Tiger-Vac SS-IT (114L) EX 2GD TWIN VENTURI OIL MIX PNEUMATIC

Tiger-Vac SS-IT (114L) EX 2GD TWIN VENTURI OIL MIX PNEUMATIC is the most powerful and highest-capacity inert vacuum cleaner in the SS-IT range. With a twin venturi system, significantly increased airflow and a larger recovery capacity, it is designed for continuous industrial operation involving large volumes of reactive, self-heating and explosive metal dust.

Inertization and liquid type

The system uses an Immersion Separator Wet Oil Mix and is intended exclusively for use with mineral oil or another approved neutralizing liquid. Dust is conveyed directly into an oil-based immersion bath where it is bound, isolated from oxygen and stabilized as wet sludge. The use of water is not permitted in this model.

Permitted metals

This model is designed for the safe recovery and inertization of highly reactive and explosive metals such as aluminum, magnesium, zirconium and other commercial alloys, including materials with a high risk of self-heating and gas generation.

Prohibited materials

Organic dust, non-metallic materials and materials without documented compatibility with oil must not be collected. The customer must always verify the material safety data sheet before use.

Twin venturi and suction performance

The integrated twin venturi configuration provides substantially increased suction performance and an airflow of up to 331 m³/h. The system is optimized for heavy-duty industrial applications where large quantities of fine and dense metal dust must be collected safely and efficiently.

Technical design

The vacuum cleaner is air-operated and based on the Venturi principle, with no electrical components or moving mechanical parts. The construction is made of AISI 304 stainless steel and mounted on a heavy-duty frame with a detachable recovery tank.

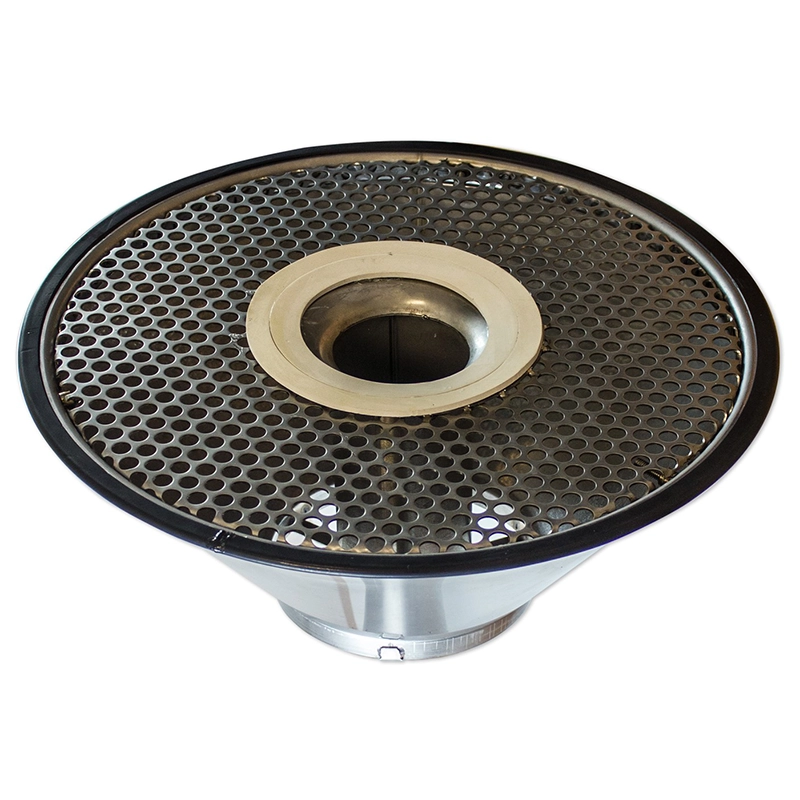

Filtration

The system is equipped with a stainless steel Coalescing Filter Element for efficient separation of oil aerosols, as well as a HEPA H14 filter with a documented efficiency of 99.995% at 0.3 micron. All HEPA units are aerosol leak tested before delivery.

Safety and certification

The SS-IT (114L) TWIN VENTURI is ATEX 2GD certified and IECEx approved with Ex h IIC T6 Gb and Ex h IIIC T85°C Db. The system is ESD-safe with a documented resistance below 10 ohms and is explicitly designated as hydrogen safe. The equipment complies with EN 17348 WT and NFPA 484 for wet inertization of metal dust.

Industries and applications

Suitable for large-scale metal additive manufacturing and 3D printing, powder metallurgy, heavy metalworking, laboratories, the energy sector and other processes with high demands for capacity, stability and safety.

Inert or ATEX – do you know the difference?

When handling reactive and self-heating metal dust, ATEX alone is often not sufficient. Learn when inertization becomes a critical safety requirement.

Accessories and optional equipment

Included are a HEPA H14 filter, coalescing filter element, sieve basket, liquid level indicator, conductive hoses and a complete tool kit. Optional equipment includes a rupture disk, degassing valve, extraction arm with various hoods and an upgrade to a reinforced stainless steel frame.

Professional note

The Twin Venturi model is the preferred choice for high dust volumes, continuous operation and maximum process robustness. It combines the highest level of inert safety with significantly increased capacity and is designed for industrial environments where no compromises are acceptable.

Relevant knowledge and standards

- ATEX ABC – before sparks, there are choices

- ATEX approval is no longer enough – know EN 17348

- Know your ohm – know your ATEX risk

Need advice on large inert systems?

Contact us for assessment of capacity requirements, liquid selection and correct inert system configuration.

All values are provided by the manufacturer at approx. 20 °C. Subject to technical changes.

| Type | Pneumatic inert vacuum cleaner |

| ATEX classification | II 2GD |

| Operating principle | Twin Venturi |

| Venturi diameter | 2 × 5 mm |

| Minimum compressor | 30 HP |

| Air connection | 1" (25.4 mm) |

| Input air volume | 47 L/s |

| Input air pressure | 6.9 bar |

| Air flow | 331 m³/h |

| Vacuum | 3050 mm H₂O |

| Suction inlet | 50 mm |

| Liquid type | Oil only – Wet Oil Mix |

| Liquid volume | 45 liters |

| Tank type | Detachable Tank (DT) |

| Filtration | HEPA H14 + Coalescing Filter Element |

| Construction | AISI 304 stainless steel |

| Dimensions | H 201 × W 76 × L 102 cm |

| Weight | 124 kg |