The Dust Collector A dust collector is neither a traditional industrial vacuum cleaner nor a conventional ventilation system. It is a category of equipment in its own right, developed for production environments where dust is...

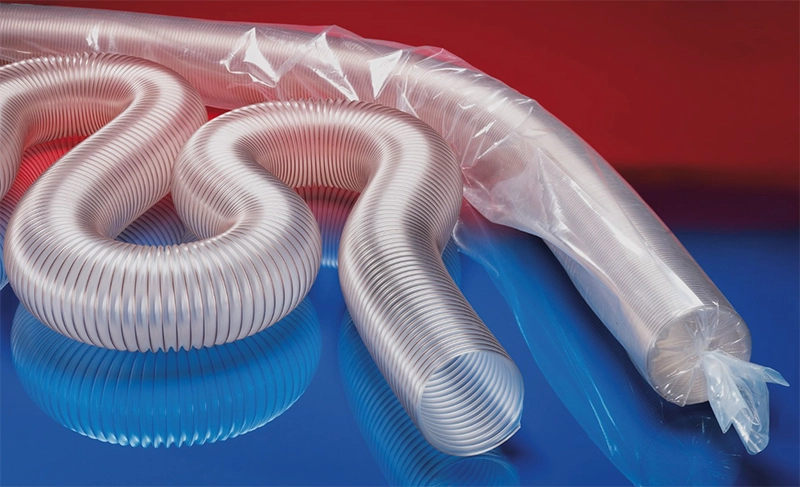

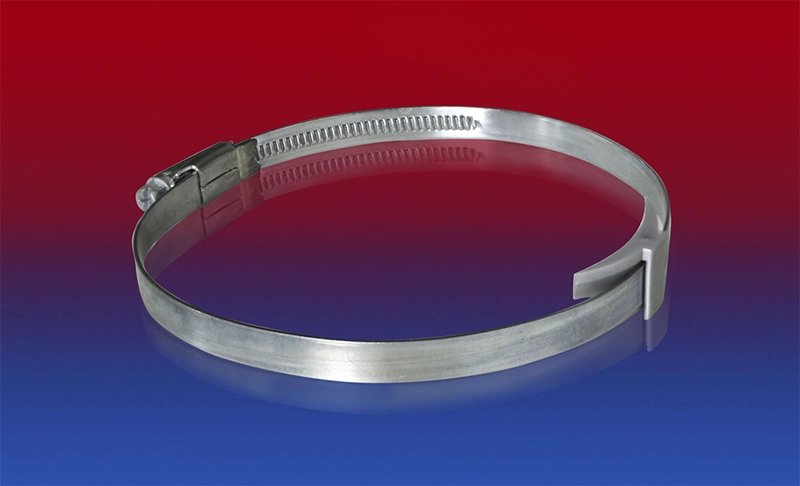

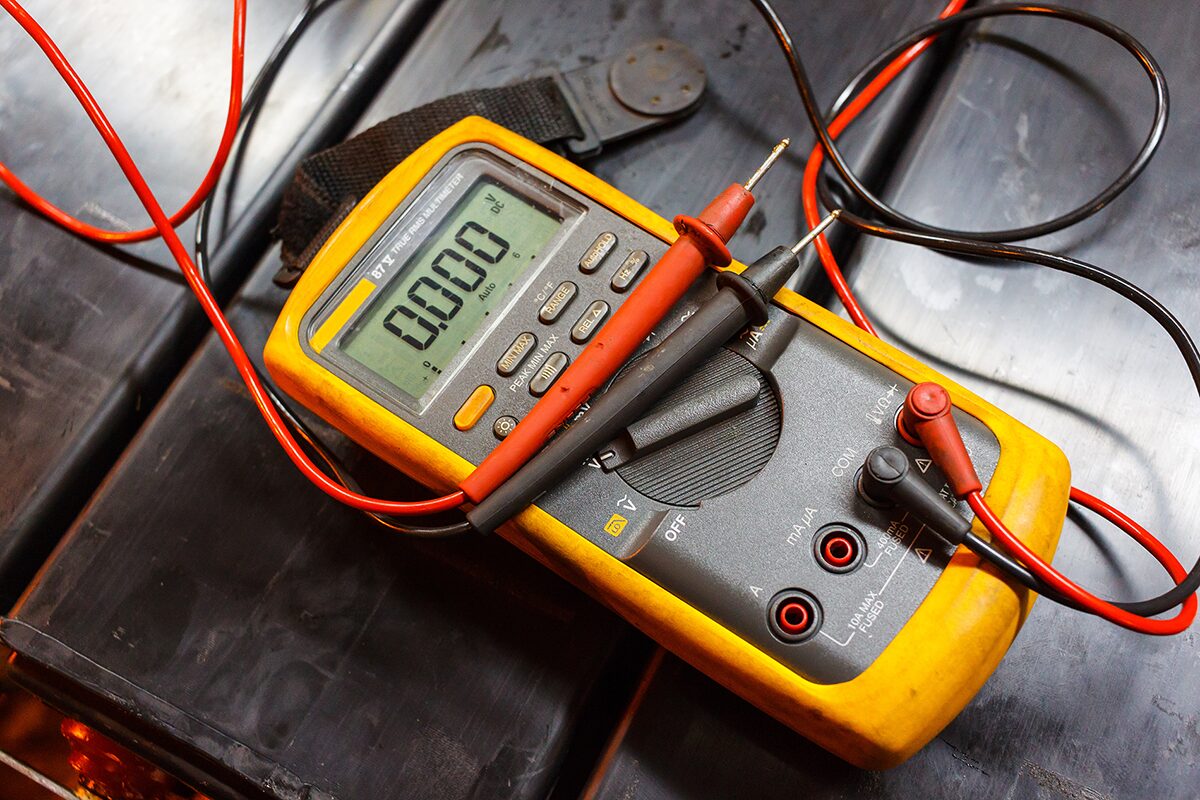

Our OEM customers receive hoses, couplings and accessories fully assembled and factory-tested, so the components can be integrated directly into their production without any additional adjustment. This saves assembly time, ensures consistent quality, and provides documented electrical continuity – especially in ATEX-classified installations.

We work closely with both designers and technicians to adapt lengths, materials and coupling types to each specific machine or process.

OEM solutions can be labelled, packaged and documented according to the customer’s own specifications, ready for installation on the production line.

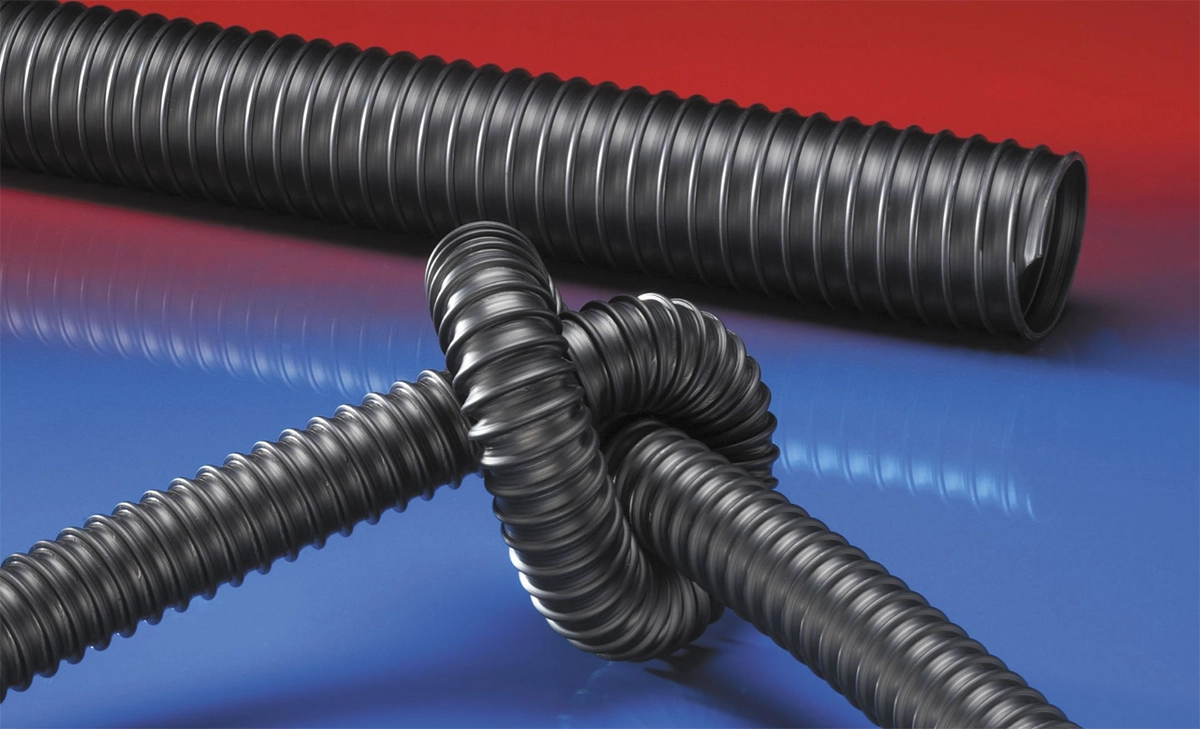

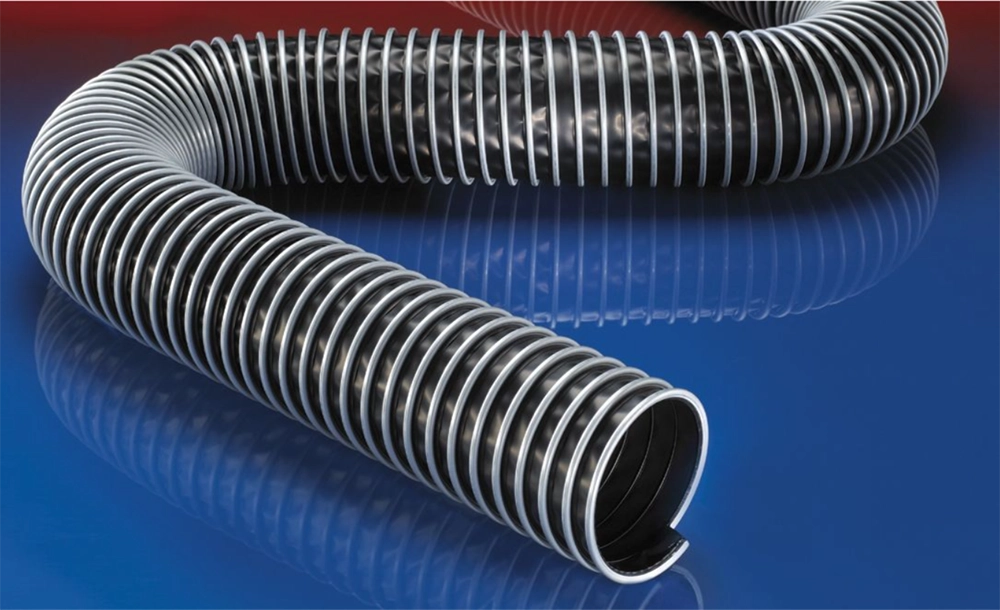

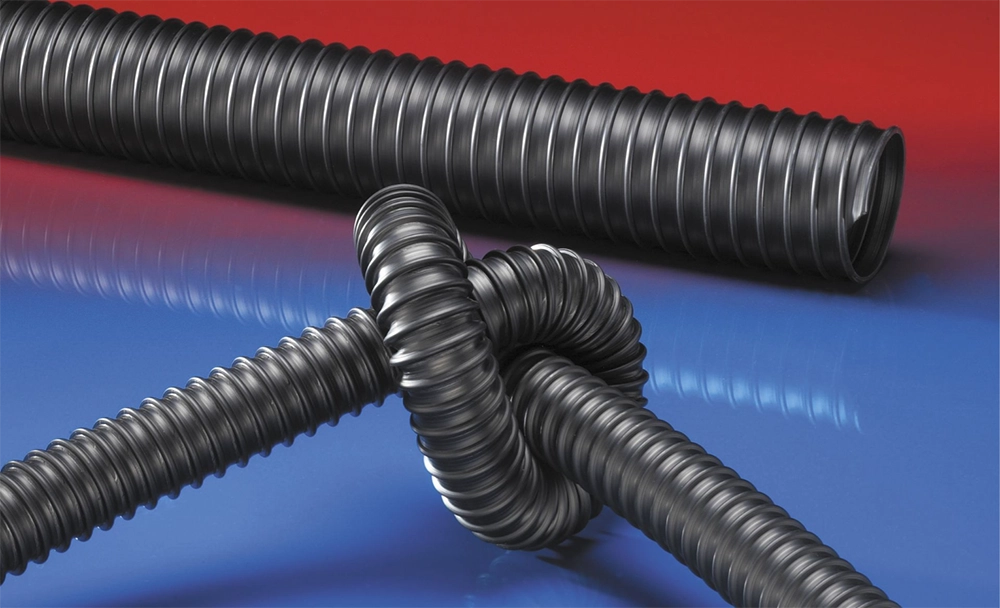

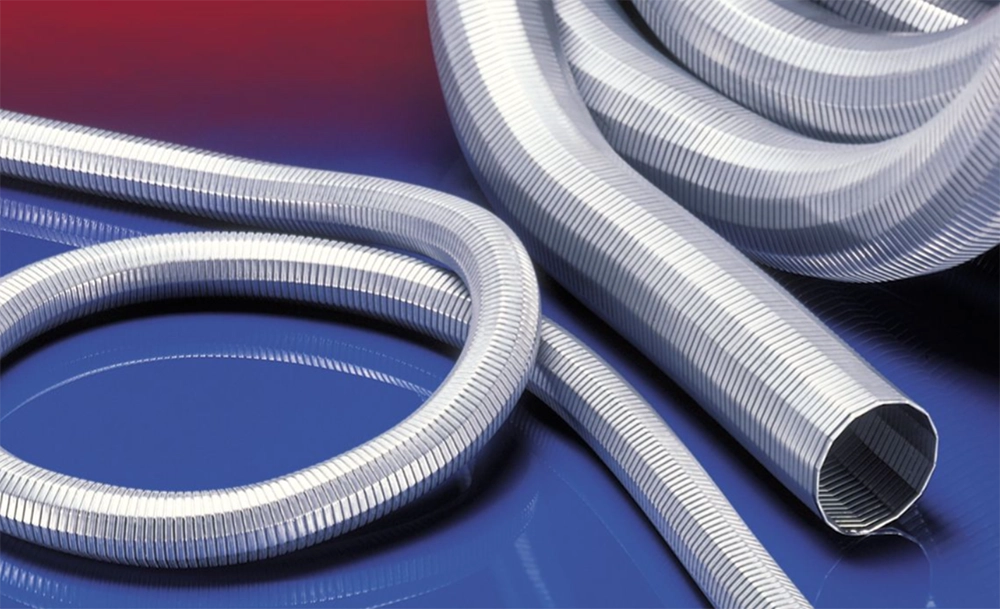

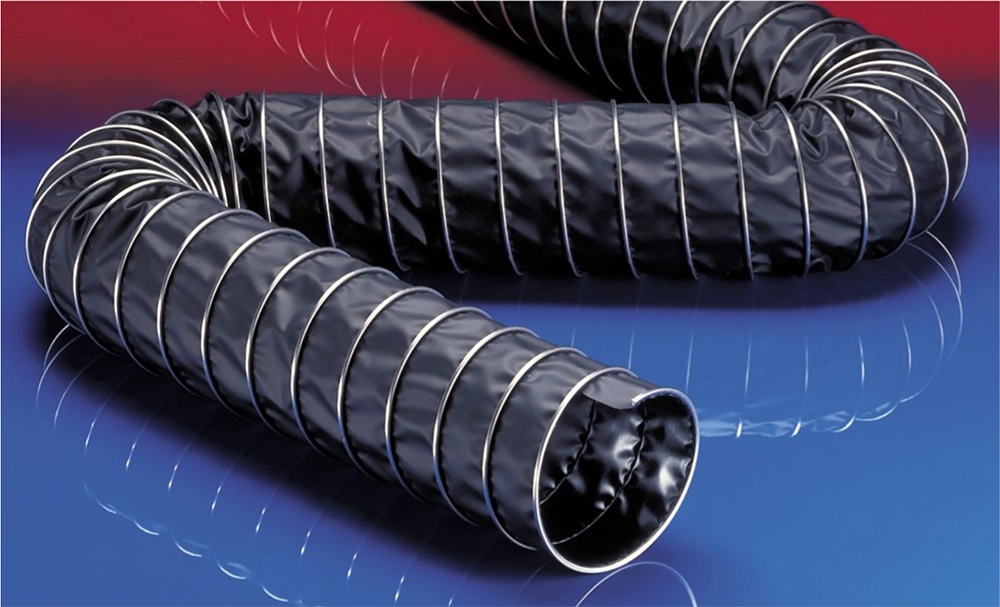

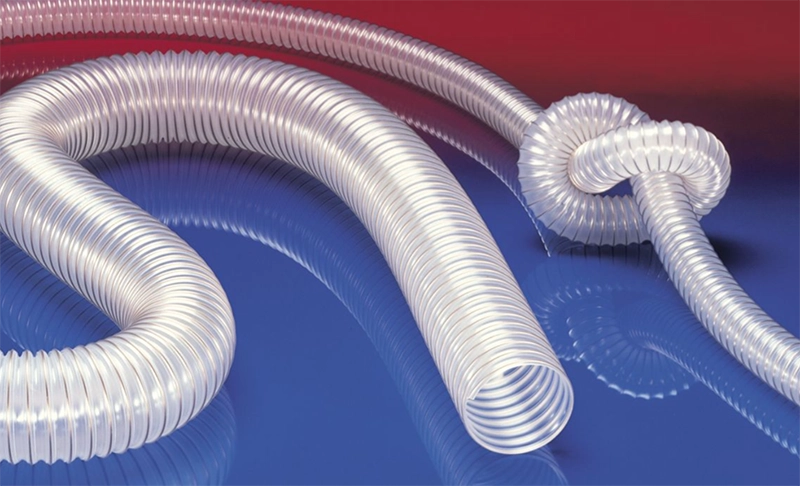

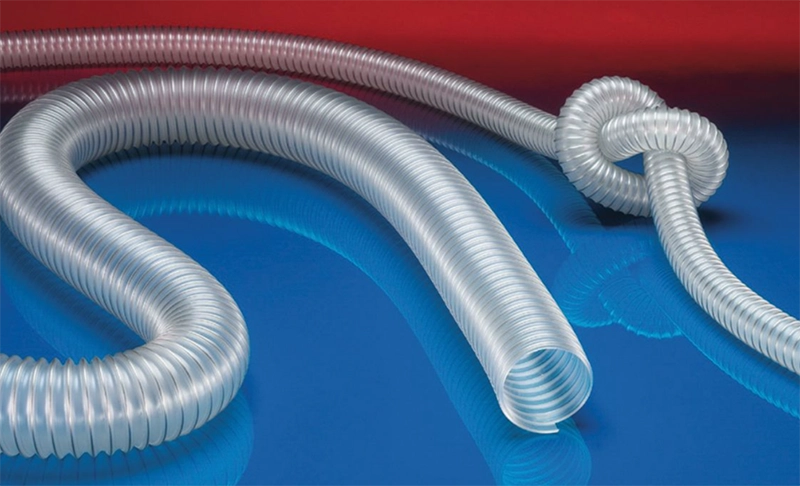

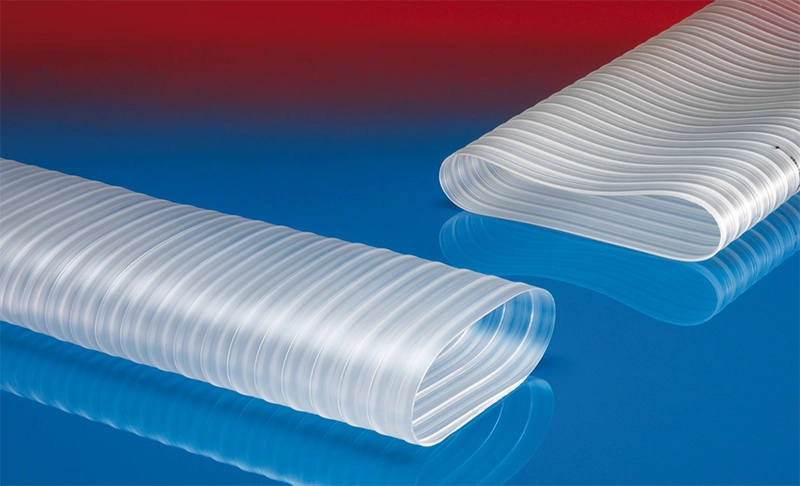

The OEM solutions include EC and AS industrial hoses, ATEX hoses, and custom-built hoses for machine manufacturers.