Tiger-Vac EXP1-10 (IT-40L) EX (CFE) HEPA 2GD

Inert ATEX 2GD vacuum cleaner for water-compatible metal powders from 3D printing and additive manufacturing

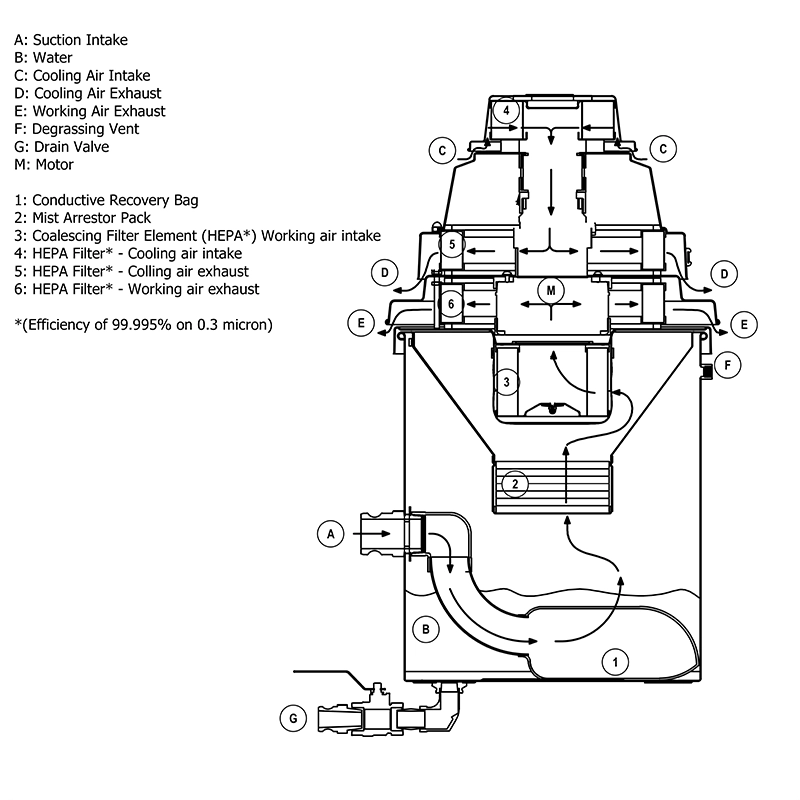

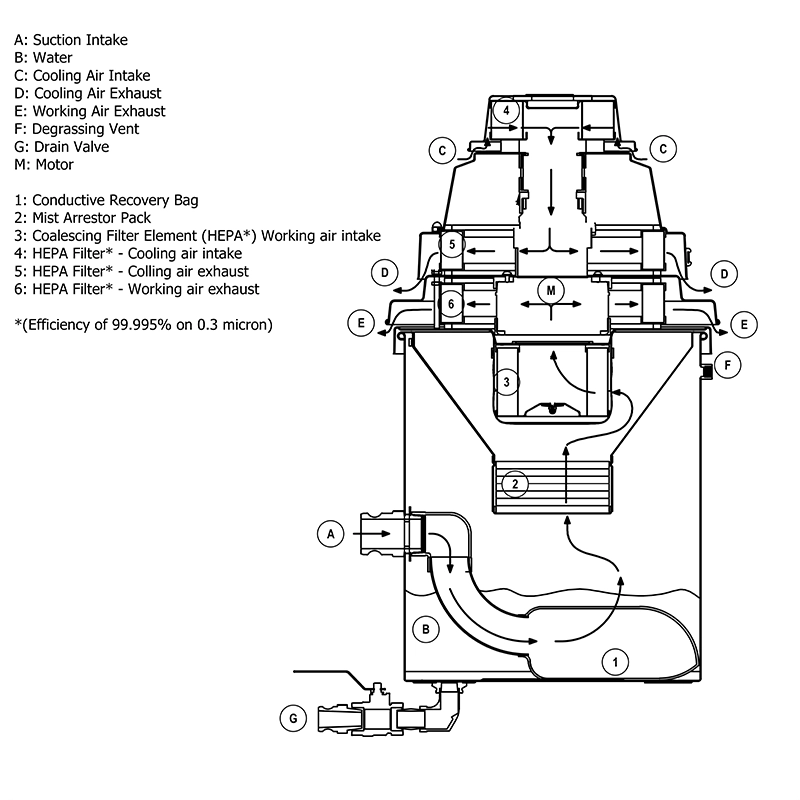

The Tiger-Vac EXP1-10 (IT-40L) EX (CFE) HEPA is a compact inert vacuum cleaner (“Wet Mix – Water Only” immersion separator) designed for the safe recovery and neutralisation of water-compatible metallic and conductive dust. The dust is immersed directly into a water bath, where it is cooled and rendered inert to eliminate ignition sources, self-heating and re-ignition risks. The unit is third-party ATEX certified II 2GD Ex d IIA T3 Gb / Ex t IIIC T200°C Db IP6X and tested according to EN 17348 WT for combustible and self-heating dust.

- Designed exclusively for metals and metal powders that are documented to be water compatible.

- AISI 304 stainless steel recovery tank with conductive wet recovery bag for safe handling of wet sludge.

- CFE coalescing HEPA filter with 99.97% efficiency at 0.3 µm for aerosol and moisture separation.

- Third-party ATEX certification (LCIE 03 ATEX 6297) with a fully conductive and ESD-safe recovery system.

Materials that may be recovered

The EXP1-10 (IT-40L) EX (CFE) HEPA must only be used with water as the immersion medium. It is therefore suitable solely for metallic dusts that do not react with water. Typical water-compatible materials include:

- Aluminium (common grades and AM powders where the supplier confirms water compatibility)

- Copper and copper alloys

- Brass

- Many 3D printing metal powders (e.g., copper-, steel- or nickel-based)

- Non-reactive metallic particles or swarf from additive and laboratory processes

The operator must always confirm water compatibility through the material’s Safety Data Sheet and supplier documentation before recovery.

Materials that must NOT be recovered

This vacuum cleaner must not be used with metals that may react violently, generate heat or release hydrogen gas when in contact with water. These materials require oil-based inert systems and are not compatible with this model:

- Magnesium (especially fine powders – strongly reactive in water)

- Lithium (highly reactive – must never be exposed to water)

- Zirconium

- Tantalum

- Water-reactive titanium alloys or ultra-fine titanium powders

- Alkali metals such as sodium and potassium

- Organic combustible dust (e.g., flour, sugar, wood dust) – this is not a metal

If there is any uncertainty, the material must be evaluated through supplier process data or handled in an oil-based inert system certified for such applications.

Technical design and inertisation

The EXP1-10 (IT-40L) functions as a compact wet-mix inert system in which dust is directed into a water-filled tank (approx. 12.3 L). The conductive wet recovery bag collects up to 3 L of wet sludge. The machine includes a degassing valve for safe venting, a visible liquid level indicator, and a CFE coalescing HEPA filter that captures aerosols before discharge. Delivered with conductive hose, stainless steel wands, floor tool, crevice tool, Tiger-Claw tool, round brush and a multimeter for grounding verification.

Inert or ATEX – do you know the difference?

Highly reactive metal dust may require inert technology instead of conventional ATEX vacuums. Read when wet-mix technology is mandatory and when ATEX alone is sufficient.

Safety, ATEX and operational limits

- ATEX marking: II 2GD Ex d IIA T3 Gb / Ex t IIIC T200°C Db IP6X, ambient temperature 0–40 °C (Ta).

- EN 17348 WT tested for combustible and self-heating dust.

- Only water may be used as the inertising medium – oil is not permitted for this model.

- System resistance below 10 Ω ensures ESD-safe recovery when used with the supplied conductive accessories.

- The customer is responsible for verifying water compatibility of the processed material.

Technical note on inert technology

Water-based inertisation is effective for many metal powders in additive manufacturing, but must never be used with water-reactive metals. The choice between water and oil is determined entirely by the metal’s reactivity and must always be verified using supplier process data. The EXP1-10 (IT-40L) EX (CFE) HEPA is certified strictly as a water-only inert system and must not be modified or filled with other liquids. Proper grounding, liquid level verification and use of conductive accessories are essential for safe operation.

FAQ

Which metals is this inert vacuum cleaner suitable for?

It is suitable for water-compatible metallic dust such as aluminium, copper, brass and many AM powders where the supplier confirms that they do not react with water.

Which materials must not be recovered?

Do not recover magnesium, lithium, zirconium, tantalum, some titanium powders, alkali metals or any material known to react with water. These require oil-based inert systems. Organic combustible dust must not be recovered either.

Why can I only use water as the immersion liquid?

The EXP1-10 (IT-40L) is designed and certified as a “Wet Mix – Water Only” inert system. ATEX and EN 17348 compliance are based entirely on the use of water. Using oil or other liquids falls outside the manufacturer’s approval and changes the safety profile.

How do I confirm if a metal powder is water compatible?

Always check the Safety Data Sheet (SDS) and supplier process documentation for water reaction information. If in doubt, the material must be handled in an oil-based inert system certified for reactive metals.

Can I use this vacuum for organic combustible dust?

No. This model is designed for metallic dust only. Organic dust should be recovered using appropriate ATEX or ACD-certified equipment.

Need advice on inert or ATEX systems?

Contact us for guidance on inertisation, material compatibility and safe recovery of metal powders in additive and laboratory environments.

Technical Specifications

| Specification | Data |

|---|---|

| Model | Tiger-Vac EXP1-10 (IT-40L) EX (CFE) HEPA |

| Type | Inert immersion separator “Wet Mix – Water Only” |

| ATEX marking | II 2GD Ex d IIA T3 Gb / Ex t IIIC T200°C Db IP6X |

| Certifications | ATEX 3rd-party certified, LCIE 03 ATEX 6297, EN 17348 WT |

| Zone classification | Suitable for correctly designed Zone 1/2 (gas) and Zone 21/22 (dust) installations |

| Voltage / Frequency | 230 V – 50 Hz (1~) |

| Power / Current | 1,000 W / 4.5 A |

| Airflow | 224 m³/h |

| Vacuum | 1,550 mm H₂O |

| Noise level | 78–85 dB(A) |

| Suction inlet | 38 mm camlock inlet |

| Filtration principle | Water immersion + coalescing HEPA filter (upstream) |

| Filter efficiency | HEPA-grade CFE, 99.97% at 0.3 µm |

| Recovery tank | AISI 304 stainless steel – approx. 12.3 L water required |

| Wet recovery bag | Conductive bag – approx. 3 L sludge capacity |

| Liquid level / Drain | Integrated sight level and drain valve |

| Degassing | Degassing valve for safe venting |

| Trolley | 4-wheel dolly (4W) with locking casters |

| Materials | AISI 304 stainless steel tank, conductive accessories |

| Dimensions (L × W × H) | 48 × 46 × 86 cm |

| Weight | 31.8 kg |

| Cord length | 15 m |

| Ambient temperature | 0–40 °C (Ta) |

| Standard accessories | Conductive hose 1.5" × 3 m, stainless steel wands, floor tool, crevice tool, Tiger-Claw tool, round brush, multimeter |