How about accessories in ATEX zones?

Are there requirements for accessories and hoses in ATEX zones? Yes. Clear, measurable, and binding requirements. Accessories must comply with the ATEX Directive 2014/34/EU and meet the technical requirements in EN 60079-32-1, EN ISO 80079-36/-37, and EN 1127-1.

But don’t get caught up in directives and standards just yet. This article prepares you to understand the requirements – and find solutions that work in real life. Not just on paper. Not just in theory. But in your daily operations.

Every single day, hoses, couplings, and nozzles are used in explosive environments that shouldn’t be there. Not because anyone wants to cause an explosion – but because many simply aren’t aware that it’s the accessories that most often fail. Not the vacuum cleaner.

When talking about ATEX and vacuum cleaners, most people immediately think of explosion-proof motors, correct zone classification, and major technical decisions. But one of the most important – and most overlooked – elements is something much more practical: hoses, nozzles, and couplings. Even the best-certified vacuum cleaner is only as safe as the accessories it is connected to. If the hose is not fully conductive or if the grounding is broken in a loose coupling, the entire ATEX safety setup is compromised – often without anyone noticing.

Common mistakes we see again and again

Many setups look correct at first glance. The accessories are attached, the hoses are black, and the nozzle looks professional. But upon closer inspection, issues are revealed that make the equipment unsuitable for ATEX zones in practice.

A classic example is galvanized steel pipes, often chosen to save costs. While they are technically conductive, they pose a risk in ATEX zones because the galvanized coating can create sparks from impact or friction – for example, if the pipe strikes other metal parts or if hard particles move rapidly through the system. The zinc coating is brittle and can crack over time – increasing the risk of ignition sources.

We also see plastic nozzles that lack conductive properties. While they work fine for regular dust, they are directly dangerous in explosive areas because they can’t dissipate static electricity.

Non-conductive hoses are another common error. This is especially true for cheap models where only the exterior is treated to be anti-static – while the interior, where the dust flows, lacks conductive properties. This results in charge buildup that cannot be dissipated.

Lastly, we often see couplings without proper grounding or measurement points. This means you can’t document or measure the grounding chain – and in practice, the connection is often broken at one or more points.

Why antistatic isn’t enough

It’s not uncommon for someone with good intentions to point at a black hose and say: “Don’t worry, it’s antistatic.” But that doesn’t mean it’s safe.

An antistatic surface reduces static buildup – but it doesn’t necessarily mean the hose is conductive. And that’s exactly what matters in ATEX zones: a continuous, electrically conductive chain that can effectively discharge charges from nozzle to vacuum cleaner.

To ensure proper safety, you must be able to measure and document grounding. According to EN 60079-32-2, the entire vacuum cleaner frame, motor housing, wheels, etc., must have a total ground resistance of ≤ 10⁶ Ω. EN 17348:2022 adds a specific requirement for parts in direct contact with the dust flow – such as hoses, filters, and gaskets – where resistance must be < 10⁸ Ω.

In short: ≤ 10⁶ Ω is the requirement for the whole system – a very low resistance that allows current to flow easily to ground. < 10⁸ Ω applies only to parts in contact with the dust flow, such as hoses and filters. It’s a higher value but still low enough to safely dissipate static electricity.

The problem is that this chain is often broken by small things: a loose coupling, an improperly tightened hose clamp, or a grounding wire that isn’t secured. We also see setups where couplings are glued onto the hose, with no electrical contact between the hose’s conductive spiral core and the coupling. It may feel secure – but is effectively isolated.

These kinds of errors aren’t visible – but they can be measured. And they should be, before using the equipment in ATEX zones.

Not sure how to measure correctly – or what “under 10⁶ ohms” actually means in practice? Then read our article: “What does Ohm mean in practice?” – a practical guide to grounding and safe vacuuming.

Material choices and their consequences

When choosing hoses and nozzles for ATEX environments, it’s not just about diameter and flexibility. It’s very much about materials – and how they behave, both electrically and mechanically.

Hoses come in many variations: PU (polyurethane), TPE, rubber, or blends with embedded copper wire. The best solutions have a continuous conductive structure, either through an internal spiral or the hose material itself. The key is that the hose can discharge static from inlet to outlet – and that you can document it.

When it comes to pipes and nozzles, many choose based on weight or price. Aluminum is light, galvanized steel is cheap. But stainless steel is by far the safest choice in ATEX zones. It has low spark risk, high mechanical strength, and retains its properties over time. Conductive rubber can also be used if tested and documented. Aluminum may spark on impact, and the galvanization on cheaper steel pipes can crack and pose friction risks.

Grounding in practice

An ATEX-certified vacuum cleaner is not, by itself, a safety guarantee. What matters is whether the entire setup – including hose, couplings, and nozzle – functions as a single electrically connected system that can effectively dissipate static electricity.

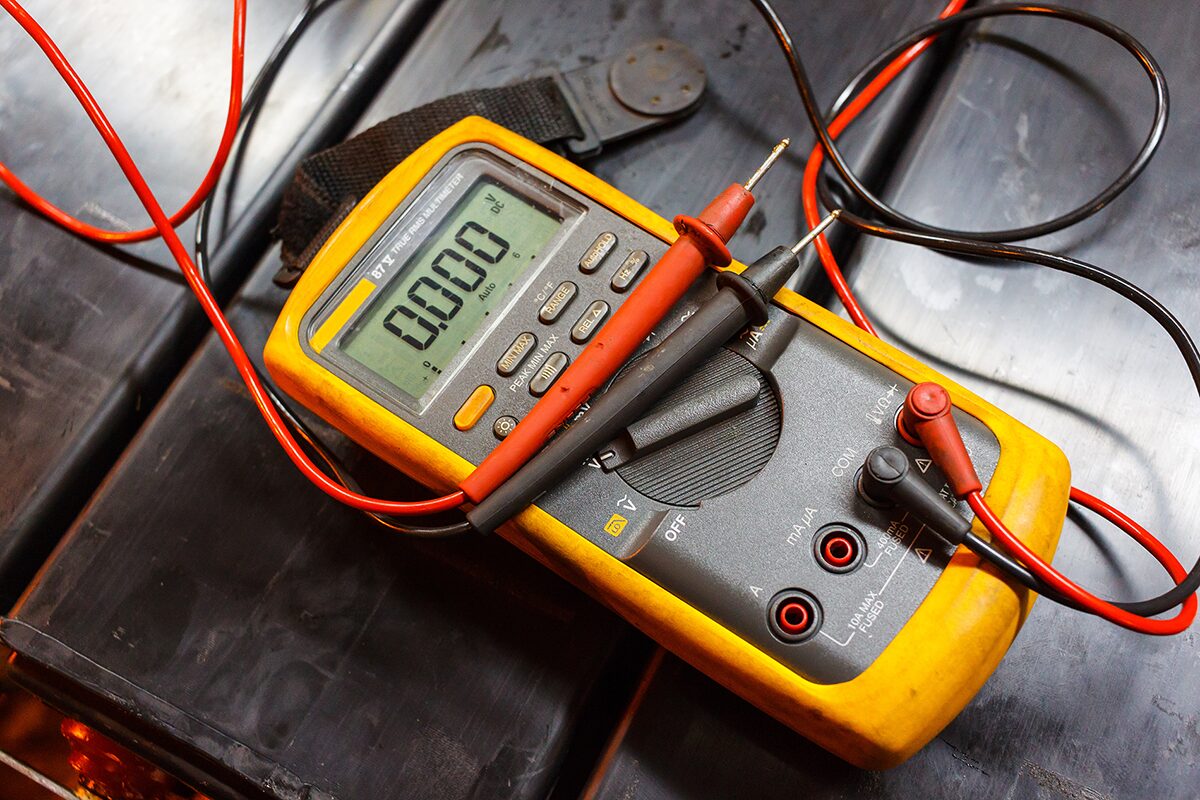

To document this, you must measure electrical resistance from the vacuum cleaner frame to the outermost point of the accessory. This requires a fully conductive hose, mechanical contact in the couplings, and a visible measurement point – such as a grounding bolt – where you can connect your multimeter and read resistance.

As a rule of thumb, resistance must not exceed 10⁶ ohms. But that number isn’t a guarantee by itself – it depends on several factors, including zone classification and material type. More important is that resistance is low and stable – and that you can check it.

How to test the equipment yourself: – Measure resistance from the grounding bolt to the nozzle – Record the value and date in a logbook – Repeat the measurement after servicing, cleaning, or hose replacement

It’s not enough that hoses and accessories were perfect when delivered. Wear, buildup, vibrations, and temperature fluctuations can all alter electrical properties over time – which is why you should have a routine for follow-up. Measure, document, and repeat – or replace the accessories on a set schedule.

Not sure whether something is still safe? Then measure conductivity. And if you’re still in doubt – replace the hose, coupling, or nozzle. It’s better to be safe than to assume everything is still working.

Are you in control of your ATEX accessories?

But what do you actually do once the equipment is in operation? When a new vacuum cleaner is delivered, everything might look correct. The hose is included, the nozzle fits, and the coupling is mounted. And it’s rarely at this stage that things go wrong. The problems appear later – after weeks or months of use, when conductivity has gradually been compromised by wear, deposits, and loose connections.

The first thing you should do is ensure that the hose you’re using is actually conductive. Not just labeled “antistatic,” but measured and documented as conductive throughout. This requires a continuous conductive structure – typically with embedded copper wire or conductive plastic. You should be able to measure low resistance from the end of the hose all the way to the vacuum cleaner frame.

Next, make sure there’s electrical contact between the coupling and the conductive part of the hose. Many couplings are glued in place, which can insulate rather than connect. What matters is that the contact is electrically conductive – either via a compression fitting, a conductive sleeve, or direct metal-to-metal contact.

Nozzles and pipes also require attention. Aluminum and galvanized steel are often used, but stainless steel is usually the best choice in ATEX zones, both in terms of spark safety and durability. Conductive rubber can also be used if tested and documented.

Finally: Do you have a measurement point? A spot on the frame where you can check resistance from the vacuum cleaner to the furthest accessory using a multimeter? If not, you’re missing a basic tool for maintaining your own safety.

A real-life example

Let’s take a concrete example.

An operator uses a mobile ATEX vacuum cleaner to collect combustible plastic dust. The equipment is correctly configured: the hose is conductive with embedded copper wire, the couplings are mechanically attached with metal contact to the hose, and the nozzle is made of stainless steel. From the vacuum cleaner frame, a ground wire runs all the way to the nozzle, and there is a visible measurement point for routine checks.

At delivery, resistance is measured at under 10⁴ ohms. Six months later, the measurement shows 7 × 10⁵ ohms – still acceptable, but clearly higher. After one year, the connection is broken in a coupling, and resistance can no longer be measured. The issue is detected because the company has a routine for checks.

Without that routine – and without a measurement point – the operator could have continued for months without realizing the system was no longer ATEX-safe.

Standards and directives – what do the rules actually say?

This article has deliberately focused on practice. But ATEX safety doesn’t stand alone – it is anchored in international rules and standards that provide clear guidelines for how to select, use, and inspect equipment in explosive areas.

The most important are: – ATEX Directive 2014/34/EU, which applies to all equipment used in explosive environments – including vacuum cleaners and accessories. – EN 60079-32-1, which addresses risks related to static electricity and how to reduce or eliminate them. It focuses on material choices, grounding methods, and control measures. – EN ISO 80079-36/-37, which define Equipment Protection Levels (EPL) and set requirements for non-electrical equipment – such as hoses, couplings, and mechanical components. – EN 1127-1, the basic standard for explosion prevention and risk assessment – and often used as a reference in workplace safety.

You don’t need to read them cover to cover. But you should be aware they exist – and use them as technical support when making decisions about equipment and accessories. At Particulair, we work with them every day and are happy to help translate regulations into practical solutions.

What do you do when something is uncertain?

We get it. The hose usually isn’t the first thing that gets checked. Most people start with the machine, the filter, or the motor type. But in reality, it’s often the accessories that fail – and pose the greatest risk.

So you should ask yourself: Do I have a routine for checking conductivity and grounding? Do I test the system regularly – or just assume it still works?

If in doubt, measure. And if you’re still in doubt – replace. Not because the equipment is necessarily faulty, but because you can no longer be sure it’s working as it should. ATEX safety isn’t just about regulations. It’s about awareness.

Conclusion and next steps

ATEX zones aren’t mysterious spaces. They are risk areas – and the risk doesn’t disappear with a sticker or a CE mark. It only goes away when the entire chain – from vacuum unit to nozzle – is thoughtfully designed, verified, and built with respect for materials, functionality, and electrical discharge.

ATEX safety doesn’t begin with the manual. It starts in practice – when you choose, use, and inspect your equipment. And especially when you remember that it’s often the small details that determine whether a system remains safe over time.

Whether you have a single setup or a full production line, we’re happy to help you get started with a measurement plan and the right choice of ATEX accessories. Contact us – and let’s have a practical conversation about your safety.

Thomas Lyng

If you have any questions, feel free to contact us.