Tiger-Vac CD-EUR-50L EX DT (MFS) 2GD

ATEX 1/2GD industrial vacuum cleaner for Zone 1, 2, 21 and 22

The Tiger-Vac CD/EUR-50L EX DT (MFS) 2GD is a vertically mounted, IECEx- and ATEX-certified industrial vacuum system designed for the safe recovery of combustible and conductive dusts. The unit is certified as II 1/2GD with internal Zone 20/21 protection and external Zone 1/21/22 protection. It includes a U15 ULPA final filter, Manual Filter Shaker (MFS), True Cyclone Separator and a detachable 50 L recovery tank in stainless steel 304.

- ATEX Category 1/2GD certified by Notify Body 0081 (LCIE) for Zones 1, 2, 21 and 22.

- IECEx 3rd-party certified (IECEx LCI 10.0040X) for both dust and gas.

- Motor: 4.0 kW 3-phase TEFC explosion-proof / dust ignition-proof motor.

- Filtration: ULPA U15 (included), static dissipative main filter + cyclone pre-separation.

- MFS system: manual filter shaker, no compressed air required.

- Recovery tank: 50 L detachable SS304 container, compatible with poly liners.

- Designed for conductive and metallic dusts (<10 Ω), pharma, biotech, chemical processes, battery production, additive manufacturing and cleanroom applications.

Certification and safety

The vacuum system is fully certified according to IECEx and ATEX, with third-party validation by LCIE. Internal marking is Ex h IIC T6 Ga / Ex h IIIC T50°C Da, while external marking is Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65. The system complies with EN IEC 60079 standards, EN ISO 80079-36/37 and EN 17348 for combustible dust collection.

- Legally certified explosion-proof / dust ignition-proof design.

- Resistivity < 10 Ω – ESD safe, including dissipative wheels and structural components.

- Ambient temperature range: −5 °C to +37 °C (dry dust collection).

- All flamepaths, enclosures and electrical assemblies approved under LCIE 03 ATEX 6295 X.

Construction and performance

The vertical EUR configuration places the motor housing at the top of the system, providing high performance in limited floor space. The suction intake includes a True Cyclone Separator to reduce filter loading and enhance airflow. The static dissipative SD* main filter is mounted in a removable filter chamber and can be cleaned using the MFS mechanism. A U15 ULPA final filter is included and tested according to EN 1822.

- Airflow: 299 m³/h.

- Vacuum: 3,380 mm H₂O.

- VRV setting: 2,030 mm H₂O.

- Sound level: 74 dB(A).

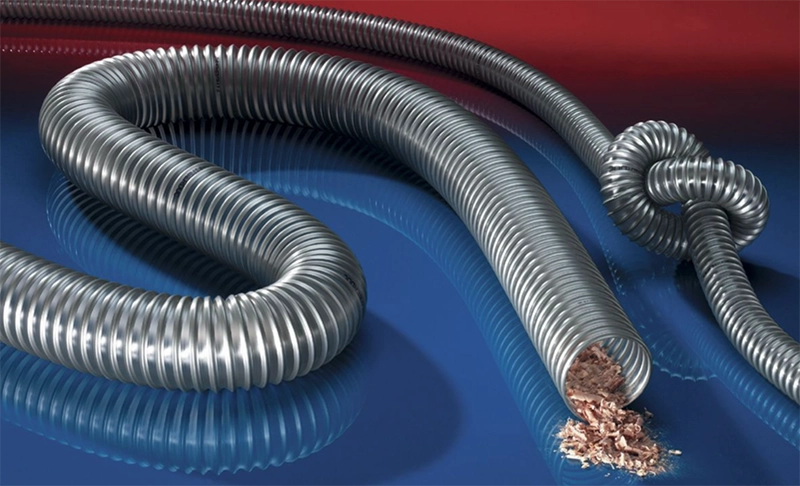

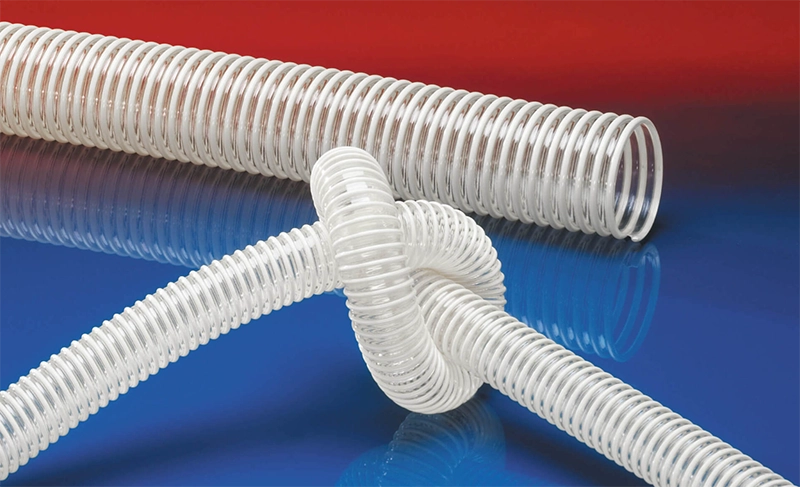

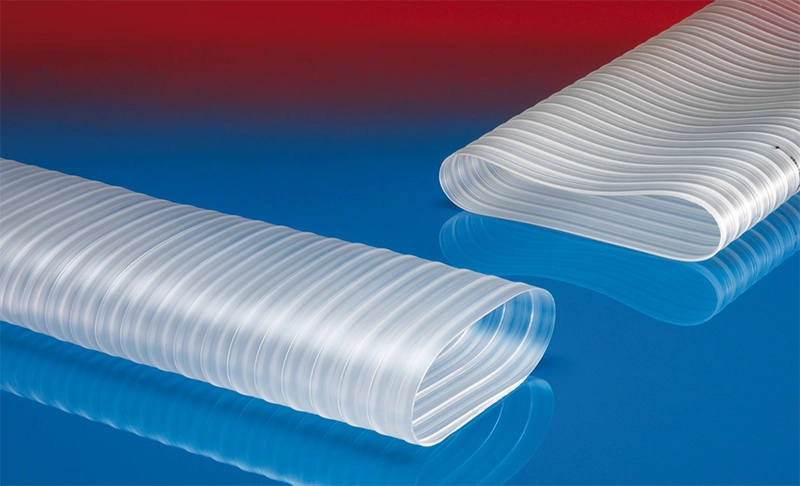

- Suction inlet: Ø63.5 mm – compatible with ESD/EX tools and accessories.

Applications

This model is designed for high-risk environments where both gas and dust explosion hazards may be present and where hygiene and traceable waste handling are essential:

- Pharmaceutical & biotech: stainless steel 304, ULPA U15, cleanroom compatible to ISO Class 4.

- Additive manufacturing & metal powders: safe for conductive dust (<10 Ω).

- Battery production: active materials, conductive particulates, pyrophoric dusts.

- Food industry: combustible powders and fine ingredients.

- Chemical processing: combustible and self-heating dusts.

Technical note

In ATEX 1/2GD environments, proper bonding and grounding is critical. Although the vacuum is built with dissipative components, the user must ensure correct grounding of hoses, tools, pipes and operating practices. For the recovery of conductive/metal dust, certified EX/dissipative accessories (<10 Ω) must be used. All filters, ULPA stages and sealing components must be maintained according to the manufacturer’s guidance to ensure continued ATEX/IECEx compliance.

Need guidance on ATEX 1/2GD equipment?

Get help with zone classification, documentation, accessories and safe handling of combustible or conductive dust.

FAQ

What does 1/2GD mean?

It indicates very high internal protection (1G/1D) and enhanced external protection (2G/2D), suitable for both gas and dust zones.

Can it recover conductive metal dust?

Yes – but only when used with EX-rated and dissipative accessories (<10 Ω).

Is it suitable for pharmaceutical cleanrooms?

Yes. It is cleanroom compatible (ISO Class 4) and delivered with ULPA U15 filtration.

What filtration system does it use?

Manual Filter Shaker (MFS), cyclone pre-separator, dissipative SD* main filter and ULPA U15 final filtration.

Can it be used in Zone 1?

Yes. It is certified as II 1/2GD and validated for both gas and dust applications.

Related links

Technical specifications

| Specification | Data |

|---|---|

| ATEX/IECEx | II 1/2GD – Ex db h IIB T4 Gb / Ex h tb IIIC T135°C Db IP65 (External) · Ex h IIC T6 Ga / Ex h IIIC T50°C Da (Internal) |

| Certificates | IECEx LCI 10.0040X · LCIE 03 ATEX 6295 X |

| Voltage / Frequency | 400 V – 50 Hz |

| Phase | 3-phase |

| Wattage / Power | 4,000 W / 4 kW |

| Amperage | 8.7 A |

| Airflow | 299 m³/h |

| Vacuum | 3,380 mm H₂O |

| VRV setting | 2,030 mm H₂O |

| Sound level | 74 dB(A) |

| Suction inlet | Ø63.5 mm |

| Filter cleaning | MFS – Manual Filter Shaker |

| Main filter | Static dissipative SD* filter (14 sq.ft) |

| Final filter | ULPA U15 – 99.999% @ 0.12 µm |

| Cyclone | True Cyclone Separator at intake |

| Recovery tank | 50 L detachable SS304 tank (DT) |

| Ambient range | −5 °C to +37 °C (dry recovery) |

| Materials | Stainless steel 304 (main body) / dissipative wheels |

| Dimensions (L×W×H) | 103 × 69 × 201 cm |

| Cord length | 10 m |

| Accessories | ULPA U15 filter included · ESD/EX tools optional |