Tiger-Vac TV-1200 (OL) EU

Industrial dust collector for process-related extraction with 2,000 m³/h airflow

Tiger-Vac TV-1200 (OL) EU is a mobile industrial dust collector designed for demanding process-related extraction of airborne and suspended dust. The unit operates on the principle of low vacuum and high airflow and delivers a documented airflow of 2,000 m³/h.

The dust collector is built for continuous industrial operation and is equipped with a 3-phase TEFC induction motor. The motor is described by the manufacturer as having no arcing components and is fitted with thermal overload protection.

Applications

TV-1200 (OL) EU is typically used for process extraction and point extraction where stable airflow and reliable filtration are required close to the source.

- Extraction during filling, dosing and material handling

- Extraction at conveyors and material transfer points

- Process-related extraction at open process stations

- Indoor extraction where improved exhaust air quality is required

Standard filtration system

The TV-1200 (OL) EU is supplied with a three-stage filtration system consisting of:

- Metal mesh spark trap as pre-filter

- Conductive aluminized spun-bond cartridge filter (12 m² filter area)

- Carbon after-filter for improved exhaust air quality

The manufacturer specifies a filtration efficiency of 97% at 0.3 microns for the standard filter system.

Filter cleaning

Filter cleaning is performed using compressed air via Manual Reverse Purge (MRP).

Connection and configuration

The unit can be configured for process extraction using either two Ø150 mm extraction arms or a single Ø200 mm hose or duct connection.

Optional equipment

- Alternative cartridge filters (Hemipleat Extreme Flame Retardant, 99.99% at 0.5 microns – conductive with carbon)

- Extraction arms in various lengths and diameters

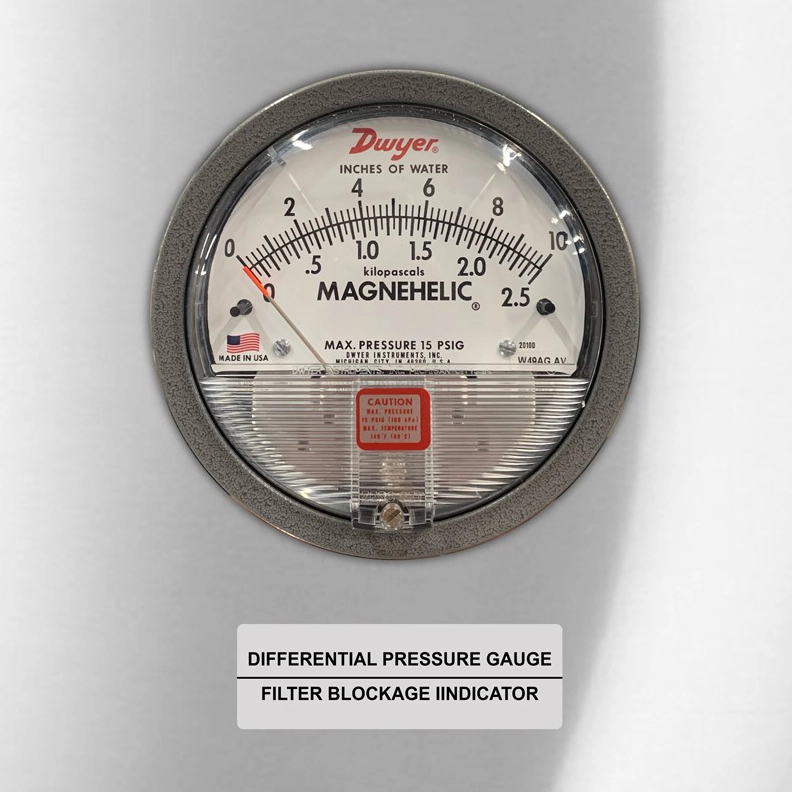

- Differential pressure gauge / filter blockage indicator

- Extraction hoses Ø150 / Ø200 mm with integrated grounding wire

Technical note

TV-1200 (OL) EU is an industrial dust collector designed for dry recovery and process-related extraction with high airflow. The unit is supplied with a pull-out dust drawer with a capacity of 10 litres.

Need assistance?

Contact our specialists to match airflow, extraction arms and filtration to your process.

Related articles

FAQ

What airflow does the unit provide?

2,000 m³/h (manufacturer data).

How are the filters cleaned?

By compressed air using Manual Reverse Purge (MRP).

What inlet connections are supported?

2 × Ø150 mm or 1 × Ø200 mm.

What is the dust collection capacity?

Pull-out dust drawer with a capacity of 10 litres.

Is a power outlet included?

No. The type of power outlet is specified as “Not included”.

Technical specifications

| Model | TV-1200 (OL) EU |

| Part number | 113050B1 |

| Motor | 3-phase TEFC (continuous duty) |

| Power | 2.2 kW |

| Voltage / frequency | 400 V / 50 Hz |

| Phase | 3 |

| Current | 4.6 A |

| Airflow | 2,000 m³/h |

| Sound level | 74 dB(A) |

| Suction inlet | 2 × Ø150 mm or 1 × Ø200 mm |

| Filter cleaning | Manual Reverse Purge (MRP) |

| Standard filtration | Spark trap + conductive cartridge filter (12 m²) + carbon filter |

| Dust collection | Pull-out dust drawer – 10 litres |

| Cable length | 10 m |

| Dimensions (H × W × L) | 119 × 86 × 135 cm |

| Weight | 215 kg |

| Power outlet | Not included |