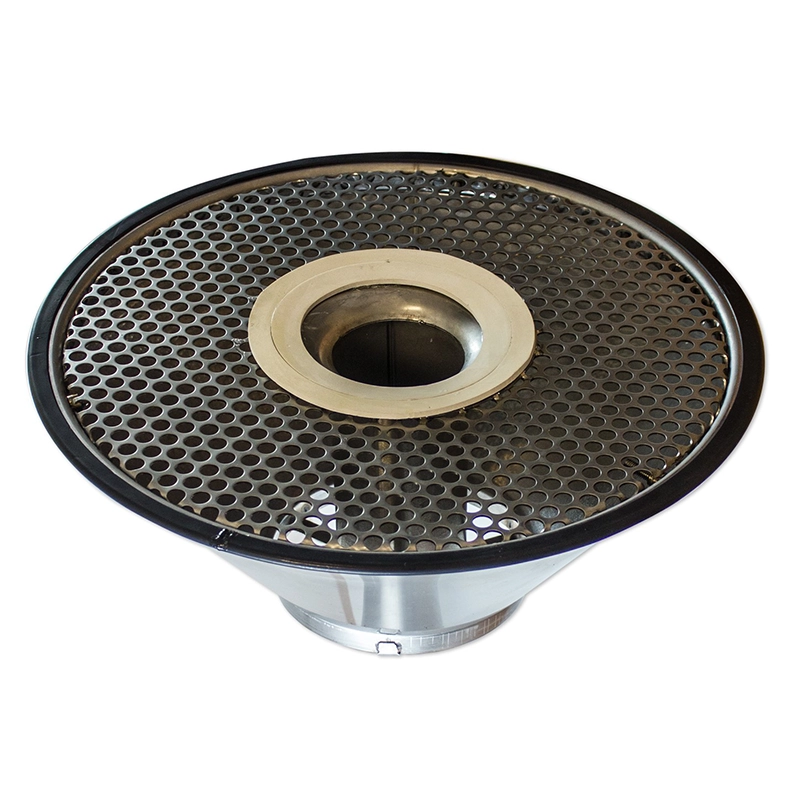

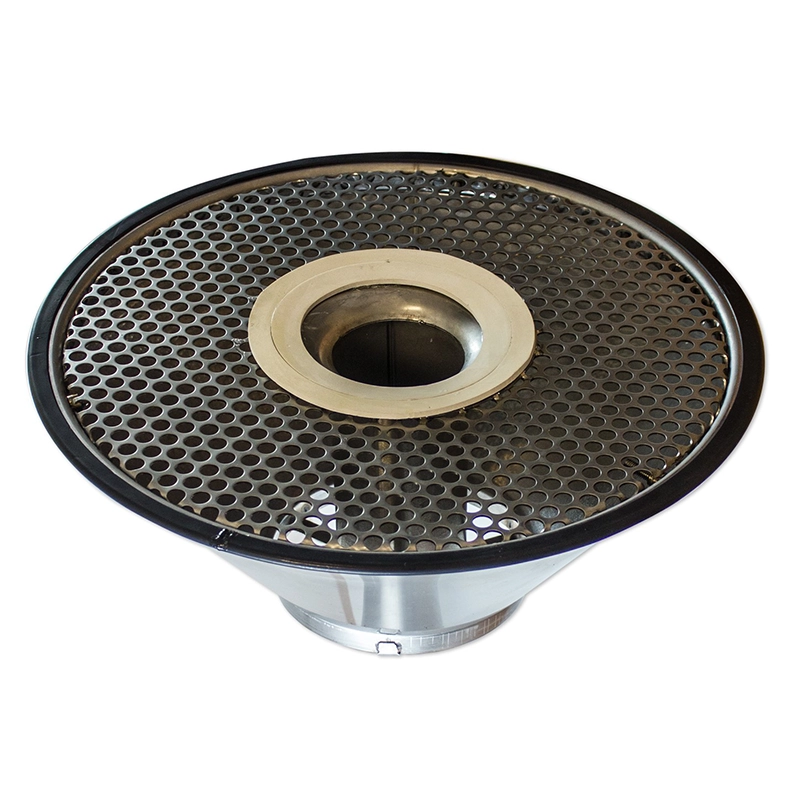

Tiger-Vac CD-IT (85 L) EX (CFE) HEPA INERT 1/2D

ATEX Zone 21 vacuum cleaner with inert liquid bath for reactive and conductive dust

The Tiger-Vac CD-IT (85 L) EX (CFE) HEPA INERT 1/2D is a fully certified ATEX and IECEx vacuum cleaner designed for the collection and neutralization of explosive, reactive, and conductive dusts such as aluminum, magnesium, and gunpowder residues. The system uses an inert oil bath (Wet Oil Mix) that immediately cools and isolates dust from oxygen. Certified according to EN 17348 and NFPA 484, it is part of our solution “When a moment’s mistake turns explosive”, ensuring safe collection of reactive dusts in Zone 21 environments.

- Zone classification: II 1/2GD Ex db h IIB T4 Gb Ex h tb IIIC T135°C Db IP65 / Ex h IIC T6 Ga Ex h IIIC T50°C Da

- Certified for Zone 20 (internal) / Zone 21 (external)

- 85 L INERT tank – neutralizes reactive and conductive dust in oil

- Coalescing filter (CFE) for moisture separation + HEPA H14 final filter (99.995 %)

- Motor: 3-phase 400 V – 2.2 kW TEFC (Ex d) – 74 dB(A)

- Airflow 212 m³/h • Vacuum 2540 mm H₂O

- Container: AISI 304 stainless steel – detachable tank (DT) with 30 L oil bath

- Designed for hydrogen and metal dust (“Hydrogen Safe”) per NFPA 484

Technical construction

The CD-IT INERT 1/2D is an immersion separator equipped with a built-in coalescing (CFE) filter that removes oil and moisture from the airstream before HEPA filtration. The conductive AISI 304 collection tank is filled with neutral, non-reactive oil that cools and isolates particles on contact. A liquid level indicator and detachable tank simplify maintenance and safe disposal of reactive waste.

Safety and certification

- ATEX LCIE 03 ATEX 6295 X / IECEx LCI 10.0040 – Zone 20/21 certified system

- Tested to EN 17348 and NFPA 484 (“Liquid Precipitation Collector” for metal dust)

- Explosion-proof (Ex d) motor and switch enclosure – Group E metal dust rating

- Resistance < 10 Ω – ESD-safe construction and full bonding system

- Supplied with ATEX tool kit and CFE filter assembly as standard

Technical note

Unlike standard ATEX vacuums, the CD-IT collects dust directly into an oil bath to prevent heat and spark generation. It is particularly suited for processes where metal dust and gunpowder residues may occur together. With its CFE filter and H14 HEPA final stage, the system complies with NFPA 484 and EN 17348 for hydrogen and metal dust applications. It forms part of our “When a moment’s mistake turns explosive” solution for inert dust collection in Zone 21 areas.

Need guidance on inert collection and Zone 21 equipment?

Get expert advice on certified ATEX vacuum systems for reactive and conductive dust handling.

FAQ

Why an oil bath instead of dry collection?

Dry collection of magnesium, aluminum, or gunpowder dust can create heat and sparks. The oil bath immediately neutralizes and cools the particles.

What is the CFE filter?

A coalescing filter that separates moisture and oil droplets before HEPA filtration to maximize efficiency and filter life.

Is it Hydrogen Safe?

Yes – tested and approved for metal dust and hydrogen applications per NFPA 484.

How is the tank emptied?

Via detachable tank (DT) and bottom drain valve for safe disposal of oil and reactive dust.

Related links

Technical specifications

| Parameter | Value |

|---|---|

| ATEX marking (Int/Ext) | II 1/2GD Ex db h IIB T4 Gb Ex h tb IIIC T135°C Db IP65 / Ex h IIC T6 Ga Ex h IIIC T50°C Da |

| Zone classification | 20 (internal) / 21 (external) |

| Voltage / Frequency | 400 V – 50 Hz (3~) |

| Power / Current | 2.2 kW / 4.8 A |

| Airflow / Vacuum | 212 m³/h / 2540 mm H₂O |

| Noise level | 74 dB(A) |

| Inlet diameter | Ø 50 mm |

| Container capacity | 85 L – AISI 304 stainless steel – INERT oil bath 30 L |

| Primary filter | Coalescing filter (CFE) + M-class polyester |

| HEPA final filter | H14 – 99.995 % (MPPS, EN 1822) |

| Filter cleaning | Maintenance-free CFE filter system |

| Material | AISI 304 stainless steel / ESD-safe components |

| Dimensions (L×W×H) | 119 × 81 × 157 cm |

| Weight | 111 kg |

| Standards | EN 17348, EN IEC 62784:2018, IEC 60335-2-69, NFPA 484 |

| Accessories | ATEX tool kit and liquid level indicator included |