly to tablet presses, capsule fillers and other process machines. Its cleanroom compatibility (ISO Class 4), low noise level (68 dB(A)) and available HEPA/ULPA filtration make it an excellent choice for controlled environments where particle contamination must be tightly managed.

Need advice for pharma or cleanroom installations?

We can help with ATEX classification, documentation and integration with process equipment.

FAQ

Is this model suitable for pharmaceutical and cleanroom use?

Yes — it is fully compatible with ISO Class 4 cleanrooms and widely used in pharma production.

What type of filter cleaning does it use?

MFS – Manual Filter Shaker with PTFE-laminated antistatic main filter.

Can it be supplied with HEPA/ULPA filters?

Yes — optional downstream HEPA H14 and ULPA U15 (99.9995%) units are available.

Can it be connected to process machinery?

Yes — it is designed for integration with tablet presses, capsule machines, fill/finish lines and coating systems.

Can it recover conductive dust?

Yes — system resistance is below 10 Ω, and the unit is certified for Dust Group IIIC.

Related links

Technical specifications

| Specification | CD-2600 EX (MFS) |

|---|---|

| ATEX marking (int/ext) | II 1/2D – Ex h IIIC T50°C Da / Ex h tb IIIC T135°C Db IP65 |

| Zone classification | Zone 20 (internal) / Zone 21 (external) |

| Voltage / Frequency | 400 V – 50 Hz |

| Phase | Three-phase (TEFC) |

| Power | 3.4 kW (3400 W) |

| Current | 8 A |

| Airflow | 306 m³/h |

| Vacuum | 2,540 mm H₂O |

| VRV setting | 1,780 mm H₂O |

| Noise level | 68 dB(A) |

| Suction inlet | Ø50 mm |

| Filter cleaning | MFS – Manual Filter Shaker |

| Main filter | PTFE laminated star filter – SD* antistatic |

| HEPA/ULPA (optional) | HEPA H14 / ULPA U15 (tested to EN 1822) |

| Recovery tank | 36 L detachable tank (DT) |

| Material | Stainless steel AISI 304/316 |

| Dimensions (H×W×L) | 191 × 51 × 66 cm |

| Weight | 112 kg |

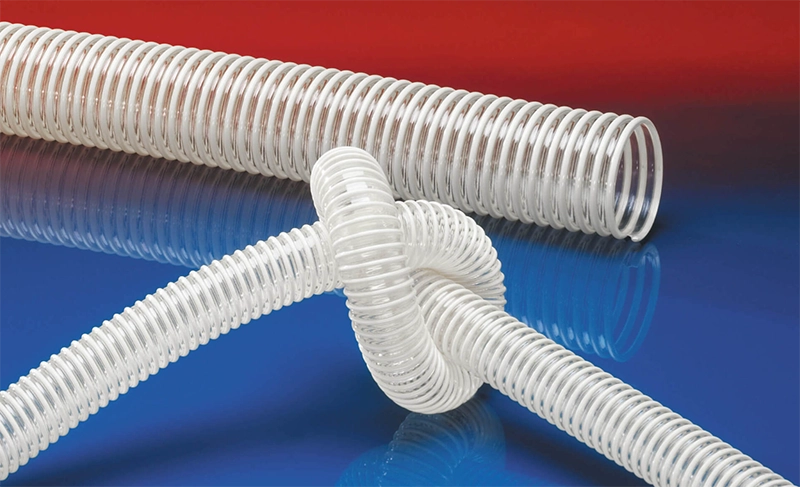

| Accessories | ESD multimeter included; Ø38 and Ø50 mm cleanroom and EX accessories available |